By Barnaby Redwood, team manager at Ayming.

Nothing lasts forever. Everything we make – from phone handset to buildings – has a finite design life. And that can be cut short by wear and tear.

So when cracks appear in a tablet computer screen or a concrete bridge deck, the only options are to repair or to replace. After all, self-regenerating machines and robots belong to the realms of fantasy.

However, in the field of materials science, fiction is fast becoming fact. Scientists believe we’re on the cusp of a smart materials revolution.

Man-made materials are already taking on the self-healing capabilities of living things. Specially formulated plastics, paints and concrete are pointing the way to a brave new world of smart materials for construction and many manufactured goods.

There are four main types of self-healing material:

• Embedded microcapsules contain ‘healing agents’ that are automatically released by an impact or cracking in the material.

• An ultra-fine internal ‘vascular’ circulation system passes adhesives or other healing agents to the point of any damage.

• Shape-memory materials that when heated, revert to their original form.

• Reversible polymers, such as thermoplastics, in which the polymers flow and bond, again in response to heat or light energy.

Self-healing rubber, plastics and paint have already been developed. Carmaker Nissan launched its Scratch Shield paint technology on some up-market models in 2005. The chemical structure of the finish, which has a polyrotaxane top layer, reacts to fine scratches, restoring its original state. Depending on the depth and ambient temperature, scratches take between an hour and a week to heal.

Now thermoplastic urethane is being marketed in the UK as a ‘paint protection film’ for car paintwork. Scratches in this wrap – likened to thick cling-film – disappear as the material reverts to its original shape.

Similarly, LG’s G Flex 2 – a flexible mobile with a curved screen – shipped in 2015 with a polymer-coated casing. Superficial scratches, such as the abrasions left from keys, vanish in seconds.

A mobile phone or tablet screen that could recover from crack-inducing mishaps would be even better. Self-repairing ‘glass’ may be on its way – thanks to an accidental discovery by some Japanese researchers last year. A graduate-school student preparing a glue material (polyether-thioureas) noticed that the cut edges of the polymer bonded together when compressed by hand. University of Tokyo scientists hailed this as the first hard polymer material that heals without being heated to high temperatures.

NASA has designed a polymer that when penetrated by a bullet – or high-speed debris in space – will self-seal the hole, which could protect satellites and aircraft fuselage from catastrophe. The temperature from the impact is enough to make the polymer to flow and bond.

A Bristol University team showed in 2015 how fine cracking in the carbon-fibre reinforced wings of an aircraft could be reversed. They added tiny hollow microspheres – which look like powder to the human eye – to the carbon material. These break on impact releasing a liquid healing agent that rapidly hardens within the cracks. This technology, predicted to be available in 5-10 years, could be used to effect repairs in other carbon fibre structures from golf clubs and bicycles to wind turbines.

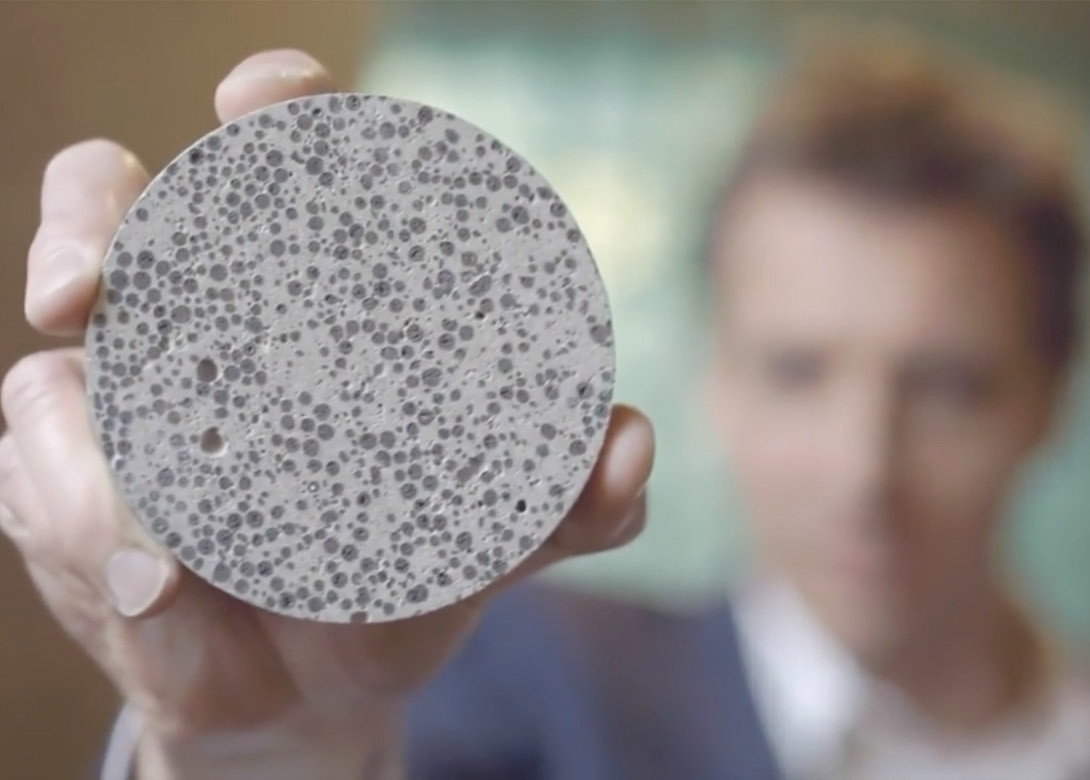

But the nearest and most universally useful structural smart material on the horizon may well be bio-concrete. Microcapsules containing bacteria and an organic nutrient (calcium lactate) are added to the concrete mix. When cracking occurs and water penetrates, it activates the bacteria, which feed and secrete limestone (calcite), filling the cracks. The process takes up to three weeks.

As the bacteria can lie dormant for up to 200 years, the lifespan of new roads, bridges, tunnels and buildings constructed from bio-concrete could be extended significantly.

Several trials began in 2015. Using this technology, microbiologists at Delft University have gone on to develop a liquid spray for treating existing structures.

In the UK, the Resilient Materials 4 Life project is trialling bio-concrete along with the other main self-healing techniques, including shape-memory polymers and vascular networks. In September 2015 Costain constructed five sections of concrete retaining wall embedded with these self-healing systems on the A465 Heads of the Valleys road upgrade in Wales.

Researchers from the universities of Cardiff, Cambridge, Bath and Bradford are monitoring their post-healing performance. Last year the Government backed the project with a £4.8 million grant from the Engineering and Physical Sciences Research Council. Costain and other industrial partners have invested £2 million.

The project’s results so far are said to be highly promising. EPSRC Chief Executive Professor Philip Nelson says: “Resilient Materials 4 Life has the potential to revolutionise the way our infrastructure copes with longterm wear and tear and reduce costs significantly.”

In the UK alone, £40-50 billion is spent each year on repair and maintenance of structures, mostly made from concrete. This is roughly equivalent to 35% of total construction output.

Some of the early mass market applications of self-healing substances may be cosmetic rather than structural – paints and coatings that shrug off hairline cracks and offer higher resistance to weather and wear.

But where crack reversing screens for mobile phones may lead, developers of high rise buildings with glass facades are likely to follow. The automotive, construction and aerospace industries are expected to see significant applications of smart materials.

Adoption, of course, will depend on the costs and benefits. But in a warming world of depleting resources, smart materials that are more durable and thus sustainable could prove invaluable. Concrete production alone contributes 5-7% of carbon emissions.

Defiantly shiny car bodies and phone cases only scratch the surface of the potential that self-healing materials have to transform the built environment and just about every industry.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.