Here Dr Bill Eccles of Bolt Science addresses the challenges of tightening multiple bolts in a joint, as well as the effects this can have on the individual preloads within the group – a phenomenon known as elastic interaction.

Most joints consist of several bolts and since these bolts are often not tightened simultaneously; tightening one bolt has an effect on the preload of other previously tightened bolts in the group. Such an effect is called elastic interaction, or alternatively bolt crosstalk.

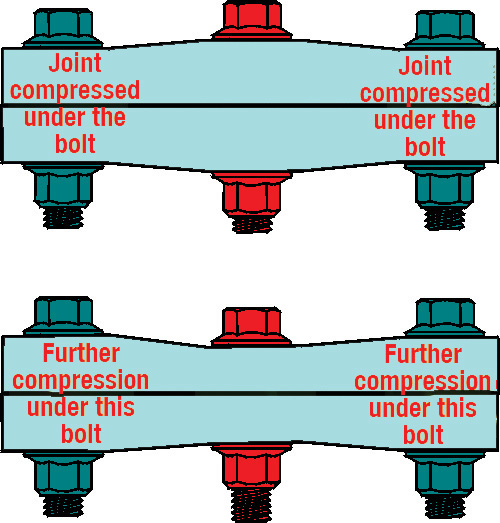

Ensuring that the bolt loading is even is critical in gasketed joints to help minimise possible leakages, but obtaining an even bolt load distribution is not clear cut since the final bolt load usually differs from the initial bolt load. The mechanism that causes this is illustrated in Figure One.

As demonstrated in Figure One, the outer two bolts have been tightened to compress the joint. The middle bolt has also been tightened to compress the joint directly underneath it, an action which has led to further compression of the joint under the two other bolts, thus leading to a loss of preload in these bolts.

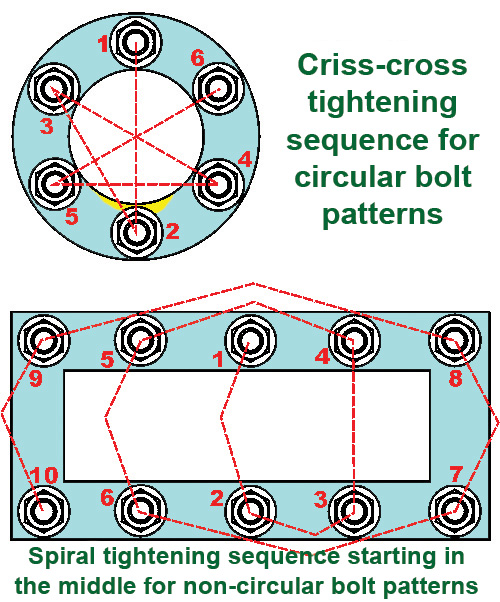

In Figure Two, two classical examples of tightening sequences are shown, one for a rectangular array of bolts and the other, a circular array. Both are sequences that have been shown to result in providing a reasonably uniform bolt load, meaning they will minimise the preload scatter within a joint. On many gasketed joints, and on solid,

non-gasketed joints that are critical, a multiple pass tightening sequence is often used. With such a sequence, each bolt is tightened more than once to help reduce the preload reduction caused by tightening the other bolts in the joint.

Tests have shown that the elastic interaction between bolts in a joint can have a significant effect on the preload (a reported reduction of 35%). The ‘softer’ the joint is – as in a joint with low stiffness – the larger the elastic interaction effect can be. A gasket typically results in a low stiffness joint, so tightening the bolts incrementally, multiple times, is often needed to achieve an even loading.

There are other tightening sequences that have been shown to produce a reasonable uniform bolt loading. For example, work completed in Japan demonstrated that after ensuring the joint surfaces are parallel to each other, going around the bolts in the joint and tightening them several times until no further rotation occurs was shown to provide acceptable results.

FUJIFILM has even manufactured a film that will allow the pressure distribution within a bolted joint to be determined. This can be useful in checking and optimising a tightening sequence. The film is inserted between the plates of the joint and then the joint tightened. The subsequent colour change in the film determines the localised pressure, an effect caused by microcapsules in the material designed to react to various degrees of pressure, releasing their colour forming material at a density that corresponds to the pressure.

If more information is needed on tightening sequences, Dr Bill Eccles recommends the publication ASME PCC-1-2022. This is a standard that provides guidelines for pressure boundary bolted flange joint assembly.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.