By Guido Wolf and Szmond Stachlewski of Expanite AS

Corrosion resistant stainless steel is widely used in industry and trade due to its outstanding properties. Despite its numerous advantages, particularly its resistance to corrosion in numerous media, stainless steel also has considerable weaknesses that sometimes severely limit its application.

One of these weaknesses is its susceptibility to cold welding or galling, which can occur particularly with screw connections. Surface hardening offers a solution to this problem.

Galling on stainless steel

Galling can be favoured by various aspects, such as insufficient surface hardness, excessive roughness or lack of lubricants. Nevertheless, fasteners are essential in many applications to allow for particularly frequent assembly and disassembly, or high tightening torques. It is therefore important to carefully tailor the properties of such elements.

When fasteners are jammed due to galling, their removal can turn out to be an enormous challenge, especially if it needs to be done without damaging the affected bolt or destroying the associated nut.

Surface hardening, a process in which only the surface layer (few to tens of microns) of a workpiece is hardened, has been proven to significantly improve the seizure behaviour of stainless steel screws. The diffusion-based process increases the hardness of the surface through solid solution hardening and subsequently reduces its susceptibility to plastic deformation. Depending on the material, the corrosion resistance is maintained or even improved, and the stiffness of the base material is not impaired.

The process

Surface hardening is not an applied coating, but a diffusion-based thermo-chemical surface hardening process. Although classic processes for the surface hardening of corrosion resistant stainless steels have been available to the industry for some time, their application has two main disadvantages. Firstly, all classic processes such as salt bath processes are known to reduce corrosion resistance. On the other hand, the hardness values of stainless steels usually hardened with nitrogen or carbon drop very quickly, i.e the hardening depth is only a few micrometers and the underlying base material is very soft, which can potentially lead to the ‘eggshell’ effect.

In contrast, Expanite has developed its proprietary technology SuperExpanite®, having solved those shortcomings as a priority. With this technological process not only the outermost layer but also the underlying material is hardened to a greater depth, which also contributes to an improvement in corrosion resistance in many cases.

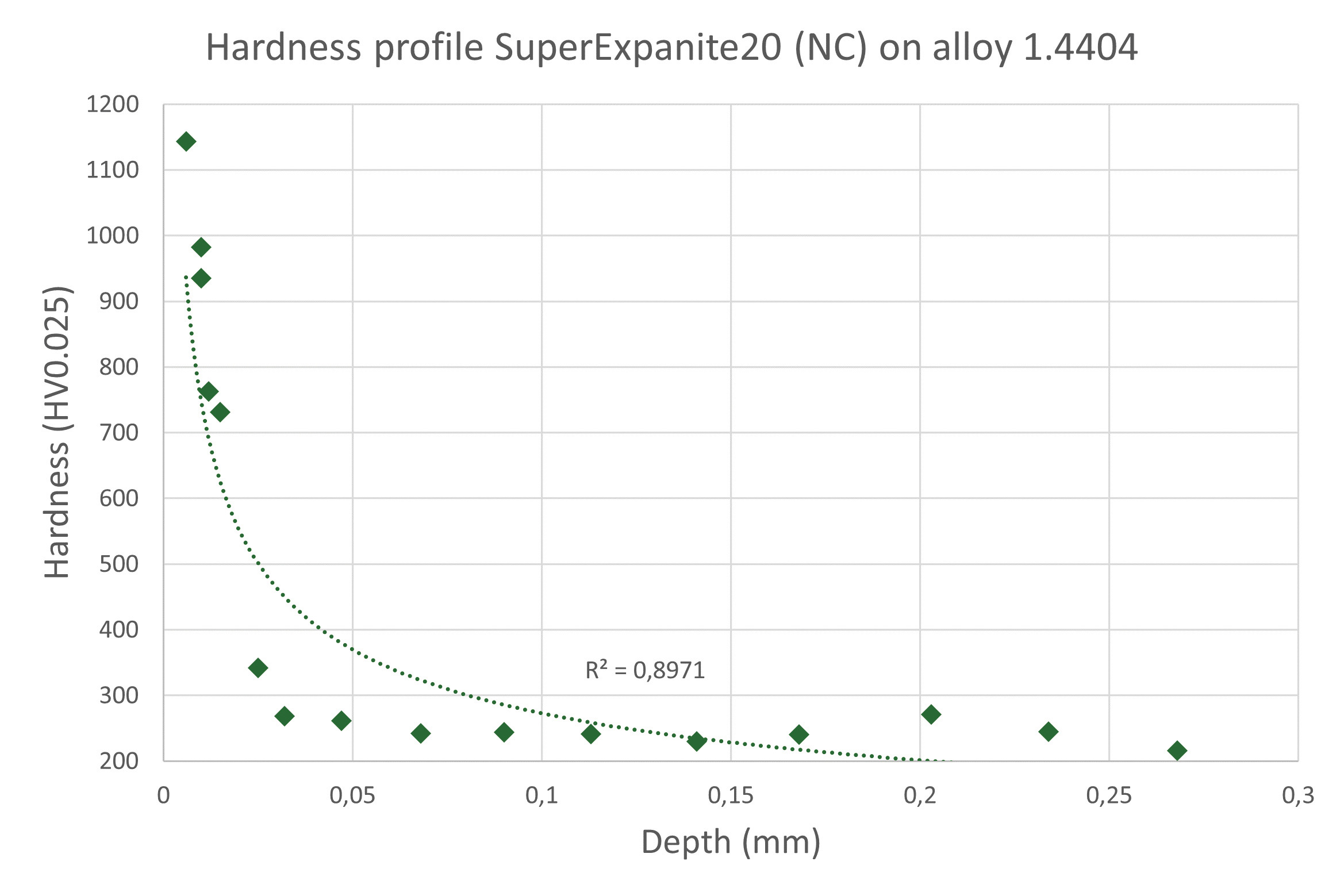

A two stage process is used in Expanite’s treatment for stainless steels, in which nitrogen is introduced deep into the surface area in the first step called ExpaniteHigh-T (high temperature process), whereby the material is hardened to approximately 300HV for austenitic materials and 850HV for alloys with martensitic structure to a depth of up to 1mm. In the second process step, ExpaniteLow-T, the workpiece is heated to temperatures below 500°C and the surface layer is hardened to 1,100HV –  1,300HV at a hardening depth of 5µm - 30µm (depending on the solution). The hardening is achieved by incorporating large amounts of interstitial carbon and nitrogen.

1,300HV at a hardening depth of 5µm - 30µm (depending on the solution). The hardening is achieved by incorporating large amounts of interstitial carbon and nitrogen.

By combining the two process steps, the so-called ‘eggshell’ effect, which occurs in most surface hardening processes, is avoided. This offers a decisive advantage for numerous applications that require improved load-bearing capacity. The hardness profile can be seen in Figure One:

Wear resistance

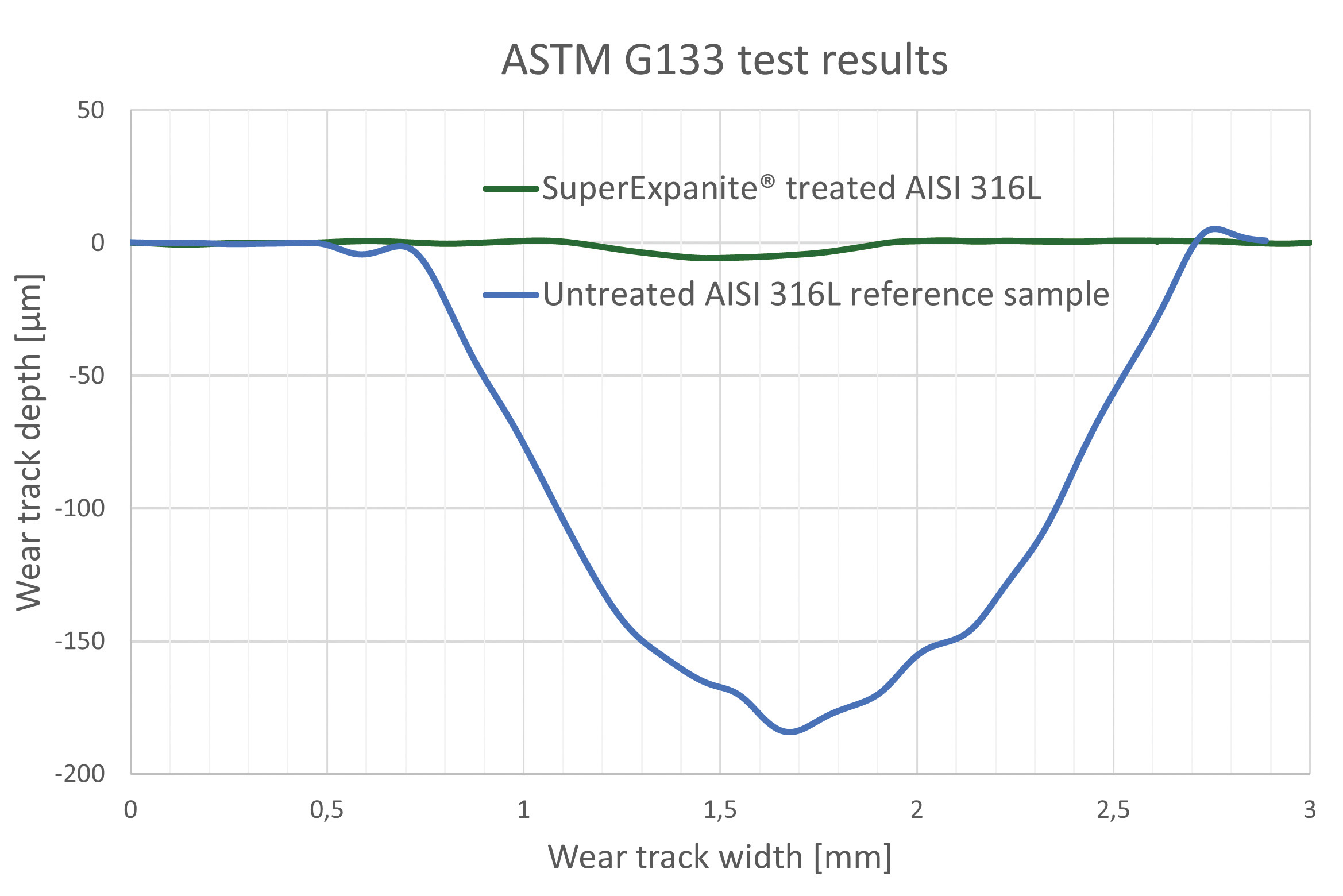

To test wear resistance, Expanite tested some 316L samples hardened using its SuperExpanite® process to ASTM standard G133. In this procedure (Figure Two) the SuperExpanite® treated test specimen is subjected to the reciprocating motion of 100Cr6 counterpart, under a contact pressure of 25N. The wear volume is determined after a sliding distance of 100 metres. The 316L sample with SuperExpanite® is 125 times more abrasion resistant than the untreated sample.

To test wear resistance, Expanite tested some 316L samples hardened using its SuperExpanite® process to ASTM standard G133. In this procedure (Figure Two) the SuperExpanite® treated test specimen is subjected to the reciprocating motion of 100Cr6 counterpart, under a contact pressure of 25N. The wear volume is determined after a sliding distance of 100 metres. The 316L sample with SuperExpanite® is 125 times more abrasion resistant than the untreated sample.

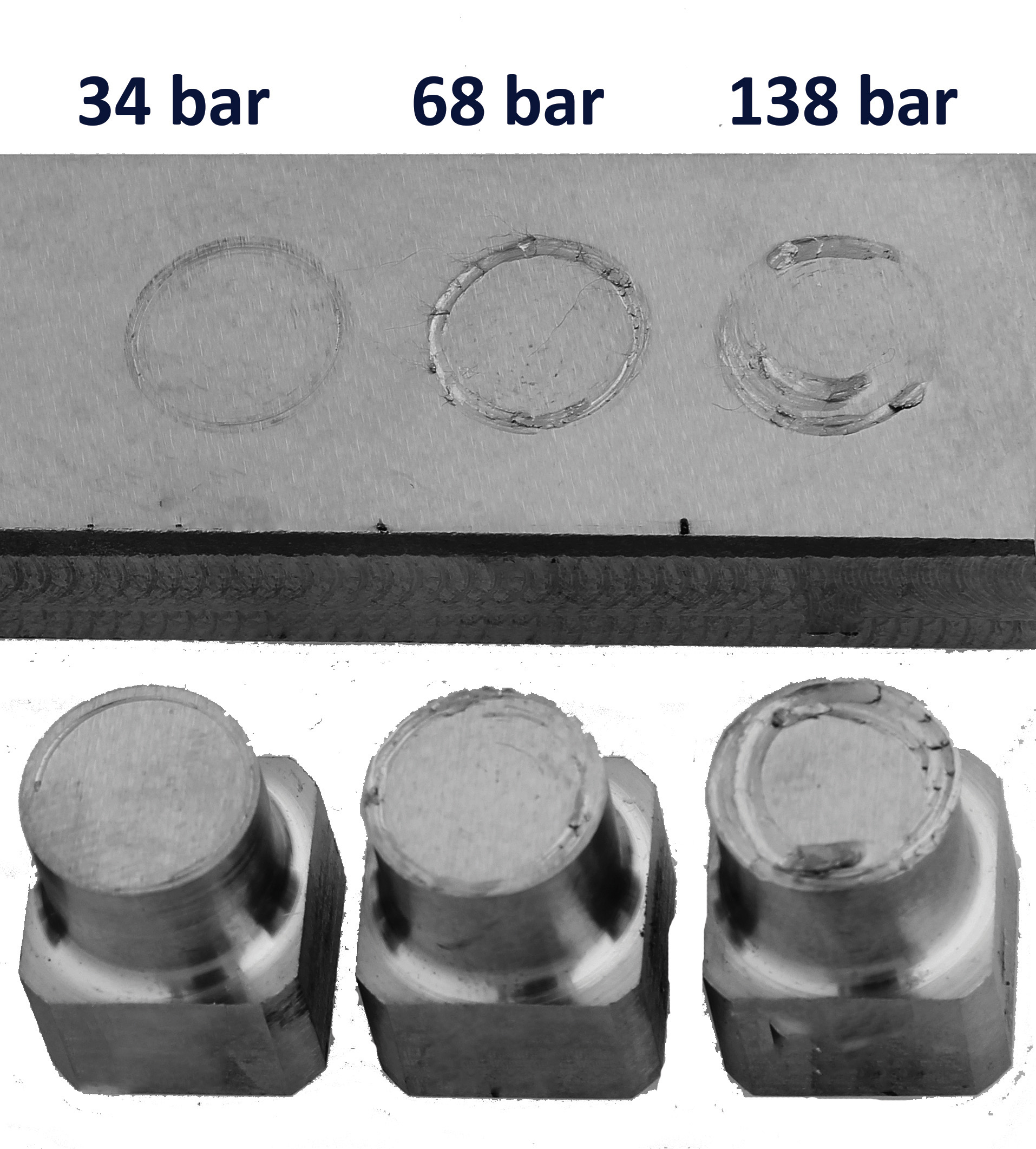

Following the ASTM G133, an ASTM G98 galling test (cold wear) was carried out with test specimens made of AISI 316L, the results of which are shown in Figure Three and Figure Four. In comparison to the unhardened test specimens, which already exhibit galling at a contact pressure of 35 bar, the test specimens hardened with SuperExpanite® do not show any galling even at a contact pressure of 2,758 bar. Even though the first plastic deformations occur at this pressure due to the yield strength being exceeded. The risk of galling is therefore eliminated in the case of both friction partners being hardened.

Corrosion resistance

Although the basic intention of conventional surface hardening processes is to produce harder surfaces, this is usually at the expense of corrosion resistance. This is where the Expanite process comes in. Tests have shown that 316L samples hardened with SuperExpanite® can spend up to 1,000 hours in a salt spray chamber without showing signs of corrosion (Figure Five).

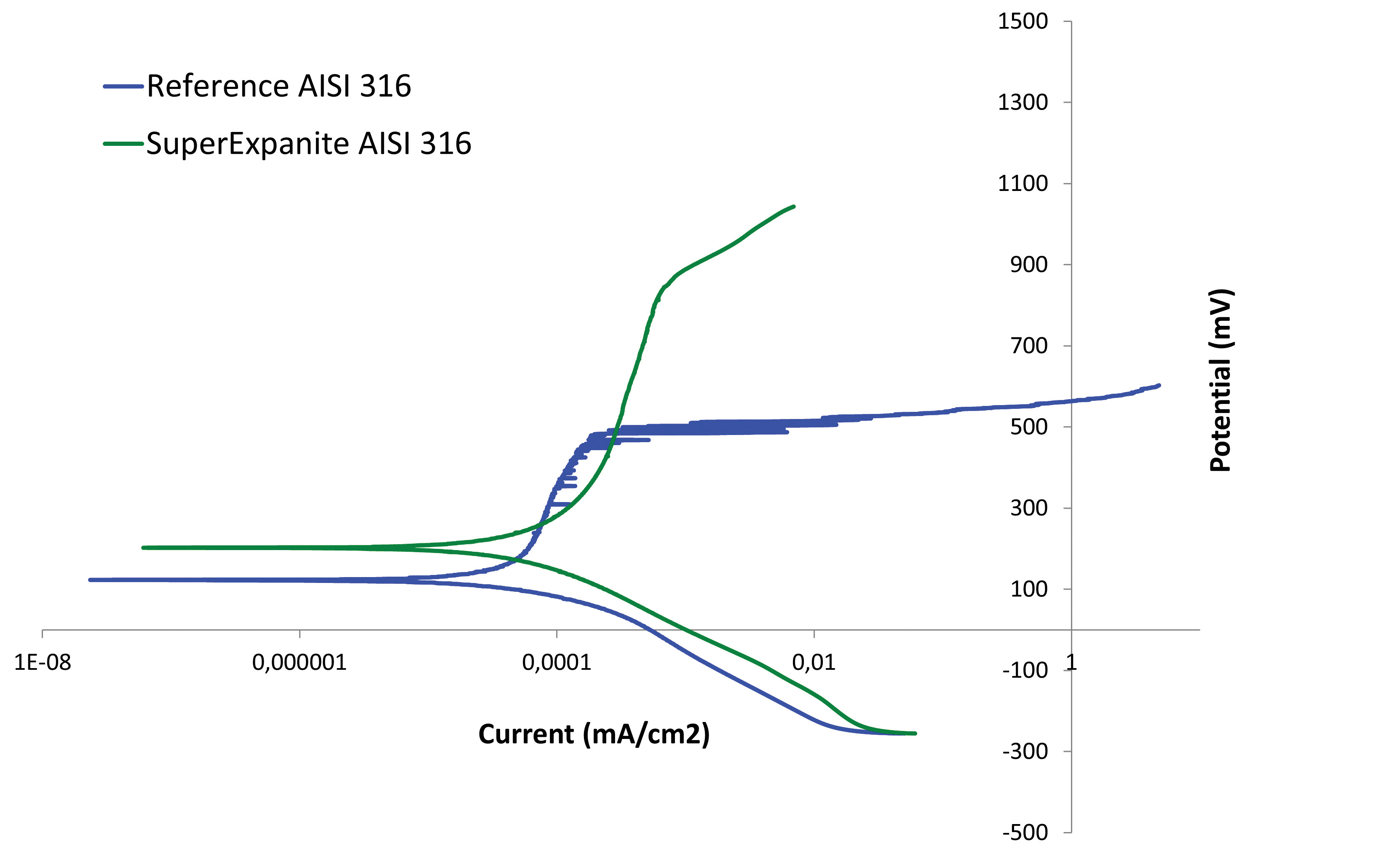

In some cases, the pitting corrosion resistance can even be significantly increased by the Expanite surface hardening process, even beyond the level of the unhardened base material. (Figure Six). This effect is caused mainly by the large amount of nitrogen dissolved in the surface layer. A common formula for calculating the pitting resistance equivalent number (PREN) for alloys not containing tungsten, is:

PREN = %Cr + (3.3 x %Mo) + (16 x %N)

It is easy to notice a relatively large 16x modifier in front of the nitrogen content expressed in weight percent (wt %). This means that even small amounts of nitrogen have a significant positive influence on pitting resistance.

With the assumption of applicability of this equation for large amounts of dissolved nitrogen[1], usually between 5wt% and 13wt%[2], the PREN number can be calculated. For the AISI 316L alloy the calculated PREN numbers then range from around 100 even up to 230. A minimum of four-fold increase over untreated material, which has a PREN number of around 24. The underlying ExpaniteHigh-T zone can be characterised with a PREN number of around 30, providing additional improvement even if the case hardening have been damaged or worn down.

A potentiodynamic polarisation curve for SuperExpanite® treated and reference AISI 316 material is shown in Figure Six. This test is a common tool used to evaluate the pitting corrosion potential and characteristics of a metal. There are several highlights that can be derived from the graph, showing the undeniable positive influence of SuperExpanite® treatment on the pitting corrosion resistance of austenitic alloys. Firstly, the open circuit potential of SuperExpanite® treated sample is around 100mV higher than for the reference, suggesting better corrosion resistance in the absence of galvanic coupling. The polarisation curve of the reference material also shows a much narrower passive region, which is characterised with many intermittent peaks (rugged line). Those lines indicate a sudden increase in current density (increased corrosion rate) and subsequent repassivation – initial pit formation. The plot obtained for SuperExpanite® sample is free of those irregularities, and the material stays in the passive zone for potentials almost twice as large, with much more gradual decline towards the breakdown potential.

Environmentally friendly

Despite their widespread use, conventional surface layer hardening processes have various disadvantages. Harmful chemicals such as fluorides, chlorides, molten salts, etc, are used. SuperExpanite®, on the other hand, which is produced using the two stage process described above, is characterised by an environmentally conscious approach. Without the use of harmful chemicals, and no polluted wastewater, Expanite represents an environmentally friendly and sustainable alternative.

To summarise, the nitrocarburising process specially developed by Expanite delivers excellent results in terms of both hardness and corrosion resistance for all stainless steel materials, not just limited to individual alloys. The process is therefore recommended for all types of stainless steel screws and fittings to extend the service life of the corresponding components and thus ensure increased product safety and interchangeability.

References

[1] Bottoli, Federico, Morten S. Jellesen, Thomas L. Christiansen, Grethe Winther, and Marcel AJ Somers. ‘High temperature solution-nitriding and low-temperature nitriding of AISI 316: Effect on pitting potential and crevice corrosion performance.’ Applied Surface Science 431 (2018): 24-31.

[2] Christiansen, Thomas, and Marcel AJ Somers. ‘Controlled dissolution of colossal quantities of nitrogen in stainless steel.’ Metallurgical and Materials Transactions A 37 (2006): 675-682.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.