By Peter Standring, technical secretary, Industrial Metalforming Technologies

No genuine forward progress can be made without first obtaining a clear understanding of the knowledge required to make it. Getting to the bottom of a problem means just that – because without sound foundations, nothing substantial can be constructed.

For example, chemistry is based on the identification of basic elements, without knowledge of which the world we currently inhabit could not exist. Likewise, physicists believed they had established the smallest possible unit of an ‘element’ when they discovered the atom. Yet, the quantum world of sub-atomic particles has revealed that on a human scale, there are more zeros needed going smaller than required to reach the edge of our expanding universe.

This is why we can never hope to obtain perfection! Of course, peering into a mist like this is simply a recognition of our collective human ignorance but fear not, we can get by quite well by employing the knowledge we do possess. If ‘perfection’ is beyond our grasp, let us change the requirement to ‘fit for purpose’ and from our existing achievements we can certainly obtain that.

Quality

When used in a marketing context, the word ‘quality’ is often a euphemism for ‘hype’. Quality, time, performance, life, etc, all are seeking to use the term to exceed the norm. However, if the norm is ‘fit for purpose’ why do those in the market seek to enhance their product by giving it an unnecessary epithet?

Being commodity products, fasteners do not generally have to attract the eye or become a ‘trend’ item. They need to carry no more than an internationally recognised, acceptable and traceable means of identification. Anything more would simply mean unnecessary embellishment and extra cost. In the world of fasteners ‘quality’ is taken as read and simply implies that the item meets and satisfies all the required standards. However, in an imperfect world, the question then becomes, what level of defects does the purchaser accept?

Attributes

In almost every issue of Fastener + Fixing Magazine, the range of fastener geometries and their apparent complexity seem to increase. This is probably not true as over the years, specialisation, standardisation, and rationalisation, of both the sector and its products have created significant conversion. Notwithstanding, the changes in the various fastener markets and the opening of new ones, plus the continuous challenge to achieve more with less, has undoubtedly made fastener geometry more complex. Special heads requiring special tools – for both security and brand – as well as multi-functional bodies/threads, which include the capabilities of both cutting and fastening, are currently available. Dual purpose applications requiring different material properties, which can only be achieved in a single product by a combination of dissimilar materials. These all increase the number of attributes in the part and with them, the need for assessment.

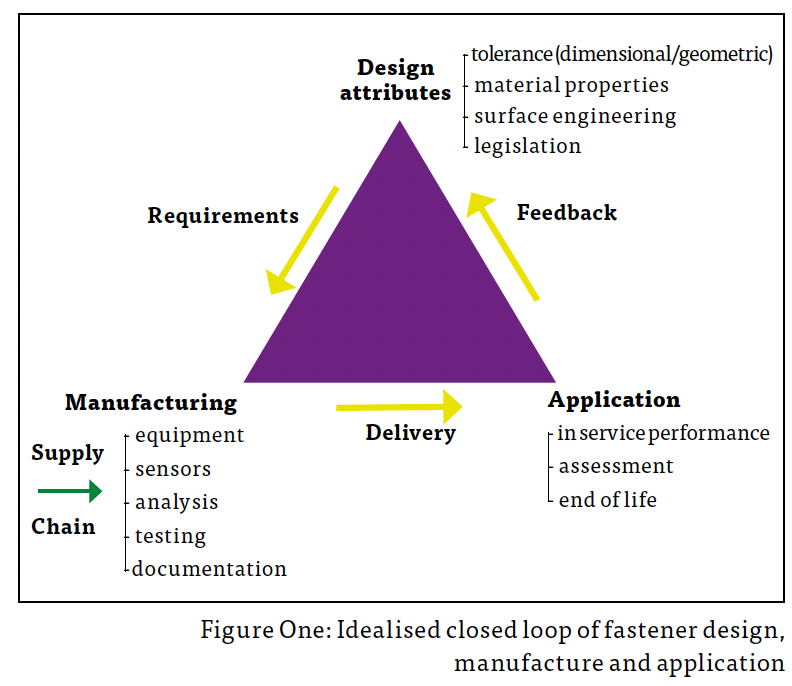

In every fastener, the attributes associated with it include tolerances – dimensional (length, etc), geometric (roundness, etc), material (properties), as well as surface finishing (coatings). As shown in Figure One, depending on the ‘standards’ to be met, these will also include destructive/non-destructive testing of samples per batch; full documentation of input material; plus all fully audited processing of the parts (equipment used/calibration, etc), heat treatment and inspection. Within the EU, and possibly elsewhere, this will also include information required for the Carbon Border Adjustment Mechanism (CBAM) regulation.

Dimensional attributes

In the production of threaded fasteners from rod or wire, it is relatively easy, using off the shelf equipment, to obtain both dimensional and geometric measurements once a part has been made. Although this may be a necessary part of a batch inspection process, on its own, it is wholly inappropriate for mass manufacture. Clearly, off the machine sampling is a post-process operation – therefore any part found to be out of specification will need the process to be stopped and checks made to determine, how, when and why the process went out of control.

This is why in-process sensors, both recording and control, are an absolute essential to gain knowledge over the process route. All component dimensions have both an upper and lower limit – the specified tolerance of the designed feature. The wider this tolerance, the less accurate/expensive the equipment needed to make the part.

As a tool, that is making a part, wears the part dimension approaches a limit and the sensor informs the machine setter of the changing situation. If left unattended, the system will automatically switch off once the tolerance (action) limit is reached. Such information has been listed for many years in the International Tolerance (IT) Grades Table Chart ISO 286-1. IT grades 01 – 18 underline the measuring tools, fits required and manufacturing methods available. IT 01 represents the tightest tolerance grade.

When a machine is initially set-up it is generally arranged to make the part to the particular tolerance level (upper or lower), which will enable tool wear to change the dimension within the tolerance band. A hole will get smaller and a cylinder larger as a manufacturing tool wears. Continuously recording these dimensions sequentially and then visual plotting the output will indicate that the process is under control. To ensure the upper and lower tolerance limits are not breached, other tolerance bounds are produced to lie inside them. These are termed ‘warning limits’. The statistical data obtained from such systems enable statistical process control (SPC) to be obtained, which in turn provides automatic control over the manufacturing process. Also, it provides direct online information of the ‘trends’ in performance of the equipment, materials, settings, etc.

Geometric attributes

Dimensional measurements are basically two dimensional. Geometric attributes on the other hand refer to a component’s surface features. These include cylindricity (roundness), flatness, parallelism (between two opposing faces), squareness (between adjacent faces), eccentricity (radial departure from a common axis), etc. Geometric Dimensioning and Tolerancing (GD&T) is significantly more complex than dimensional tolerancing and whilst there exist a number of standards, such as ASME and ISO, there are differences between them.

The whole concept is based on the establishment of a theoretical datum from which all measurements are determined. This can be a surface or a point, plane or an axis, which provides the reference on which everything else is based. For example, in the case of flatness, it is assumed that a second ‘theoretical’ surface exists, displaced away from the ‘datum’, by the distance of the tolerance boundary. For a component to be deemed ‘within tolerance’, its surface must lie between these two imaginary planes.

Of course, it is perfectly possible that the datum surface may lie between the tolerance limits. This is the case where surface roughness can be determined using the technique of Centre Line Average (CLA). Here, the measuring stylus is drawn across a surface and the resulting distribution of recorded ‘peaks and valleys’ used to determine the CLA value of surface roughness. Other visual and statistical methods for determining surface roughness also exist.

It should always be recognised by design engineers that whilst geometric attributes may be key to the functionality of a part/assembly, their careless, or misunderstood use can cause serious manufacturing problems and cost to the fastener manufacturer. For example, if a sophisticated heat treatment regime marginally changed the helix angle of a threaded component – giving rise to varying thickness (distributed mass) – would that matter if its ‘fitness for purpose’ was unaffected. It might, if the person who designed the part included an unnecessary geometric tolerance, which was now exceeded.

Material attributes

Existing fastener specifications relating to material requirements and their audit trail are well established – that is until a Regulatory Body decides on improvements. However, where more multifunctional, multi material, multi design features are incorporated to obtain more for less, the need for performance testing increases. Simple tensile, torque and hardness testing are of course necessary but if the fastener is to be used in hostile environments, under many different loading conditions and possibly in maintenance excluded areas until end of life, then discerning customers will require suitable guarantees of satisfaction.

Accelerated testing is well established as a practical tool for a wide range of products, but in a fast moving world of solving someone else’s problems, as they emerge, is this an extra burden that fastener manufacturers should reasonably be expected to shoulder?

Surface finish attributes

As fastener specialisation increases, the desire to do more with less falls increasingly on the fastener/assembly interface. It is also a fact of life that all fastener users, if given a choice of having to use a fastener or not use a fastener, would choose the latter. Fortunately, despite the development of 3D printing and adhesives, for both the fastener manufacturer and distributors, the need for fasteners is unlikely to change any time soon.

However, the requirement for fasteners to meet the demands of new and emerging market sectors has, in less than one working lifetime, transitioned amazingly from pre-electronic ironmongery, through space travel to climate change.

Regarding climate change, two camps exist, those who want to ensure what we are doing to the planet is controllable, and others who don’t. In reality, it’s the folks who put up the signs who determine the speed limit not drivers. The signs on climate change have been put up and are continuously being added to. In short, if you want your goods to flow from here to there, you too must abide by them.

End of life, recyclability, ease/cost of disposal are all natural targets for the legislators to enhance the quality of life of the only place in this universe where people can live.

Clever, multifunctional designs, incorporating multifunctional materials, may offer OEMs great opportunities for lightweighting, extreme service conditions, and reduced assembly inventories, but they may also provide easy targets for those seeking to improve the desired quality of life for all. This is not just a consideration relating to the product, but it also involves all aspects of fastener manufacture – including its supply chain partners.

Conclusion

On ancient maps showing strange and often uncharted lands, it was not uncommon to find illustrations of two headed people and inscriptions stating: ‘Here be dragons’.

Given the rapidly changing world in which we live today, it might not be too long before the fear of global pestilence, flooding, drought and air quality could produce a world not dissimilar to us than those found on ancient maps. The future is simply unknown territory and without a map, who can say what strange things might lurk there.

The ubiquitous nature of fasteners, and the fact that they were probably mankind’s first technical achievement, places them at the leading edge of our voyage of discovery into the future. For this reason, the development of fasteners and the reasons why they are the way they are will be known first by those who make and use them.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.