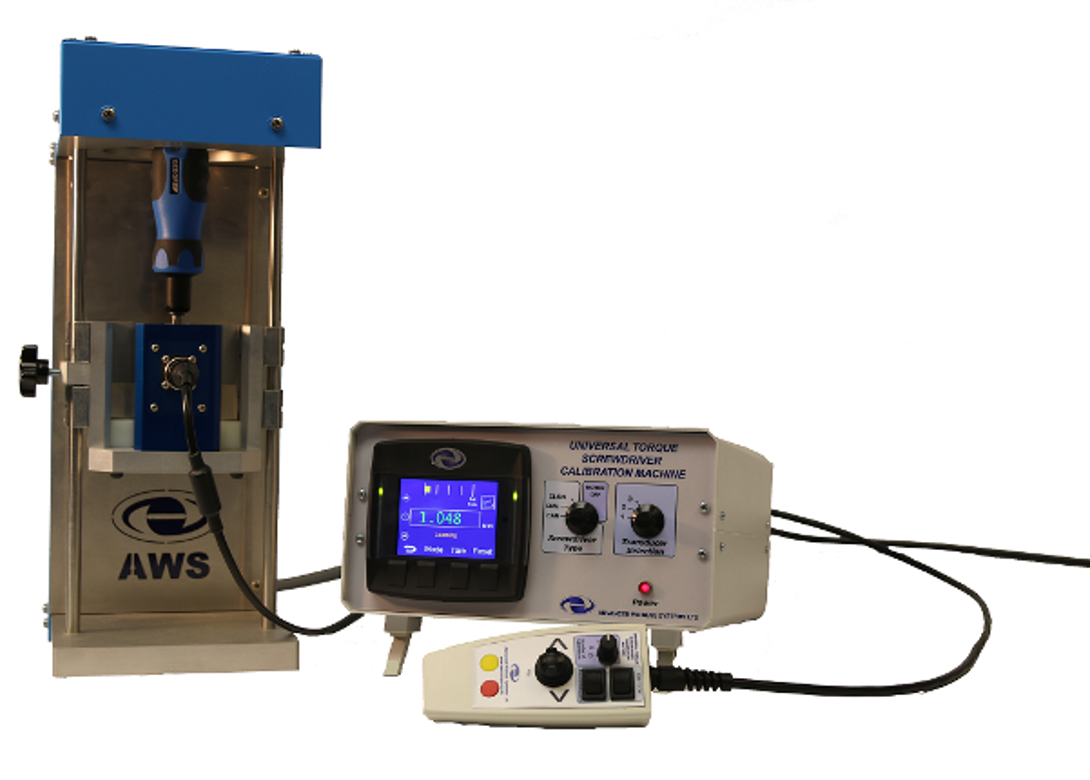

The UTSCM for compliance to ISO 6789:2017 provides an efficient means of calibrating and testing manually operated torque screwdrivers to international or company specific standards and specifications.

The UTSCM applies the torque to the tool via a tooth belt drive connected to a stepper motor and an AWS microcontroller. The larger belt pulley holds an adaptor designed to fit a specific model of screwdriver to minimise the uncertainty of adaptor alignment and ensure the screwdriver is within ±2° of vertical.

The UTSCM can be used with new ADMS Kepler 4 software to speed up completion of the calibration and certification process to ISO 6789:2017, ISO 6789:2003 or type approval for manufacturers.

With the variation in torque screwdriver operation, the UTSCM using a microcontroller, runs through a learning cycle before calibration to record the shape of the torque curve, to ensure the torque is applied at the correct rate to meet the ISO standard. As required by the standard, the number of operations are selectable, capturing each reading consecutively, greatly reducing the time for the calibration and certification process.

Due to the great variation in screwdriver handles, grip adaptors are bespoke designed to fit a specific model. This to minimise the uncertainty of torque screwdriver alignment, ensuring it is within ±2° of vertical alignment, as required by the standard.

Designed to calibrate/test screwdrivers up to 30Nm, the screwdriver also feature an inbuilt microcontroller and display for accurate control of load applied and operation speed.

The microcontroller also ensures the adherence to the minimum target torque approach times, complying with the ISO standard, for the capacity of screwdriver being calibrated.

The screwdriver type can be selected, to be either cam, dial (indicating) or click type. The number of operations run consecutively can be selected, to be either 1, 3, 5 or 10 as required by the standard.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.