Robnor ResinLab, leading formulator of epoxy and polyurethane resin systems, is pleased to announce the launch of a brand-new development material, PX19-GE3259-03. This epoxy foam offers good adhesion to a wide variety of substrates.

The two-component epoxy system is particularly suitable for void-filling applications and has good compressive strength for backfilling of parts. It can also be used in the casting of buoyant materials,or as a machinable epoxy foam for model making.

The lightweight foam has a low density of approximately 0.25g/cm, which means only a relatively small amount of material is required to fill a large volume. This reduces material waste and makes PX19-GE3259-03 a cost-effective choice.

Furthermore, PX19-GE3259-03 from Robnor ResinLab offers good thermal performance post-cure and has an operating temperature of up to 150°c.

With a low viscosity of just 3000 (when mixed), this new material is very easy to process and work with.The system’s slow foaming reaction generates low pressure during expansion and has a cure time of 24 hours at room temperature.

Additionally, PX19-GE3259-03 is also available as a three-component system. This allows users to adjust the foam density to suit their specific application requirements.

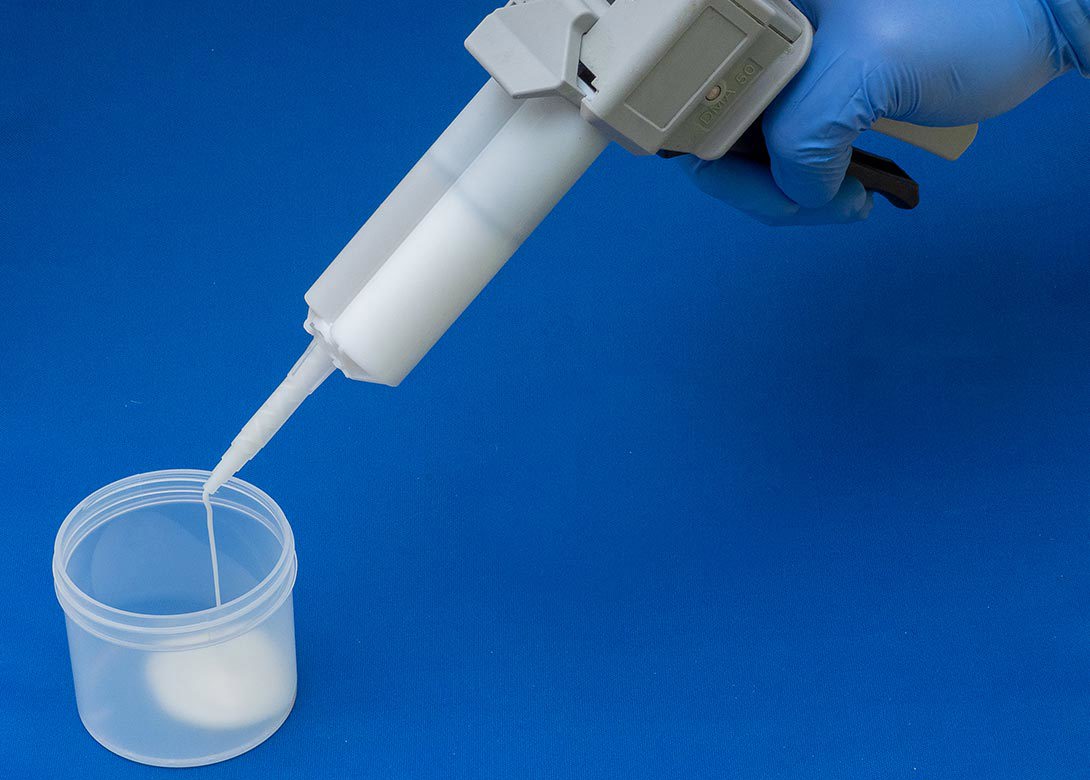

Robnor ResinLab PX19-GE3259-03 is RoHS compliant and can be purchased in bulk, twin-packs or 2:1 ratio cartridges.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.