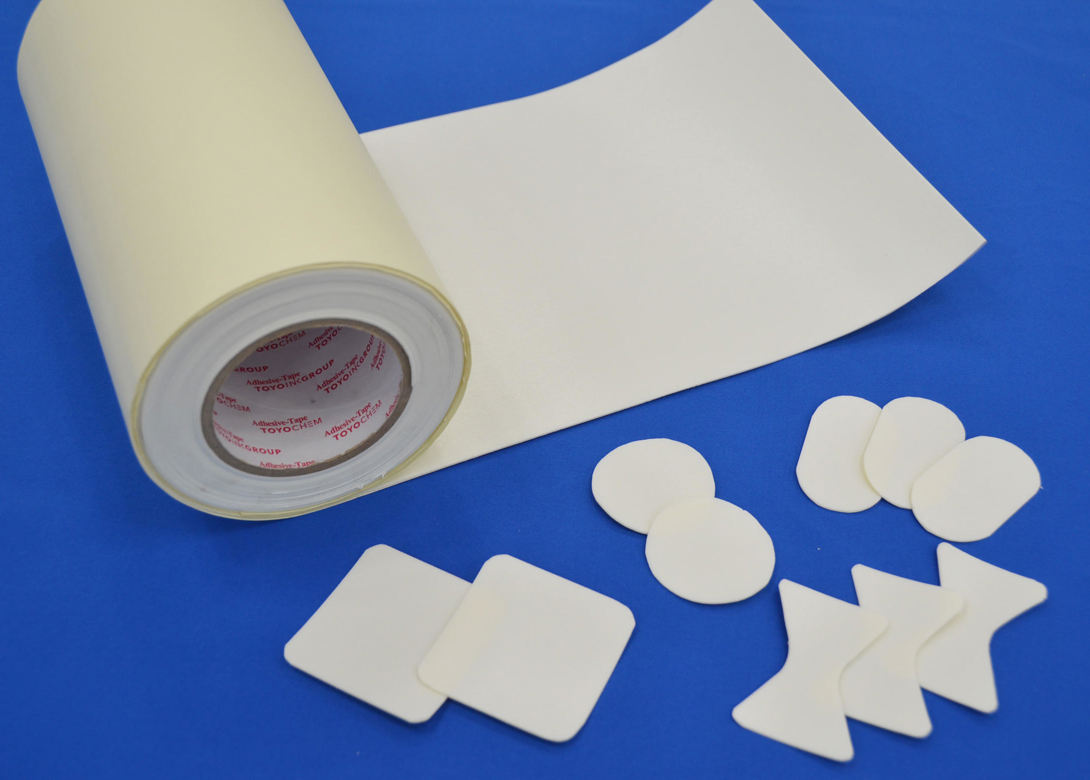

Toyochem Co Ltd, the polymers and coatings arm of Japan’s Toyo Ink Group, has launched a new healthcare use line of pressure sensitive adhesives (PSAs) under its Oribain™ brand of acrylic adhesive solutions.

The new PSA system addresses the demand for medical tapes and surgical dressing materials that offer high moisture absorbency and breathability, thus minimising skin maceration and infection. Moreover, the adhesive compositions are based on acrylics - not silicones - so they do contain any substances that may contaminate coating environments or cause costly bonding issues.

Conventional pressure sensitive acrylic adhesives commonly used in modern medical tapes tend to exhibit low moisture permeability and to easily trap heat and water vapours released from the skin. This often leads to skin irritation, skin maceration, rashes and even bacterial growth. To address this issue, Toyochem researchers applied its advanced resin synthesis technology to form a polymeric composition that substantially raises the moisture permeability rate of the adhesive layer.

"Early evaluation testing by our end customers has produced promising results,” said Nao Nakamura, general manager of Toyochem’s adhesives division. “The new Oribain PSA has consistently reached water vapour transmission rates of 2,000g/m2/24 hours. These values are considerably higher than those of traditional acrylic adhesives, which typically range from 500 to 1,000g/m2/24 hours. We were able to do so, all the while maintaining mechanical performance requirements for adhesion and peel strength.”

Moreover, Oribain PSA systems are acrylic-based and do not contain silicones, which are widely used in today’s medical tape adhesives. Thus, the new PSA compositions do not contain any substances that may contaminate coatings lines or processing environments, for a more user and cost friendly alternative to silicone types.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.