Among the results achieved by Growermetal’s R&D team, the Grower Tenkeep® – a security washer with two surfaces of different geometries that offer stability, excellent locking and higher untightening torque – represents the ultimate flagship product in the company’s range.

From its headquarters in Calco, between Bergamo and Milan, Growermetal SpA has grown to define its path as one of the most important global leading manufacturers in the production of spring, railway and security washers, as well as blanked parts according to customers’ drawings.

Since its establishment in 1950, the company has been run by the Cattaneo family and has been driven by the will to meet the quality and safety needs of its partners with innovative technologies and proactive services.

To keep itself always in step with the times, Growermetal has merged its strong heritage in fastening solutions with the continuous investment in research and development laboratories. This transformational process has involved many aspects of its business, including boosting the production in many ways – from the progressive automatisation of the manufacturing process, to the design and creation of products suitable to the most extreme applications – such as the Grower TenKeep®.

Grower TenKeep®

The Grower TenKeep® is a true expression of the technical know-how acquired over the years by the Italian company. This flagship product was introduced to the market in 2019, defining a new boundary for the fastener industry. The launch received a very positive response, with the Grower TenKeep® also winning the Route to Fastener Innovation Competition award at Fastener Fair Stuttgart in 2019, which was a great acknowledgement for Growermetal.

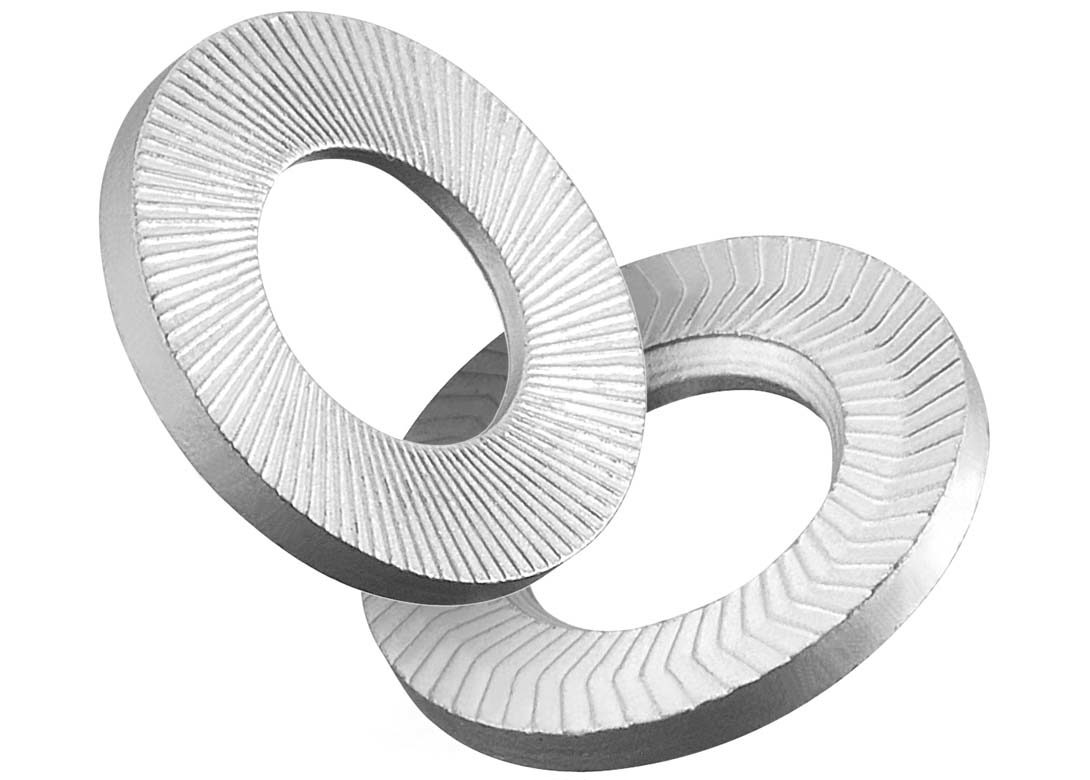

One of the main point of interests of the Grower TenKeep® is its geometry – made of a single high performing flat washer with two surfaces that include knurls of different geometry. The product is designed to guarantee great stability and maximum performance against unscrewing of the bolted joints.

Through advanced testing and tools, Grower TenKeep® has shown great efficiency in preventing loosening, even in the most challenging conditions, for example in presence of extreme vibrations and dynamic loads.

Where does the secret of this incredible tightening lie? Growermetal points out that in some ways, it is all about numbers and testing. Before defining the final design of the two sides of the security washer, more than 400 types of different geometry were tested by the researchers and experts of Growermetal, until they found the right shape.

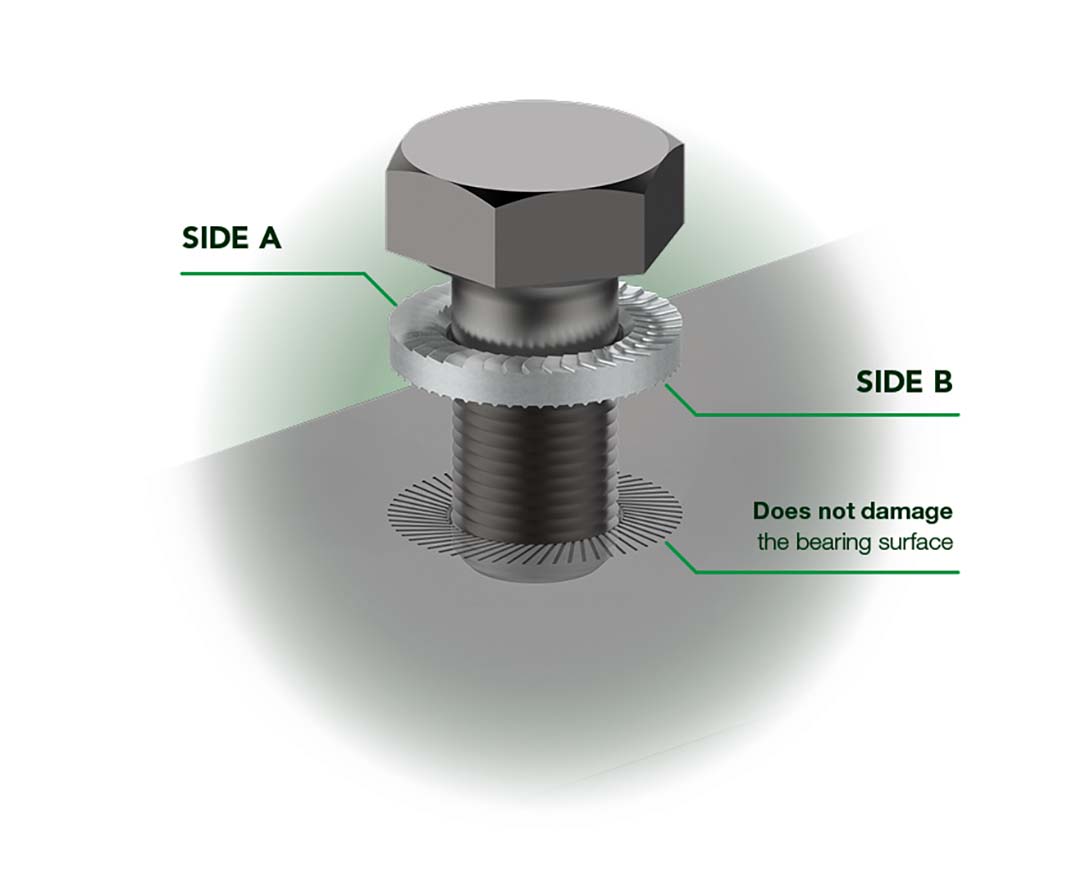

‘Side A’ of the washer is put on the head of the screw or nut side and slides against the surface of the underhead of the screw/nut when tightening the bolted joint. Due to its particular advanced serration geometry this side is also known as the ‘boomerang side’ and is able to counteract very efficiently the loosening of the bolted joint connection. In addition, the chamfer on the hole of this side avoids any interference with the radius under the screw head and allows the user to orientate the washer correctly.

The other side of the washer, referred to as ‘Side B’, is in contact with the bearing surface and is characterised by a knurling that offers an exceptional grip, becoming immediately solid with the material when the bolted joint is tightened. Thanks to this characteristic, the washer remains permanently solid to the bearing surface.

Results and advantages

The features of the Grower TenKeep® give proof of their value when used in concrete applications, where it shows at least three main remarkable advantages. First of all, regardless of the material or mechanical characteristics of the bearing surface, the friction conditions are defined and uniform, with excellent locking even in the presence of vibrations and dynamic loads. As a consequence, the tightening torque to be applied in order to achieve the desired screw preload is always the same.

Next, the Grower TenKeep® washer does not rotate and thus does not damage the bearing surface during tightening and untightening of the bolted joint, even on galvanised, painted or soft surfaces. Finally, focusing on performance, the third advantage is a significant higher untightening torque, at least +40% more than the tightening torque.

Other additional benefits of the flat washer include the minimum space requirement (with the washer always remaining inside the screw head); the suitability for application with embedded holes and the possibility to use the washer several times without loss in performance; plus, the chamfer on the ‘Side A’ hole helps the user to correctly position the washer and, due to the special design of the hole geometry, it avoids any interference of the hole of the washer with the radius under the head of every bolt type, according to ISO and DIN standards.

In order to bring the stability of these safety flat washers into different applications and on different surfaces and materials, Grower TenKeep® safety washers are manufactured by Growermetal in different versions and can be used with bolts of all strength classes up to 12.9.

The three standard series includes:

Grower TenKeep® M Medium Series: Ideal for hexagonal head bolts. It is designed for applications with threaded hole and hexagonal head screw and with through-hole and hexagonal head bolt.

Grower TenKeep® L Large Series: Suitable for flange-headed bolts and for bearing surfaces made of soft materials like aluminium and plastics. It is designed for application with wide holes and flanged head screws.

Grower TenKeep® C Cylindrical Series: Used for cylindrical head bolts. It is designed for applications with bored hole and cylindrical head screw.

Testing and treatments

In order to resist the most demanding environments and challenging applications, Grower TenKeep® washers are made of carbon steel, quenched and tempered with a surface and core hardness of 510 HV – 560 HV 10. Furthermore, the range is supplied with the zinc flake coating Delta Protekt® KL120, which is one of the highest performing products of Dörken and guarantees a corrosion resistant performance of 1,000 hours minimum, according to neutral salt spray tests in compliance with ISO 9227.

The cooperation between Growermetal and Dörken has not only provided this extremely resistant surface treatment to the Grower TenKeep® washers, it has also brought further testing. The results presented during the annual Dörken Days event in Frankfurt, Germany, proved the qualities of the product – taking into account several factors that play a significant role in the fastener industry, such as the coefficient of friction of the bolted joint connection according to the VW 01131 standard and the loosening behaviour under strain conditions.

The numerous tests confirmed that Grower TenKeep® safety washers keep the preload in presence of vibrations and show a very good performance on different types of bearing surfaces – without any slipping, even in harsh conditions. As well as showing a good loosening behaviour and no stick-slip effects.

Among the tests that have been run on this innovative product, self-loosening resistant tests play an essential role in order to manufacture high-quality products. Since vibrations are one of the most critical and challenging issues in bolted joint connection, Grower TenKeep® safety washers underwent the so called ‘Helicopter’ loosening resistance test, which was carried out at the CETIM (Technical Centre for Mechanical Industry) in France.

Once more, the remarkable results of the Grower TenKeep® during the ‘Helicopter test’ demonstrated a very good level of untightening torque (break-away torque) in comparison to the tightening one. After 10,000 cycles of the ‘Helicopter test’, the results highlighted the great advantage in performance of the break-away torque (residual torque) of the Grower TenKeep® when compared to the tightening torque (initial torque).

“These outstanding results, together with the excellent price/performance ratio, has contributed to the good response of the sector to Grower TenKeep® saftey washers,” states Paolo Cattaneo, CEO of Growermetal. “The product also obtained the European patent for industrial invention in 2021, which represented a great achievement for Growermetal and a valuable recognition of our R&D team’s brilliant innovation.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.