Medical professionals rely heavily on functionality and accuracy of critical medical instruments and devices. Given the highly specialised and costly nature of medical equipment, medical providers deliberately seek medical devices that will withstand the rigors of the healthcare environment. As a specialist in sealing solutions, APM Hexseal offers a full complement of sealing products suitable for use in medical environments.

All medical equipment is subject to frequent sanitisation in accordance with stringent hygienic standards. Original equipment manufacturers (OEMs) serving the medical sector must incorporate reliable sealing hardware into these devices to protect critical electronics from harsh chemicals and other external contaminants, such as transfer debris from an operator’s hands and fingers.

APM Hexseal offers a full complement of sealing products suitable for use in medical environments, including self-sealing boots and hardware, such as nuts, bolts, washers, and screws, that protect delicate electronics from environmental, chemical, and biological hazards.

“Our products are a must have in mission critical applications. When lives depend on a piece of equipment functioning accurately, and down time is not acceptable, APM Hexseal can minimise the risk of failure and help insure the continued and proper function of the instruments and equipment,” comments APM.

How and why is sealing hardware used for medical equipment?

Electronic equipment used in a medical environment needs proper protection from a variety of potential external hazards. Medical equipment failure can lead to devastating and deadly consequences. APM can help prevent that. Sealing boots and fasteners play a crucial role in protecting this equipment from moisture, dust, and contaminants that can damage the sensitive internal electronics.

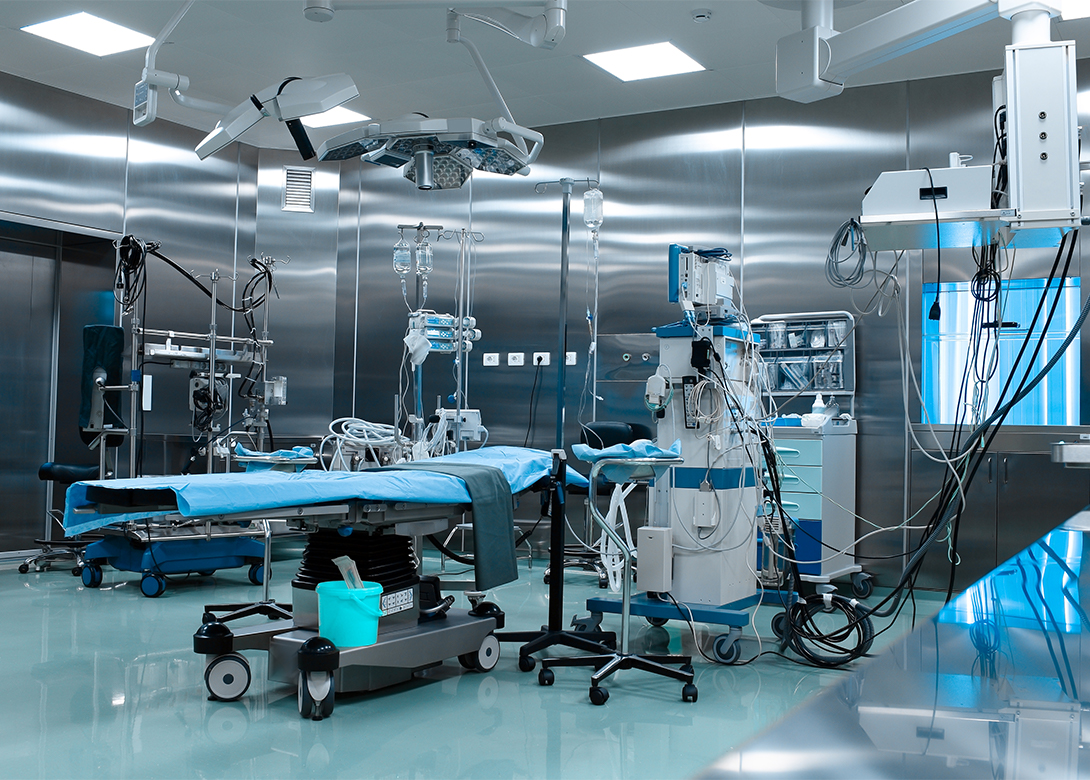

In addition, in order to protect patients and healthcare workers, anything used in a medical setting must withstand rigorous and frequent cleaning and sanitizing to prevent the spread of germs and disease. Instruments such as thermometers, medical imaging equipment, cardiac machines, and ventilators all contain delicate electronics and have the potential to be damaged by environmental hazards or harsh cleaning chemicals. Sealing boots and fasteners safeguard fragile electronics from chemical exposure by properly sealing holes and vulnerable areas where contaminants might otherwise seep into internal components and cause a failure or malfunction.

Sealing hardware is also used to contain essential process fluids used within some medical and mechanical equipment. Leaks in a healthcare setting can compromise equipment function and put patients and healthcare workers at risk, so it’s vital for medical manufacturers to use reliable sealing products.

Sealing hardware has numerous medical applications. Some of the most common include:

- Electronics - the various electronics found in medical offices and hospitals may include computers, monitors, control panels, switches, and more. Medical devices used directly in patient care, such as monitors, respirators, and insulin pumps must be protected from contamination, or potential leaks. Every surface in a medical facility must undergo frequent sanitisation - especially those with human interface. Sealing boots and fasteners allow electronics to withstand continued exposure to harsh cleaning chemicals while keeping moisture from entering the equipment housing. These components also protect against a range of other contaminants, both general and healthcare specific.

- Process fluids - Some types of medical equipment may contain process fluids, lubricants, or coolants. Other devices facilitate the transfer of blood, plasma, or other fluids. Some machinery must reliably contain critical medicines or gases. These devices rely on sealing bolts, screws, and other sealing hardware to reliably contain fluids and gases.

APM Hexseal offers sealing solutions that can be used for a plethora of medical applications. The company manufactures products using durable elastomers that perform well under exposure to caustic chemicals and UV light used to sterilise equipment. The materials used in its sealing hardware function well across temperature fluctuations and do not conduct electricity.

Contaminants in medical devices and hardware

Sealing boots and fasteners protect medical equipment against a diverse set of contaminants, including hazards not commonly found in other industrial settings. Without effective sealing hardware, expensive medical equipment can be damaged by sanitizing chemicals, dirt and dust, food/beverage spills, blood and other bodily fluids, grease, as well as lubricant/coolant leaks.

Types of sealing components commonly used

Medical sealing boots and fasteners from APM Hexseal are specially designed to withstand hazardous environments. Its portfolio of sealing products includes sealing boots for switches and circuit breakers; self-sealing screws, nuts, bolts, and washers; as well as fully customised sealing solutions.

APM manufactures sealing products using a range of elastomers, allowing design engineers to target specific resistances and physical properties. All its elastomers feature high resistances to chemicals and abrasion, and each have individual properties that make them unique. Common elastomer options include silicone, fluorosilicate, Viton® A, Buna N (Nitrile), neoprene and EPDM (Ethylene propylene).

Materials and applications

When selecting sealing hardware materials for medical equipment design, variables such as equipment location, level of human interface with equipment, surrounding environment, potential contaminants, as well as motion and potential for friction or pressure against the instrument, which must be considered. Also, identifying whether the system is static, reciprocating, or rotary.

Different materials are better suited for some systems than others. Static seals provide a tight seal between two stationary surfaces, reciprocating seals are best when the only potential motion is linear and rotary seals are used between oscillating or fully rotating components, such as those found in many medical pumps. Rotary seals must be highly flexible without sacrificing durability, while static seals can be relatively stiff. The experts at APM Hexseal can help identify the most appropriate elastomer to match a particular application.

Differences between medical use cases

Displays and keyboards are used in virtually every medical setting to display vitals or to guide scopes. This equipment must be completely sterilised in between surgeries in an operating room, whereas sterilisation procedures in a pediatric office or medical clinic may be less stringent or use a different cleaning process. While both are susceptible to contaminants and must undergo vigorous cleaning procedures, the operating room equipment is subjected to harsher demands, including more rigorous cleaning protocols, wash downs, as well as higher risk of biological contamination.

Now, consider instruments used in an ambulance or as part of a mobile medical set up. For mobile medical equipment, movement becomes a serious consideration. Sealing hardware in these applications must withstand constant jostling and vibration without loosening or degrading. In addition, these instruments are often sanitised on the go, using sprays or chemical wipes. Mobile medical instruments are perhaps the products that most need to be sealed and protected. These devices are used in the community where there is more exposure to potential hazards such as dust, dirt, and transfer debris from tactile interface and are likely to be utilised at the scene of a life threatening emergency, where failure is not an option.

These examples illustrate the diversity of environments that subdivide the medical industry, along with the myriad factors that can influence the selection of a robust sealing solution.

APM Hexseal offers premium self-sealing fasteners that meet the requirements of the healthcare sector. The company works with a broad range of elastomers, providing sealing performance that is second to none. It has the experience and expertise to provide reliable sealing solutions that will protect medical equipment and keep it functioning, under the most demanding conditions.

Since 1947, APM has developed and manufactured sealing solutions that prolong the life of sensitive electronic and mechanical components and systems in hostile environments. It offers a wide variety of elastomeric covers and sealing hardware, including a complete line of reusable, self-sealing fasteners and sealing washers.

“From self-sealing boots and fasteners in a wide array of elastomer options, to a full design and manufacturing team ready for custom engineered sealing solutions, we have what you need to maximise performance from every component. To learn more about our offerings and capabilities, contact us today and let us help find the perfect sealing solution. When failure is not an option, Cover it. Seal it. Protect.”

www.apmhexseal.com

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.