Here Bill Eccles, of Bolt Science, focuses on the reduced loadability of DIN nuts when compared to ISO nuts and how important it is to check nut markings to ensure the products are the correct property class.

Some years ago, on a Bolt Science training course given to largely design engineers at a major manufacturer, they spoke about a thread stripping issue they had on one application – the nuts were stripping, and they didn’t know why.

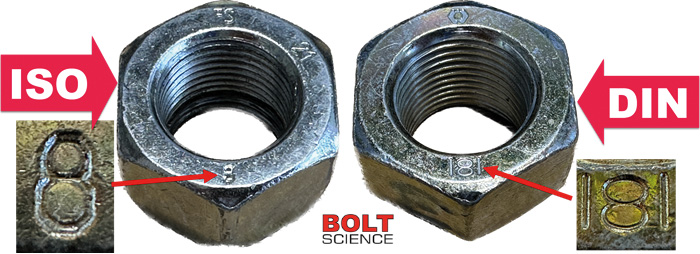

Looking at the nuts which had a |8| marking on them, they had assumed that they were property Class 8 to the relevant ISO standard (ISO 898 Part 2). They thought that the vertical bars at either side of the 8 was just decorative and of no significance. In fact, they are essentially a separate property class, property class |8| to a withdrawn DIN standard. Such nuts have what is referred to as reduced loadability, the nut’s proof load is lower than that of an ISO nut. The reduced strength of the DIN nut was a likely cause of the thread stripping issue that they were experiencing.

Looking at the nuts which had a |8| marking on them, they had assumed that they were property Class 8 to the relevant ISO standard (ISO 898 Part 2). They thought that the vertical bars at either side of the 8 was just decorative and of no significance. In fact, they are essentially a separate property class, property class |8| to a withdrawn DIN standard. Such nuts have what is referred to as reduced loadability, the nut’s proof load is lower than that of an ISO nut. The reduced strength of the DIN nut was a likely cause of the thread stripping issue that they were experiencing.

Many of the modern fastener ISO standards were developed from original DIN standards, with the relevant ISO standard subsequently superseding the DIN standard. Effectively, the DIN standard becomes frozen at its last update. For example, August 2023 celebrated the 40th anniversary of the last update of a standard that is still used today in the manufacture of millions of nuts. In my experience most engineers are unaware of the reduced loadability of DIN nuts when compared with nuts manufactured to the latest ISO standard. That is, they are unaware that they are weaker and more prone to thread stripping.

A relevant modern standard for nuts is ISO 4032, this provides details of the dimensions of the nuts and refers to the standard ISO 898 Part 2 for the mechanical property requirements. A property Class 8 nut, as shown in the image below, has defined specific strength properties. A proof load is how much load a nut can sustain on the threads without failing, this is specified in the ISO standard. For example, the proof load of an M12 property Class 8 nut is 74,200N. The latest issue of the ISO 898-2 standard (2022) increased the proof load of some of the larger thread sizes to reduce the risk from thread stripping. This further increases the disparity between DIN and ISO requirements.

A historic DIN standard for nuts is DIN 934, like the ISO standard this standard defines the nut dimensions and refers to another standard, DIN 267 Part 4, for the nut’s required mechanical properties. To differentiate from an ISO property class, such nuts have bars at either side of the property class marking, such as |8| as shown in the image below. In this DIN standard, an M12 property class |8| nut has a specified proof load of 67,000N. Significantly less than that of an ISO nut. The reduced proof load requirement is also the case for other thread sizes. The term used in standards for such reduced strength characteristics is reduced loadability. Both the DIN 934 and DIN 267 Part 4 standards are withdrawn and no longer updated. The rub is that it is often stated by fastener suppliers that they are equivalent to the ISO standard; they are not.

If a bolt is over-tightened, for whatever reason, it is desirable that the bolt should fail by tensile fracture rather than failure occur as a result of the nut or bolt thread stripping. If the bolt breaks on tightening, it is obvious that a replacement is required. Thread stripping tends to be gradual in nature. If the thread stripping mode can occur, assemblies may enter into service which are partially failed, this may have disastrous consequences. Hence, the potential of thread

stripping of both the internal and external threads must be avoided if a reliable design is to be achieved. When specifying nuts and bolts it must always be ensured that the appropriate grade of nut is matched to the bolt grade.

For example, if a property Class 8.8 bolt is to be used, a property Class 8 nut, or better, should be used with it. The proof load requirement is the means by which to ensure that the nut has sufficient strength. The specified ultimate tensile load requirement for an M12 property Class 8.8 bolt is 67,400N, which is higher than the DIN nut proof load of 67,000N but less than that of an ISO nut of 74,200N.

In most instances, since the bolt is tightened to loads well below the nut’s proof load, the DIN nuts perform satisfactorily, but not always. Thread stripping is more likely with a DIN nut than with an equivalent ISO nut. This is not just of academic interest; thread stripping failures and accidents have occurred as a result of DIN nuts being used rather than the appropriate ISO nuts.

The last issue of the DIN 267 Part 4 standard was August 1983, 40 years ago. The standard consists of 8 pages compared to 29 pages in the latest (2022) ISO standard (there are many other differences between the standards, just the strength aspect is being highlighted here). The sentence at the top of DIN 267 Part 4 standard is worth repeating: ‘Property classes as defined in DIN ISO 898 Part 2 shall be used for new designs’. There are lots of nuts marked |8|, |10| and |12| that are on designs that are less than 40 years old. Most engineers, in my experience, are unaware of the reduced loadability of DIN nuts. If they were aware, most would likely opt for the stronger ISO nut.

There are other differences between the ISO and DIN nut standards. For example, both the height of the nut and the width across flats dimension can be different. One reason why withdrawn DIN standards are continued to be used on existing designs is that there is a difference in the across flats dimension on certain sizes between DIN and ISO standards. This is true for M10, M12 and M14 nuts, with DIN nuts having a 1mm greater width than the equivalent sized ISO nut and a 2mm difference for M22 nuts.

Bolts and nuts are proof load tested independently. This allows different manufacturers to make nuts and bolts and allows separate checks to be completed, yet for the nut/bolt assembly combination to function as intended when made to matching standards. For example, ISO 898-1 for bolts and ISO 898-2 for nuts. Nuts are proof load tested using a hardened steel threaded mandrel. This effectively strengthens the nut so that when used with a bolt, thread bending, and nut dilation effects, can reduce the thread stripping load. Some suppliers state that their DIN nuts are proof load tested to ISO requirements. A DIN nut is slightly thinner than an equivalent ISO nut and so results in an increase in the shear stress on the bolt thread that can reduce the stripping strength.

I’ve asked engineers why they are using DIN nuts instead of ISO nuts; the conversation tends to go along the lines that they are available now whereas we have to wait for ISO nuts, and we’ve been told that they are equivalent. Ask the fastener supplier and they say, it is the customer, they want DIN nuts, and we give them what they want. Is the use of a standard that is 40 years old, that was long ago superseded by an ISO standard, be regarded as ‘state of the art’, especially considering their reduced strength? This is more than just an academic question when considered in the light of the latest requirements of the Machinery Directive.

Progress often consists of many small steps, small developments that result in safer and more reliable products. A great deal of effort goes into the continued development of ISO standards. The persistence in the use of withdrawn DIN fasteners on new designs freezes progress in fastener standardisation.

Last words: Check your nut markings, are they what you expect them to be?

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.