Here, TFC, a supplier of fastening products and services, outlines the advantages of using wave springs and why they should be the go-to when preloading a bearing.

A bearing is designed to move freely and has multiple moving parts that work together as one unit. However, a tolerance stack up from both the manufacturing and assembly processes can quickly cause issues. This is where preloading comes in, where a sustained axial load is provided to the bearing. Overall, the goal of preloading is to prolong bearing life and, therefore, your application.

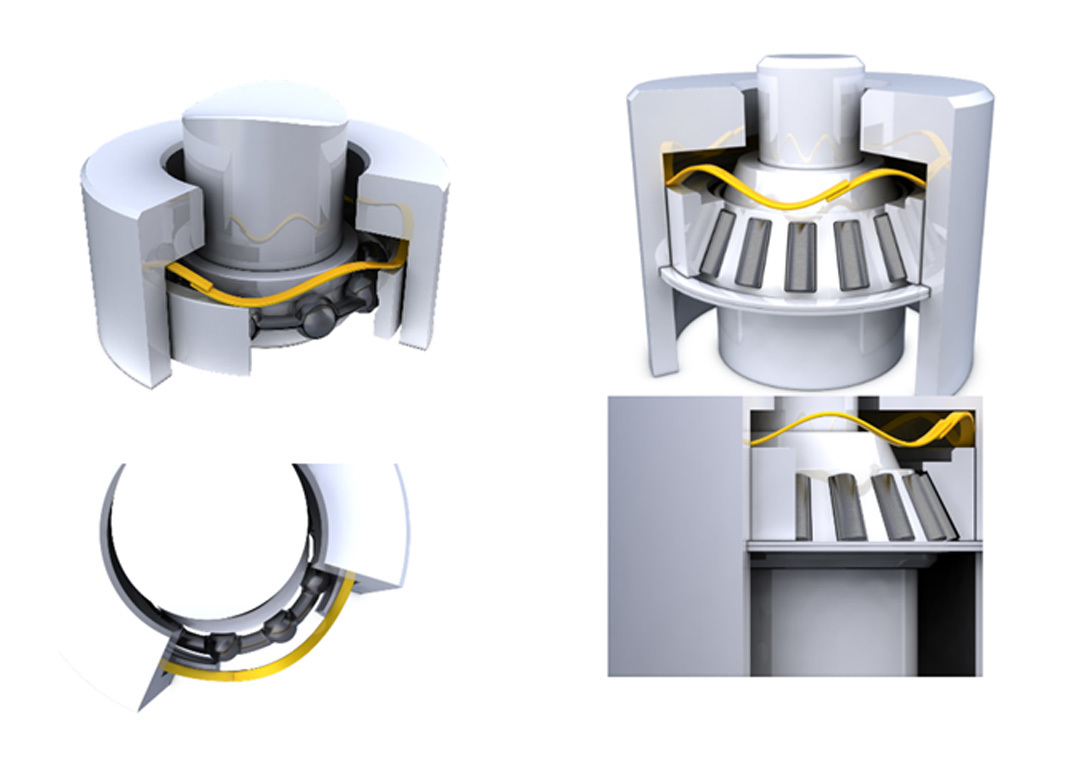

There are two main methods to preload a bearing. The first is solid preload, which is achieved by holding inner and outer races in place with a locking mechanism. The more common, simpler, and less expensive method is spring preload, which is achieved by using a spring to apply a constant axial load on one side. Controlling play is necessary to maintain bearing functionality and longevity.

Preloading a bearing provides constant contact between the bearing type and bearing races. The sustained load provided by the spring eliminates axial and radial play, among other benefits. Every application is unique, so selecting the proper wave spring important. It’s important to consider overall tolerances, as placing too much preload on the bearing can reduce longevity, while too little can cause higher noise output in high-vibration systems.

Using a spring for preload is critical for high-precision or high-speed applications, as it essentially eliminates the need for holding tighter tolerances and helps withstand high operating speeds. Thanks to the wave design, there is greater load sharing between the bearing which results in reduced wear. Such a design also means a quieter assembly, even in high-vibration applications.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.