Rivit’s capacitor discharge welding studs can be used to create joints between bearing pieces and the part to be fastened, such as steel, stainless steel, aluminium, and brass surfaces.

Thanks to the company’s range of welding studs, made of resistant and watertight fastenings, the outer surface on which the application has been performed, remains smooth to safeguard aesthetics.

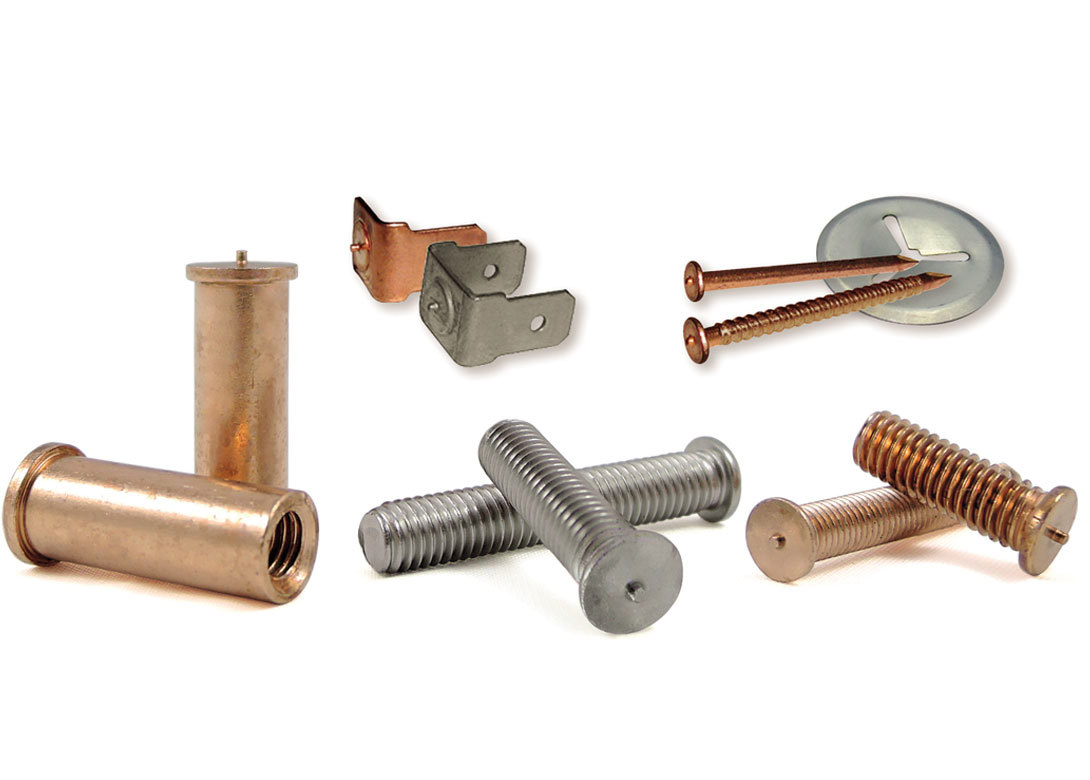

Application is very easy as it does not require accessibility from both sides of the sheet as the products can be blind placed. The studs can also be welded onto plates of the same material, and users can choose from threaded studs, internal thread tapped studs, 1 or 2 contact fastons, and insulation nails, which are available in steel, AISI304 stainless steel, aluminium and brass.

For the installation of the welding studs, Rivit Srl recommends the use of the RIVST80 capacitor discharge studwelding tool for studs up to M8. Being completely electronic it is not subject to any kind of wear, and it automatically stabilises the variations of the line voltage.

The gun, which comes with the tool, works according to the contact welding system and the centering of the studs can be done following an outline, by means of a centering template. The welder weighs 13kg and gun weighs 0.7kg.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.