NSK's ground ball screws, linear roller guides and super precision ball bearings are helping Italian-based IMSA to consolidate its position in the field of specialised deep hole drilling machines - particularly popular for mould making applications in the automotive sector.

Deep hole drilling is a complex machining operation due to the absolute precision and productivity required by today's market, particularly in the automotive mould making industry. The moulds used for the manufacture of medium and large sized plastic components require deep hole drilling to create long and precise cooling ducts, some measuring up to 1,500mm and beyond.

One of IMSA’s most recent innovations is its rotary tilting table, which allows the machining of moulds in five axes using just one clamping position, further reducing manufacturing time. MF1000-3T EVO, a deep hole drilling machine for small to medium automotive moulds up to 2.5 tonnes in weight, is the first model to be equipped with this solution.

Colombo explains: "For this specific application we created a single head machine with one HSK63A electro spindle (200Nm), combined with three deep hole drilling heads featuring automatic head change and an 80 position automatic tool changer. In addition, the MF1000-3T EVO is supported by an automation system of our own design for the two station pallet changer, that is also expandable to six, which allows the customer to carry out complete machining operations of considerable complexity with minimum downtime and long unmanned cycles.”

“Our partners have always played a fundamental role in all of the technological innovations that distinguish our company,” says Marco Colombo, head of technical department at IMSA Srl. “In order to put our design ideas into practice, we use top quality components that can guarantee the best performance and reliability over time. For example, NSK has always been our point of reference in motion control throughout the evolution of our machines. The availability of optimal quality NSK bearings, ball screws and linear guides has allowed us to build the highest performance machines in our sector.”

“Our partners have always played a fundamental role in all of the technological innovations that distinguish our company,” says Marco Colombo, head of technical department at IMSA Srl. “In order to put our design ideas into practice, we use top quality components that can guarantee the best performance and reliability over time. For example, NSK has always been our point of reference in motion control throughout the evolution of our machines. The availability of optimal quality NSK bearings, ball screws and linear guides has allowed us to build the highest performance machines in our sector.”

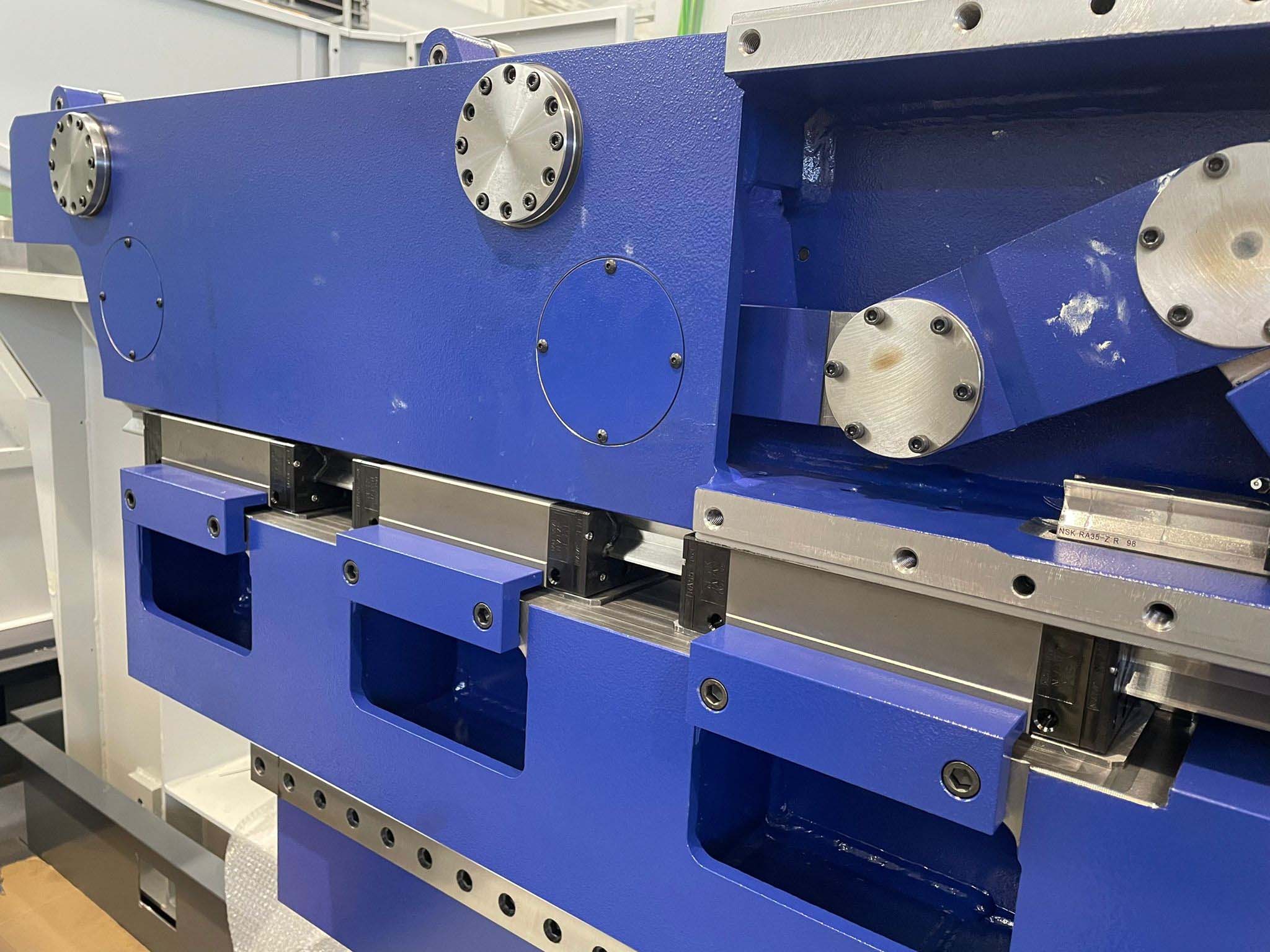

IMSA is therefore using NSK's ground ball screws to achieve the high performance required - even in a relatively small machine. "To transform axial movement into rotary movement, we use two 63mm diameter NSK ZSS series ground ball screws,” says Colombo. “Compared with the ball screws of previous generations, they guarantee greater rigidity and perform better in terms of speed and load capacity. As a result, the machine's working axes can move at feed rates of up to 30m/min.”

Another NSK product family that is extremely important for IMSA designed machines is RA series roller guides, which represent the ultimate in rigidity, load capacity and precision. Their ‘caged roller’ construction technology ensures smooth and silent running and prevents the rollers from crossing to eliminate the risk of damage or premature failure. The roller guides, together with NSK ball screws, are the heart of a solution that guarantees rigid movement in IMSA’s machines.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.