The manufacture of pharmaceutical and medical products demands precision, perfect finish, durability and reliability, standardisation and customisation. It’s hard to imagine a field where there is such a consistent need for unerring performance.

Production of springs for this elite industry sector involves detail consideration of characteristics such as material parameters, finished spring feel, location within equipment, e.g. exposure to biological materials, or not.

Lee Spring supplies springs across a number of different areas such as:

- Springs for pharmaceutical delivery systems such as syringes, check valves, pill dispensers, pill counters, fluid control, intravenous valve controls, pharmacy automation, automated drug management, liquid and dry powder inhalation devices.

- Springs for medical devices including surgical tools and instruments, staple guns, orthopaedic tools, suction lines, catheter valves, peristaltic pumps, anaesthetic infusion, sterilisation valves, fluid control valves, sterilisation equipment.

- Springs for related devices such as shunt valves, wheelchairs, medical instrumentation, diagnostic devices, centrifuges, testing, monitors and inductors, booms, lifts, accessories and air flow management systems.

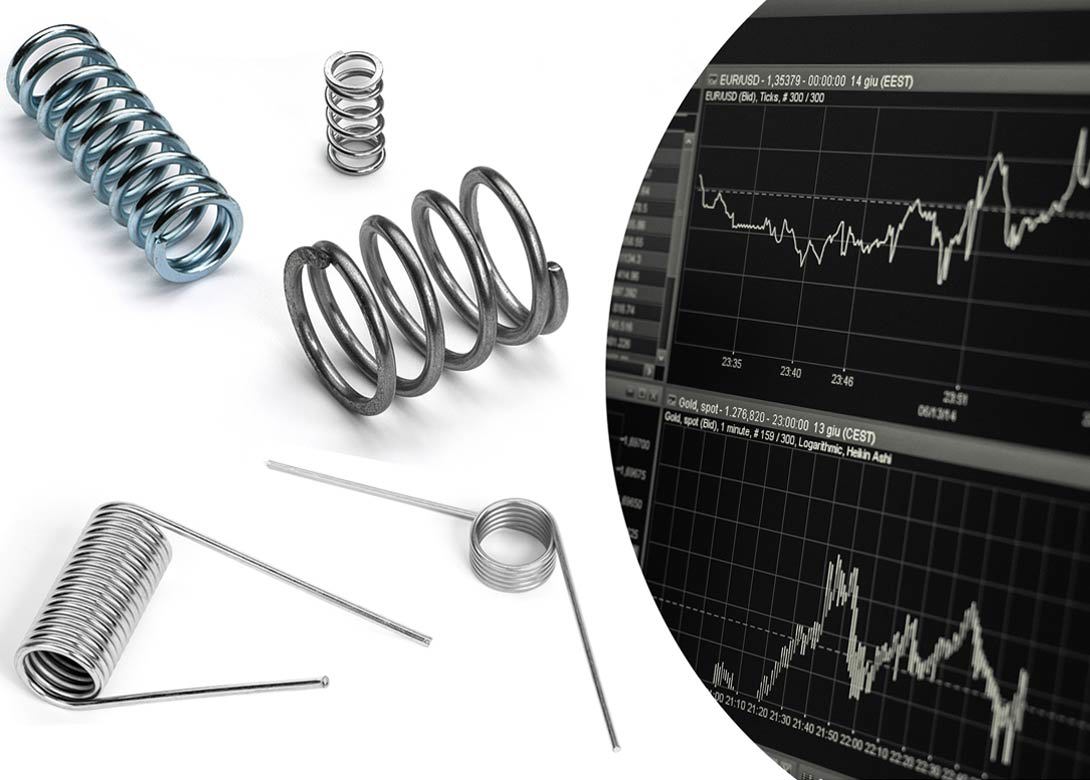

Stock for same day despatch includes such unique items as type 316 stainless steel Lite Pressure™ compression springs and silver coated beryllium copper springs, as well as wave springs, compression springs, extension springs, torsion springs, constant force springs, Belleville washers and more. All stock items are RoHS and REACH compliant.

Materials used in this demanding sector include Stainless Steel 316 and 17-7; Elgiloy™; Inconel 600, 718 and x750; Phosphor Bronze; Beryllium Copper; Hastelloy®, and Plastic Composites.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.