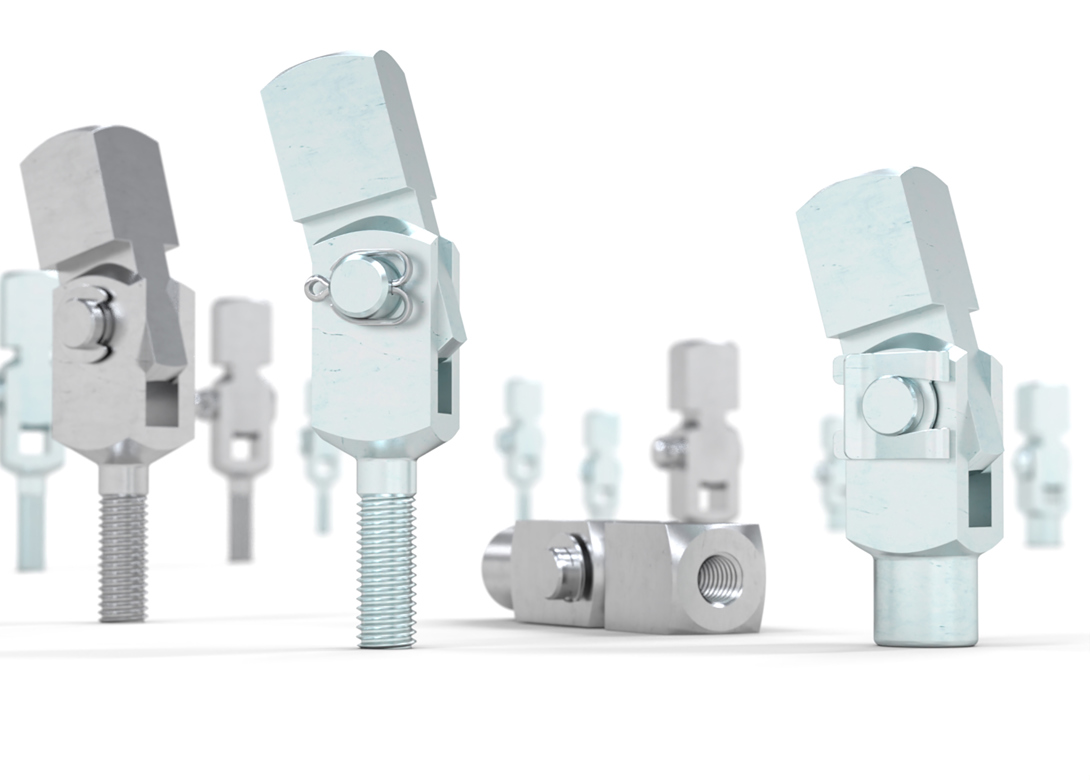

WDS has launched a range of linkages including clevis forks, eyes, pins and clips to suit actuators typically used in machine build. The Leeds-based standard parts and components manufacturer and supplier has created the range for hydraulic, pneumatic and electric powered machine actuation.

As WDS clevis linkages are designed to the DIN and ISO standards, this ensures fit across the widest range of applications. The range is also suited to new machines and retrofit with a design that allows for greater flexibility in alignment. The clevis fork and eye connection enables a margin of movement, which is particularly useful for easily linking two components in hydraulic and pneumatic applications where precise alignment can be challenging to achieve.

The range includes all linkage options in premium stainless steel as well as durable yet cost-effective zinc plated steel. Linkages include female clevis fork end fittings, as well as threaded male clevis fork end fittings, and both fork types are available in M6, M8, M10 and M12. Clevis eyes are available in standard as well as spring bolt options for angled linkage. The range includes retention pins that are secured by a choice of E clip, cotter pin or spring clip.

A new design of safety clip is also offered, offering more secure fastening and easier fitting. Two new safety clips are available, the first in an easy assembly design, which is quicker to fit and remove than standard E clips. The second safety clip variant provides greater resistance to vibration, offering very secure fastening which also prevents rattling, making it well suited for use on high speed machinery. Both clips are constructed from spring steel and are hardened and tempered to provide lasting durability.

In addition to machine actuators, the clevis linkage range can also be integrated with WDS’ range of gas struts as well as use on shaft connections. WDS carries the range with full stock across all clevis linkage components with same-day despatch available to suit demanding OEM production schedules. Large stock also means WDS can fulfil highly competitive pricing across single digit orders and high volume requirements.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.