A team of 40 Hydratight engineers from Germany, Holland, France, and the UK, operating under Covid-19 restrictions, was tasked with lifting vessel covers, performing on-site machining and controlled bolting on a number of vessels and heat exchanger joints at an industrial complex in Germany.

During the plant’s annual shutdown, Hydratight engineers reviewed and replaced bolts on vessel covers and heat exchangers. Hydratight has on-demand access to Enerpac bolting and machining tools as part of the Enerpac Tool Group. Where necessary the team cleaned and removed welding rings on lids, shells and vessel chambers using a variety of industry leading tools and on-site machining techniques, including a specialised Mirage MM2000E milling machine.

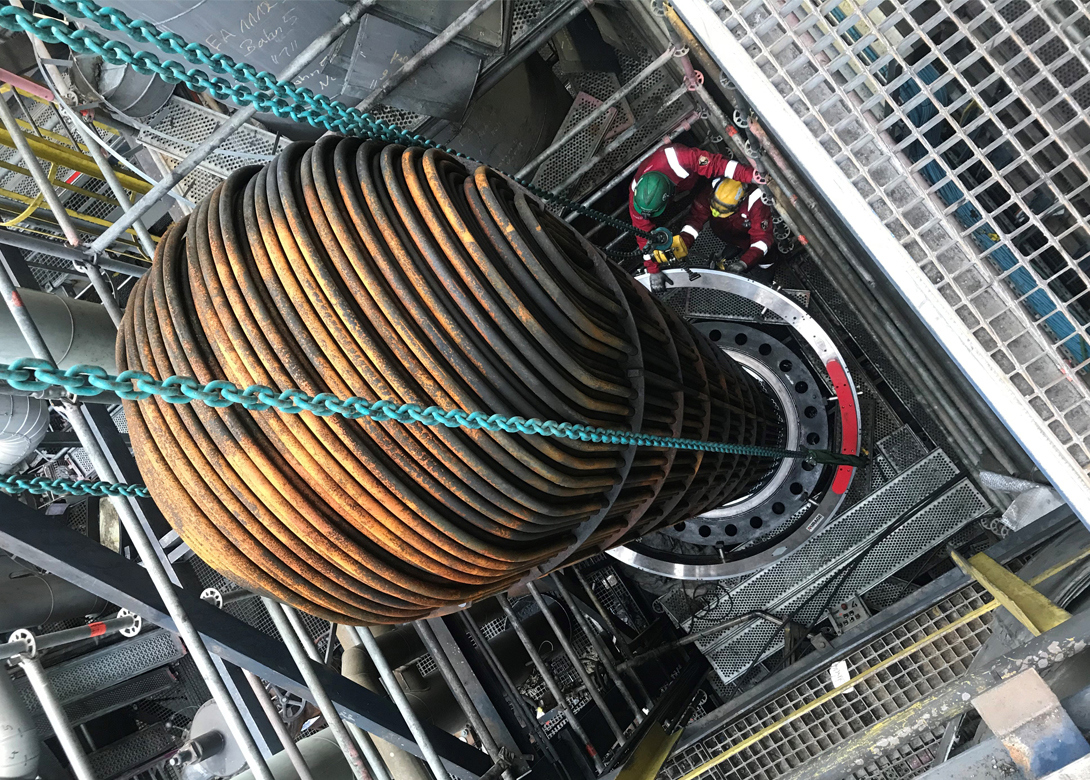

For the largest vessel, the vessel cover weighing 5 tonnes was removed and refitted using Enerpac low-height skidding and compact cube jack systems, and a turntable. Before refitting, the cover was machined using the Mirage MM2000E milling machine, also part of the Enerpac tool portfolio, to ensure an accurate metal-to-metal seal.

“We are delighted to have assisted our customer during their maintenance shutdown. Our ability to bring together a team of experts to deliver these services even in times of Covid-19 is testament to our resilience and commitment to customer service,” said Chris Huiskens, commercial manager service and rental, Hydratight.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.