The new Huck® Magna-Lok MX® - available from Star Fasteners - has been specially designed to replace M10 bolting, enabling reduced assembly times and production costs.

Many hours are spent engineering, designing and finally turning raw materials into finished parts, but the next manufacturing step is often assembling and fastening these parts together. While welding, bolting and solid rivets have long been utilised in demanding, load-bearing or high vibration applications, today's manufacturers have several strong reasons to consider a proven alternative to these traditional methods.

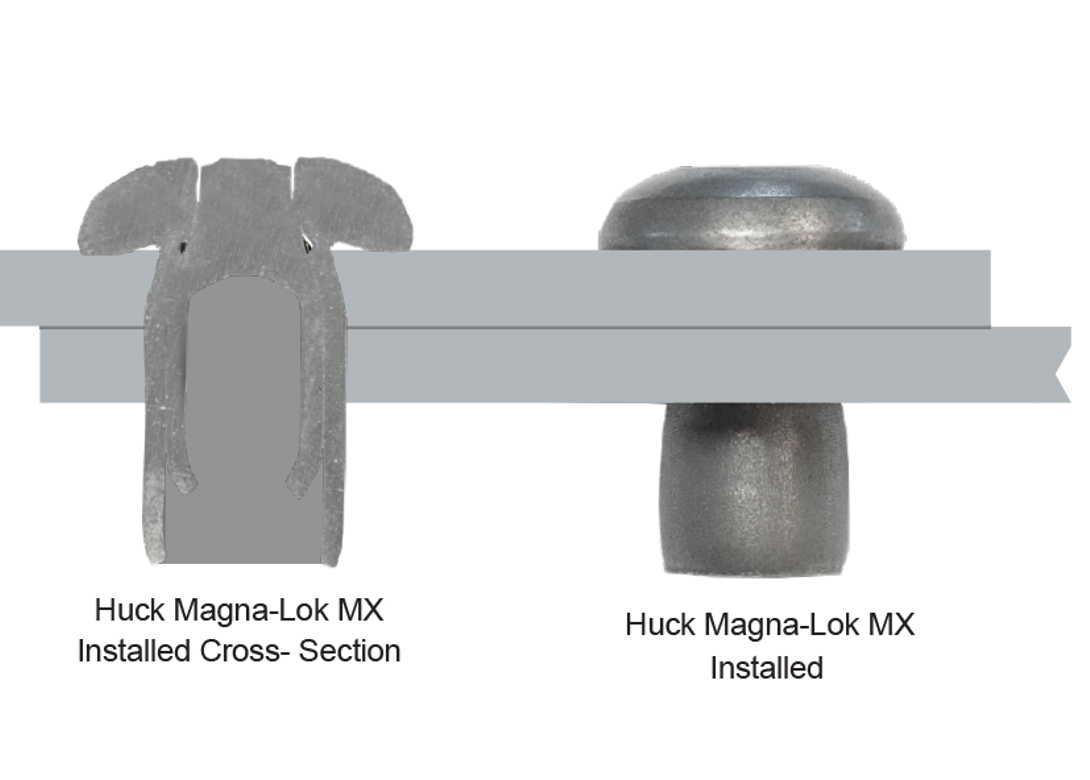

Huck structural fasteners are proven to hold up over years of service in demanding high stress, high vibration environments. Whilst ensuring a secure joint, they can be effectively used with virtually any metal, and dissimilar metals with dissimilar coefficients of thermal expansion present no problems. Varying material thicknesses in a joint are readily accommodated, and surface finishes are not damaged. The Magna-Lok MX has been designed to accommodate standard produced holes traditionally suitable for M10 bolts (the recommended holes size for this is 10.8mm/11.2mm). For applications where only one side of the joint material is accessible, performance-engineered Huck structural blind fasteners can often meet design requirements.

The Huck Magna-Lok MX delivers repeatable and consistent joint performance, with washer-free water resistance, fastener should be application tested to ensure suitability, as well as excellent shear, tensile and fatigue performance. Once installed Magna-Lok MX will consistently perform over time, even when exposed to changing loads - vibration / expanding or contracting - eliminating the need for regular maintenance.

Magna-Lok MX is installed quickly and easily in a matter of seconds, the installation only requires access to one side of the assembly, meaning only a single labourer is needed. This ensures the assembly is completed both quickly and cost-effectively. With excellent shear, tensile and fatigue performance, the permanent nature of the joint ensures reduced maintenance costs; the joint does not need to be regularly checked or re-torqued, eliminating ongoing costs over the product lifetime.

The Huck Magna-Lok is a versatile, hole filling fastener that can be installed with conventional and battery-operated installation tools. It has a unique circle-lock design creates an internal lock during installation that virtually eliminates pin pushout by mechanically locking the pin to the sleeve.

Fastening with Huck structural fasteners delivers five key benefits

Safety – the heat generated by welding can often reduce the strength of the metals being joined, and damage critical surface coatings. In addition, welding dissimilar metals or pieces of varying sizes can be a challenge. Welding also often requires an ongoing process of inspection, with many of these procedures being both costly and time-consuming.

Simplicity – Huck fasteners are easy to install and require a minimal amount of training. The Huck system only requires a single trigger press to deliver high, consistent preload. No operator discretion or adjustment required.

Speed – as the MX is a blind fastener it just takes one operative to install it. Just the time needed to put the fastener into the pre-prepared hole, to apply the tool to the pin and initiate the installation cycle (approximately 3 - 4 seconds).

Cost saving – a quick visual inspection is all it takes to ensure a solid joint. Once installed, there are no ongoing maintenance costs.

Structural integrity – creating semi-permanent joints that will perform in extreme conditions for years to come without the issues of weld fatigue.

Huck structural blind fasteners are not designed to replace all welds. These fasteners can leave a protrusion, which may not be acceptable for some applications. However, there are many applications, where M10 bolts have been traditionally employed, in which these fasteners are a viable alternative.

As a well established leader in the global Huck fastener distribution network Star Fasteners is committed to supplying customers with the most innovative fastening solutions on the market. Working with a diverse range of end users and distributors from across a number of industries including general engineering, rail, solar, wind power automotive, marine and construction markets. In fact, they are widely used in any industry where a quality, strong and dependable fastener is a required making application possibilities endless.

www.starfasteners.co.uk

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.