Historically, solvent-based adhesives have been a popular choice for many production facilities, however in recent years there has been an increase in the number of manufacturers who have switched to solvent-free bonding. Chemique Adhesives pioneers solvent-free bonding to utilise a safer adhesive solution.

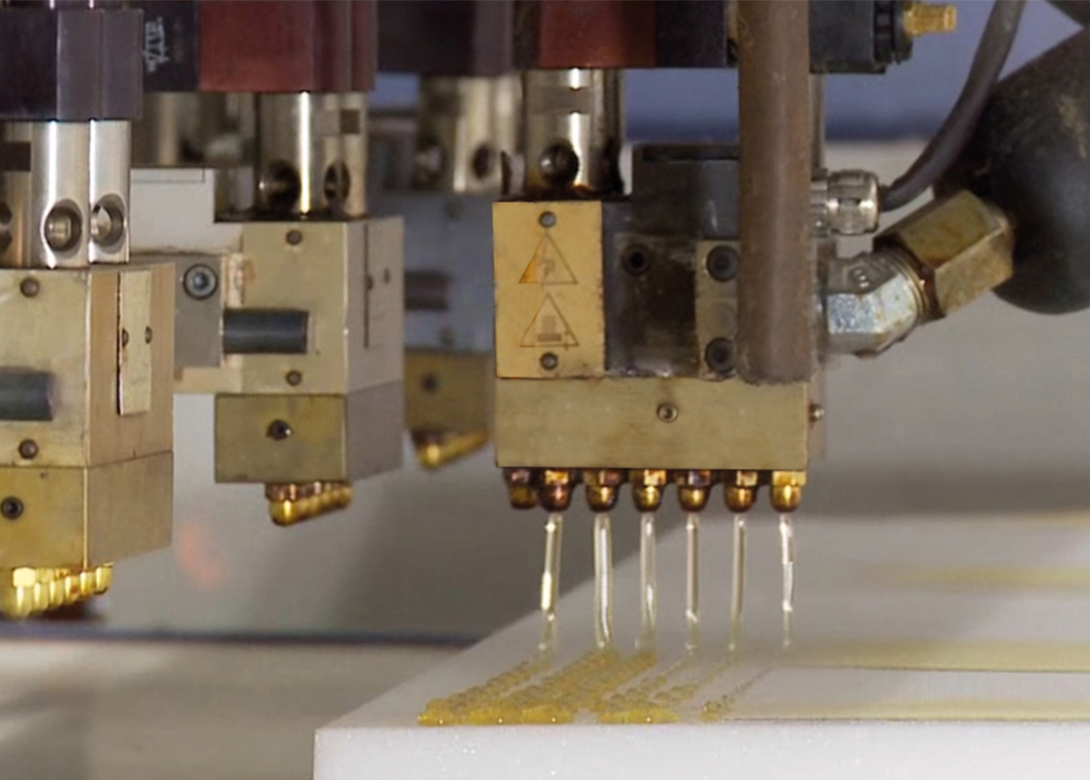

Hot melts are a type of thermoplastic adhesive that are generally 100% solid and are brought to a liquid state by applying heat. Hot melt pillows are melted using a hot melt tank / hopper and are then applied to a substrate in its liquid state. As the hot melt cools to room temperature, it solidifies, and a strong bond is created.

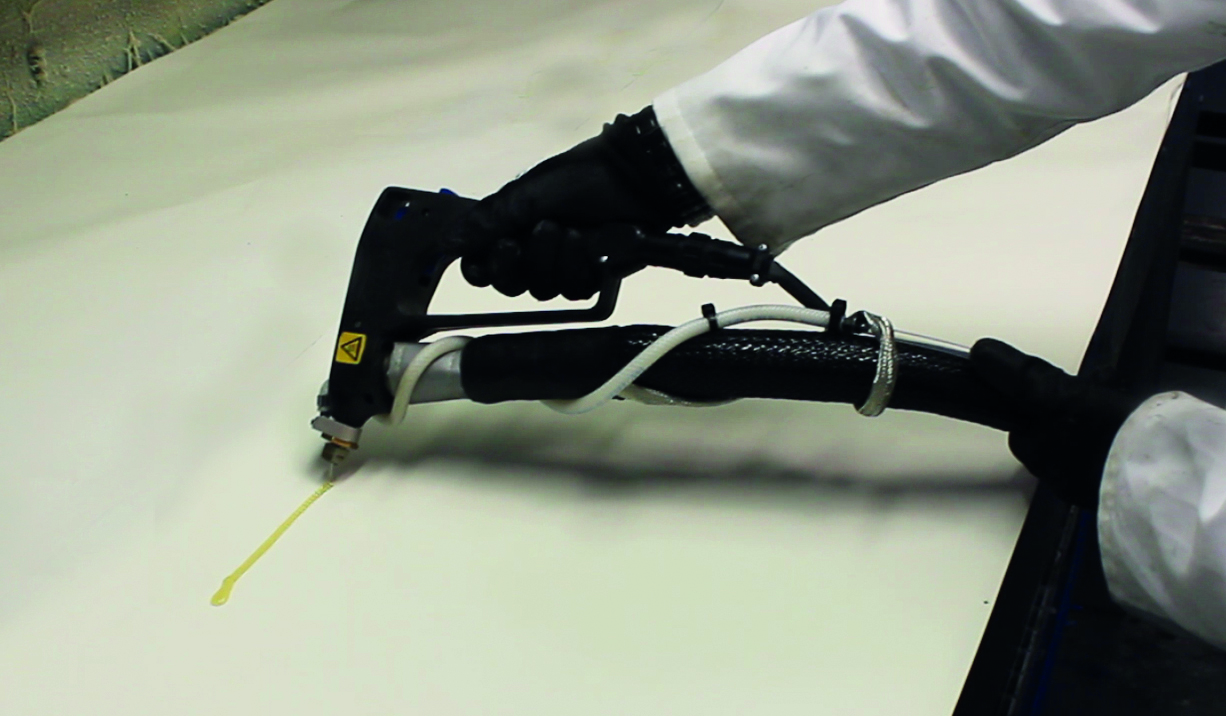

Stuart Francis, managing director of Chemique Adhesives comments: “For over 30 years we have made progressive steps towards eliminating hazardous solvents from the workplace. Our hot melts have been designed for both automatic and manual systems so whether you are automatically applying the adhesive in a bead or a swirl pattern or indeed hand beading or spraying, then we have a grade to suit.”

Hot melt adhesives are a much more stable option than many solvented adhesives and are easy to store, as they do not require any special conditions other than the avoidance of extreme temperatures.

The Protak range of hot melts offer a variety of technically advanced adhesives based on EVA, PUR and polyolefin resins. These products have been specially formulated to provide a high adhesive performance in a variety of applications including edgebanding, foam bonding, mattress manufacturing, packaging, panel lamination, as well as product assembly.

Hot melt adhesives have many advantages as they contain no solvent emissions, are high strength, offer excellent heat resistance and are designed for a variety of substrates with open and set times available to suit the necessary application. The experienced technical sales and service team at Chemique Adhesives can provide innovative solutions by conducting a thorough review of a company’s existing bonding process and suggesting a safer type of adhesive.

On-site or laboratory testing is also carried out to prove that the recommended adhesive will not only provide a less hazardous alternative but can also offer cost savings, improved efficiency, and increased output. As well as this, Chemique Adhesives can also install and regularly service all required equipment for added peace of mind.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.