By Dr Bill Eccles, Bolt Science

A question was recently asked if it was possible for a loose nut to act against gravity and rotate off a bolt. Such instances can happen, but only under dynamic load conditions, i.e. the bolt being subjected to some degree of vibration.

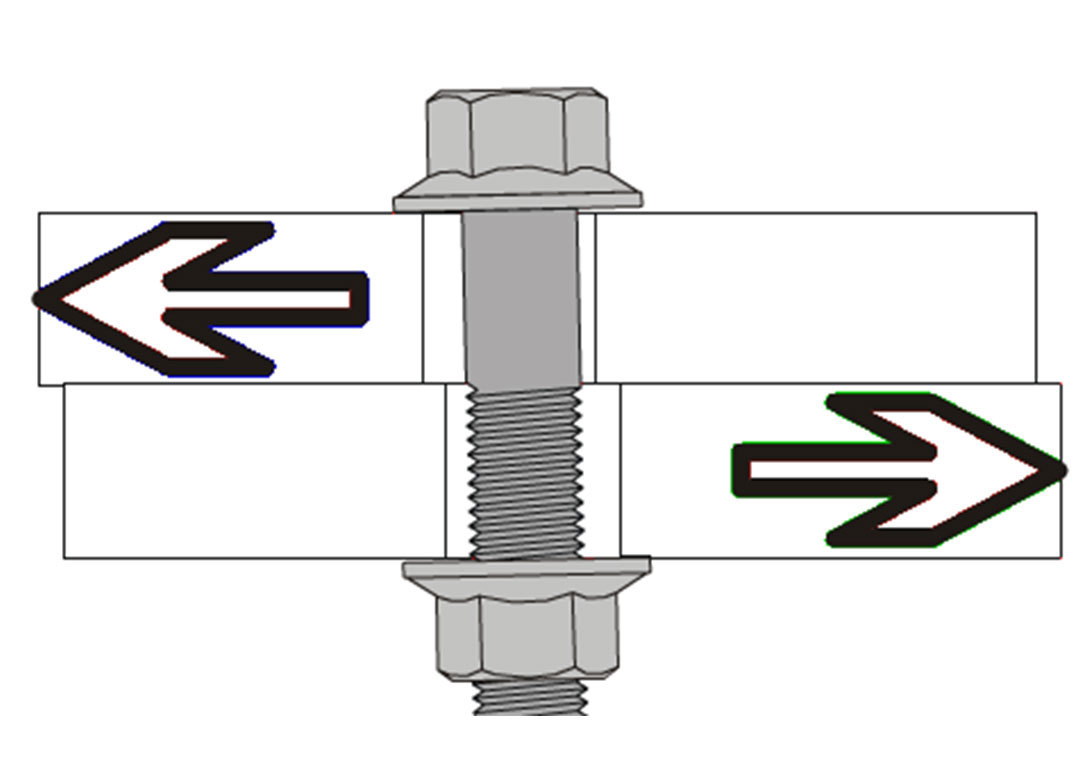

The process of previously tightened nuts coming loose is now reasonably well understood. Relaxation effects can occur (such as creep, stress relaxation and embedding) in which the preload created by the tightening process is lost, or partially lost, without the nut rotating. Self-loosening is when the nut rotation results in the preload being lost. The usual mechanism for self-loosening is transverse joint movement. Once the preload is lost, the question is at what point will the nut become detached from the bolt? Accidents can occur once the nut is detached and the joint falls apart.

Researchers have looked at the conditions that can cause nut rotation on bolts once the preload has been lost. Researchers in 1996 experimentally investigated the response of threaded fasteners to axial harmonic vibration. They found that the direction of rotation of a fastener, either in the loosening or tightening direction, depended upon the frequency and amplitude of the vibratory input.

The tests were performed on ¼ - 28 UNF threads that were loose, i.e. no preload present. Screws in tapped holes were used rather than a nut on a bolt but there are obvious similarities. Work was also completed to establish a theoretical framework by completing a kinematic analysis of the twisting of threaded components loaded by gravity and subjected to axial harmonic vibration.

Essentially, the rotation is due to the clearance that is present between the threads. It was shown that at high vibration amplitudes, the screw would rotate upwards against gravity. At low amplitudes, the screw would rotate downwards. This work presents a mechanism by which a nut can become detached from a bolt once it is completely loose.

It can be somewhat surprising to see a nut rotating against gravity to fall off a bolt thread. This video shows such a situation.

The bolt contains a small motor that induces vibration, the motor is activated when it is near to a magnetic field. Such bolts are sold as a magic trick but illustrates the principle involved. Normally, when the bolt either held by its head, or is seated on its head, the nut will rotate towards the end of the bolt thread irrespective of the direction of gravity. The direction of rotation of the nut can be altered by changing the vibration amplitude that it experiences. This can be achieved by holding the bolt at the end of the thread rather than at the head. Like the previous research showed, reducing the vibration amplitude can reverse the direction of rotation.

In practice in many applications, if a bolt is experiencing vibration, it is likely to experience varying levels of vibration amplitude that, sooner or later, will result in the nut becoming detached irrespective of whether it will have to act against gravity.

If nuts are retained on the bolt the bolts can fail as a result of wear due to the joint moving or fatigue of the bolts or parts of the joint itself. Usually such failure mechanisms take time allowing opportunity for the loose nuts to be discovered and the issue rectified. When the nuts become detached, catastrophic failure can occur suddenly. Such failures have occurred across most industries, for example with wheels coming off heavy goods vehicles. Detachment of nuts from bolts have resulted in a number of rail accidents involving a loss of life. For example, the Potters Bar accident in 2002 and the Greyrigg accident in 2007 (both in the United Kingdom) were caused by nuts becoming detached from bolts resulting in the trains being derailed and a subsequent loss of life.

In some industries, even when the joint design is adequate, there can be concern that the nuts will not be tightened adequately. Even with a proven design, if the nuts are not tightened sufficiently, the nuts can come loose and subsequently become detached. Nuts having a prevailing torque are frequently used in many applications to help prevent nut detachment. (The prevailing torque is the torque needed to run the nut down the thread before clamping of the joint parts occurs.) This type of nut is sometimes called a self-locking nut. The name is a misnomer since such nuts do not lock the nut to the bolt and so do not necessarily prevent self-loosening.

Under a Junker transverse vibration test, this type of nut tends to self-loosen (rotate) and then stop, retaining a small level of preload. Essentially, the prevailing torque is balancing the loosening torque generated by the transverse slip being experienced. There are two main types of prevailing torque nuts; nylon insert and all-metal. The nylon insert nut, often referred to as a ‘nyloc’ nut, has a plastic ring that generates the prevailing torque. The all metal nut generates a prevailing torque usually by distorting the threads at the top of the nut. A word of warning, if the joint is subjected to axial as well as transverse loading, if the joint is not adequately preloaded, the joint plates can be pulled apart forcing a prevailing torque nut off the bolt thread.

The most effective way to keep nuts on bolts and to prevent bolting issues is to ensure that the nuts are tightened so that a minimum design preload is achieved. The minimum design preload requirement can be established by a joint analysis, with the aid of software such as BOLTCALC, and subsequent testing to ensure that the assumptions made are valid. If this approach is adopted, the locking of the nut to the bolt is achieved by friction. Under such conditions the preload provided by tightening the nut will last for the life of the product.