Böllhoff is a supplier and international service provider for fastening and assembly technology and a recognised partner to railcar manufacturers and their suppliers.

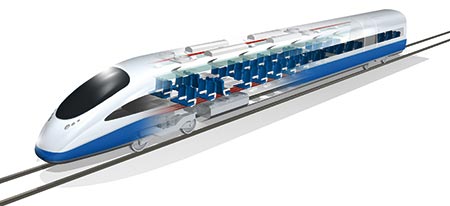

In order to remain competitive, railway operators have to be able to transport more and more people and goods with ever greater speed, reliability and efficiency. This, in turn, increases the performance and specification of the rail vehicles and transport systems.

Project related business, with individual customers involving highly complex technology and relatively low batch sizes, reflect the particular challenges of the railway and transportation industry. At the same time, global competition brings immense pressure on costs and innovation. Therefore, technological potential and innovative ability ultimately determine the success of railcar manufacturers and their suppliers.

The Böllhoff Group adopted these challenging guidelines early on and says it was one of the first companies in the world to be IRIS-certified. This distinction represented another major milestone for Böllhoff in its systematic quality management programme.

The Böllhoff ECOTECH service (Economic Technical Engineering) enables railcar manufacturers and suppliers to benefit from technical advice from Böllhoff’s engineers. Their know-how and advice covers all areas of fastener technology, corrosion protection and screw retention for the railway industry.

Böllhoff explains that the simultaneous standardisation and optimisation of fasteners in the development stage simplifies assembly and reduces tool costs. In view of the ever faster technological development and the increased competitive pressure, this service is a crucial advantage in the railway industry.

Successfully implemented projects include a newly developed element that increased the assembly productivity at a full-service provider of railway technology and services. Another project included the worldwide market leader in rail transport sector and the use of riveting technology, which revolutionised the whole roof construction.

“Ever shorter product cycles, the use of new lightweight and environmentally friendly materials and an ever changing division of labour require innovative capacity and a high degree of flexibility. Future-oriented and safe mobility sets high technological requirements, which Böllhoff, as a specialist in fastening technology, follows.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.