Here SMT Srl, the independent testing laboratory and mechanical workshop – with over 30 years of experience in mechanical, chemical, metallographic and mechanical fracture testing, looks at the EN ISO 898-1 standard and what it means for property Class 8.8.

The EN ISO 898-1 standard for property Class 8.8 provides some mechanical characteristics to be obtained and leaves space for choice regarding chemical analysis.

In fact, it provides for the possibility of using three generic types of steel:

Carbon steel with C = 0.25 ÷ 0.55, S and P less than 0.025% and B less than 0.003%.

Carbon steel containing boron or manganese or chromium, with limitations on the analysis equal to that of carbon steel but with C = 0.15 ÷ 0.40%.

Alloy steel, equal to that of carbon steel but with C = 0.20 ÷ 0.55 and with the obligation that the steel must contain at least one of these elements: Cr (0.30% min), Ni (0.30% min), Mo (0.20% min), V (0.10% min).

In all three cases, the steel must be quenched and tempered. As often happens in the industrial world, people are inclined to make the most advantageous economic choice and therefore are inclined to choose carbon steel that has a lower cost than alloyed steel, but is this choice correct?

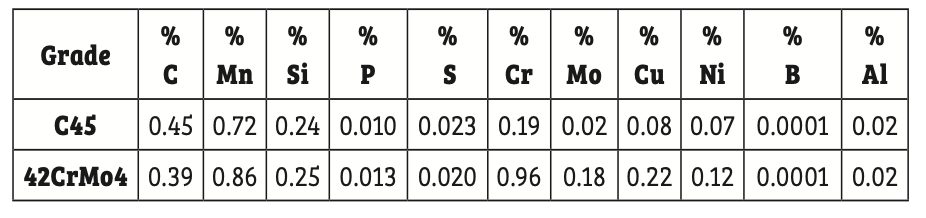

We took two threaded bars approximately 14.4mm, one in C45 and the other in 42CrMo4, with each having the following chemical analyses:

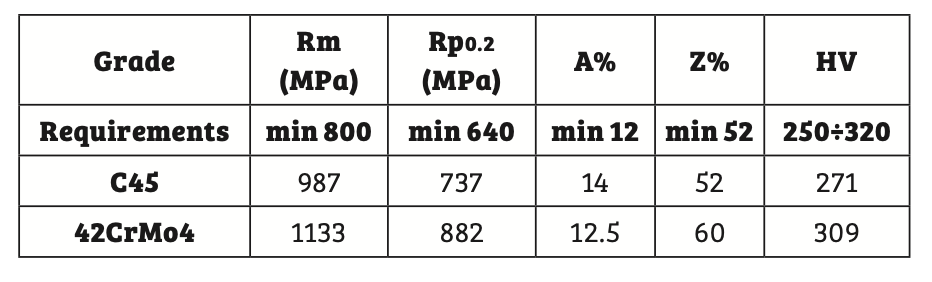

We submitted the two threaded bars to both tensile and hardness tests. The results obtained are visible below, where the values required for property Class 8.8 have also been entered:

The mechanical characteristics were met by both grades of steel. However, does that mean everything required by the EN ISO 898-1 standard has been satisfied? In Table Two of this standard, there is ‘note f’ next to property Class 8.8 (also present for property Classes 9.8, 10.9 and 12.9). This note says: “For the materials of these property class, there shall be a sufficient hardenability to ensure a structure consisting of approximately 90% martensite in the core of threaded sections for the fasteners in the” as-hardened “condition before tempering”.

Therefore, to find out if the threaded bars comply with property Class 8.8 it is also necessary to check their structure. We therefore longitudinal-sectioned the two threaded bars and checked the core structure.

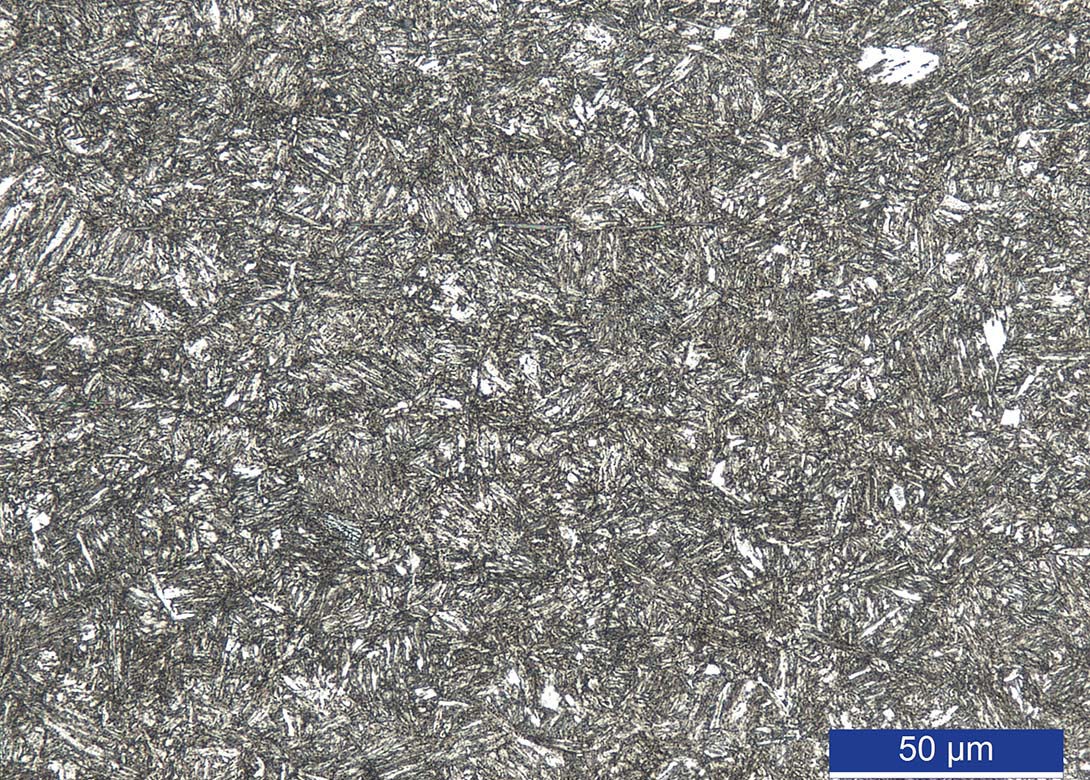

The core structure of the 42CrMo4 threaded bar is made of 100% tempered martensite, a sign that after quenching the structure was correctly 100% martensite (Picture One).

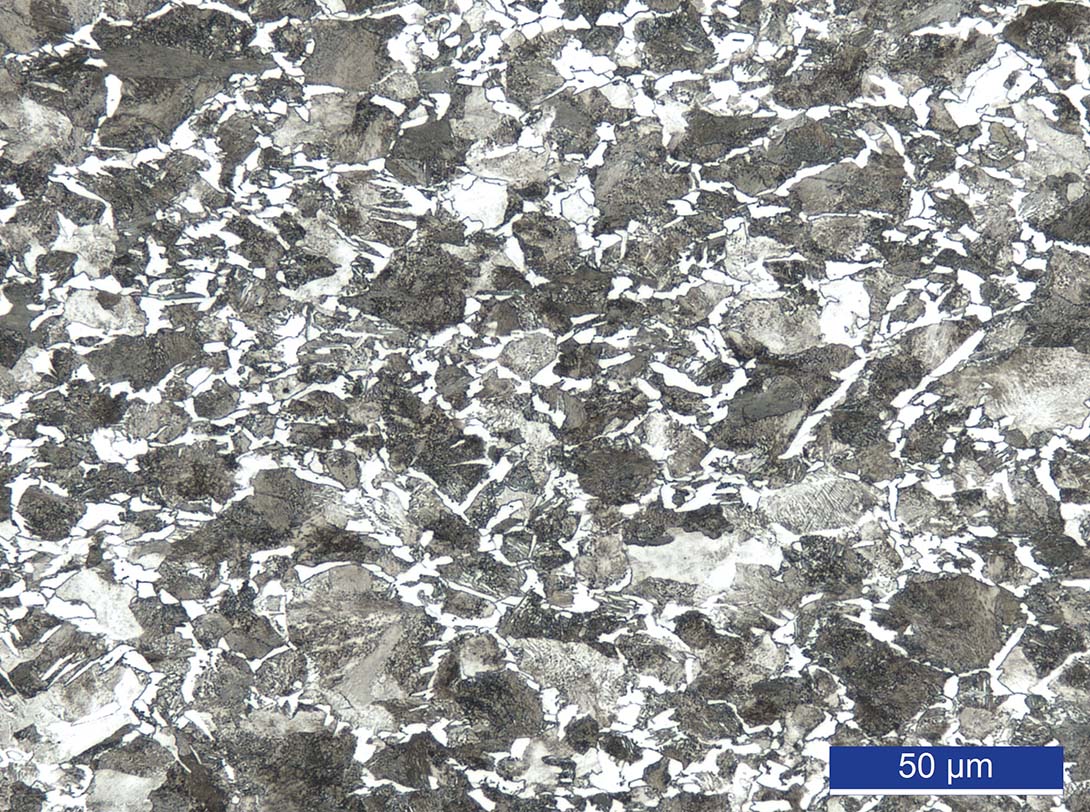

The structure of the C45 threaded bar instead made of reticular ferrite and perlite, incompatible with a 90% martensite structure after quenching (Picture Two).

From this it can be deduced that the threaded bar in C45 does not comply with the standard and should not be used. This demonstrates that mechanical tests are not sufficient to verify that a threaded bar is compliant or not. It is also necessary to carry out a micrograph.

Some might argue that the standard is wrong because it allows the use of carbon steel, which does not allow the user to obtain the required structure. However, this is not the case and in the next issue of Fastener + Fixing Magazine SMT will explain why.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.