Pandrol, a global rail expert, has launched a range of next generation clip drivers, designed to dramatically increase the speed and efficiency of clipping and unclipping rail fastening systems.

Featuring three new clip driver products, the CD200 IQ, the CD300 IQ, and the CD400SP IQ, the equipment represents a significant upgrade on the first generation models. Designed with efficiency in mind, each machine features a ‘smart system’ incorporating an intelligent control system which monitors its operation and actively controls the clipping operation. The control system provides information on clips installed and operating hours, while also preventing any incorrect usage of the machine.

With the CD200 IQ clipping up to 2 clips per cycle at a rate of 20 sleepers per minute, and the CD300 IQ and CD400SP IQ clipping up to 4 clips per cycle at 40 and 30 sleepers per minute respectively, the new intelligent systems offer a wide range of options for clipping at a speed and efficiency that suits any installation and preferred work method.

The range of modular products – weighing 117kg, 975kg, and 3075kg respectively – can be utilised for a broad range of tracks and can be used in conjunction with Pandrol’s full range of Fastclip and e-clip products.

The new CD300 IQ Road Rail Vehicle clipping attachment vastly improves the clipping capacity and offers a number of features that help the operator to ensure a good quality of work.

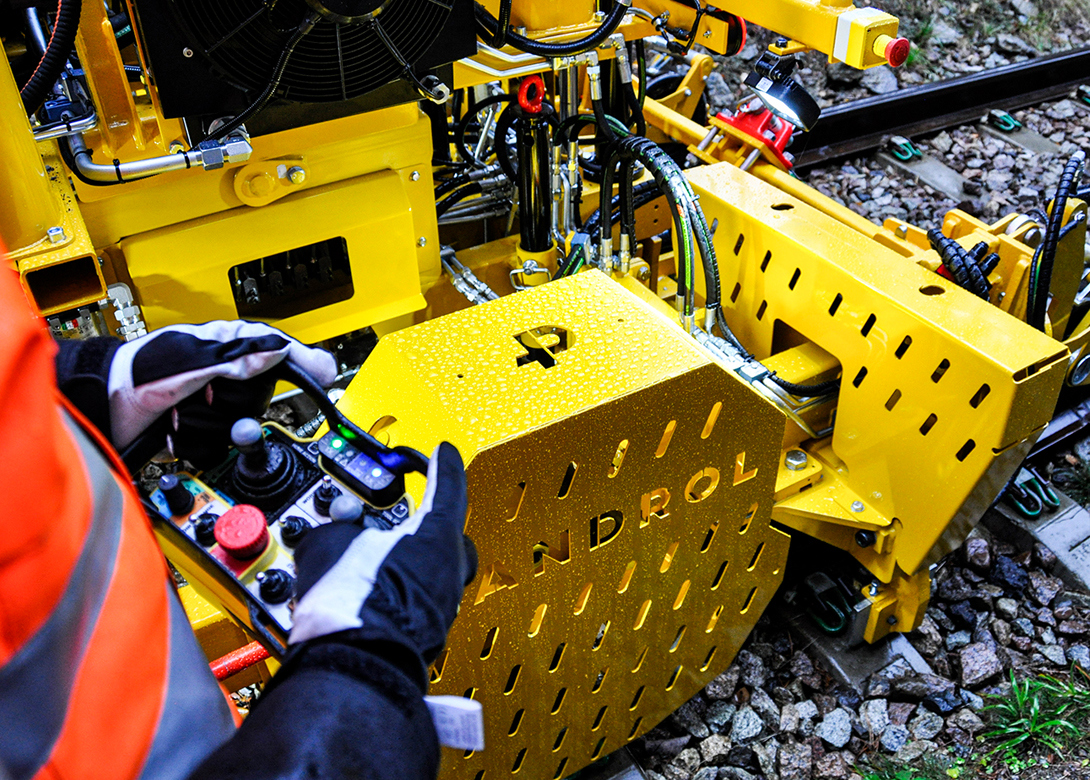

The self-propelled CD400SP IQ is a clipping machine which is operated by a remote control. This second generation of Clip Driver CD400SP has a new EU Stage 5 diesel engine which is more fuel efficient and reduces the carbon footprint.

Erika Berg, managing director of Pandrol’s Swedish operations, where the new range was developed, said: “The new smart system in the IQ range of clip drivers really does make all the difference. Beyond the robustness and the versatility of the machines, and the logging of operations, this new generation of clip driver offers a built-in diagnostic system to vastly improve the maintenance, repair and testing effectiveness.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.