Howmet’s HuckBolt fasteners have been specifically designed for industrial applications, engineered for a higher level of resistance against vibration.

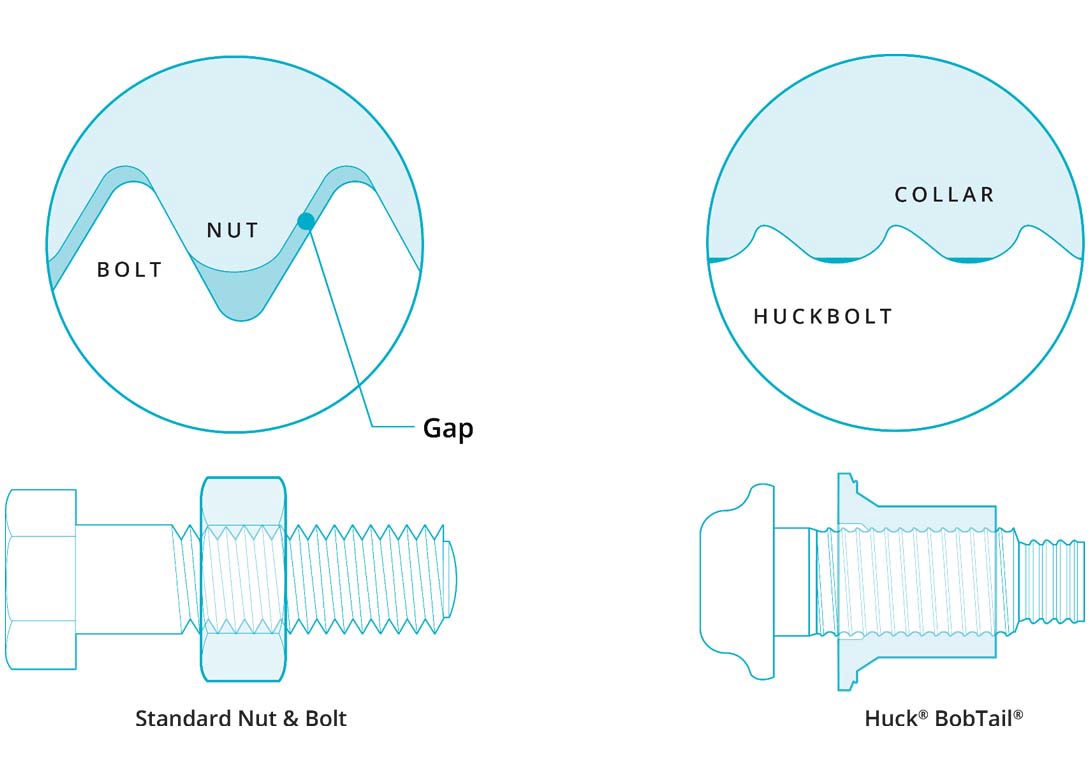

HuckBolts are installed using direct tension and swaging, so there are no gaps between collar and bolt threads – a common source of loosening in conventional nuts and bolts. Full metal to metal contact between the swaged on collar and the pin maintains consistent clamp force, even in the harshest, vibration filled applications.

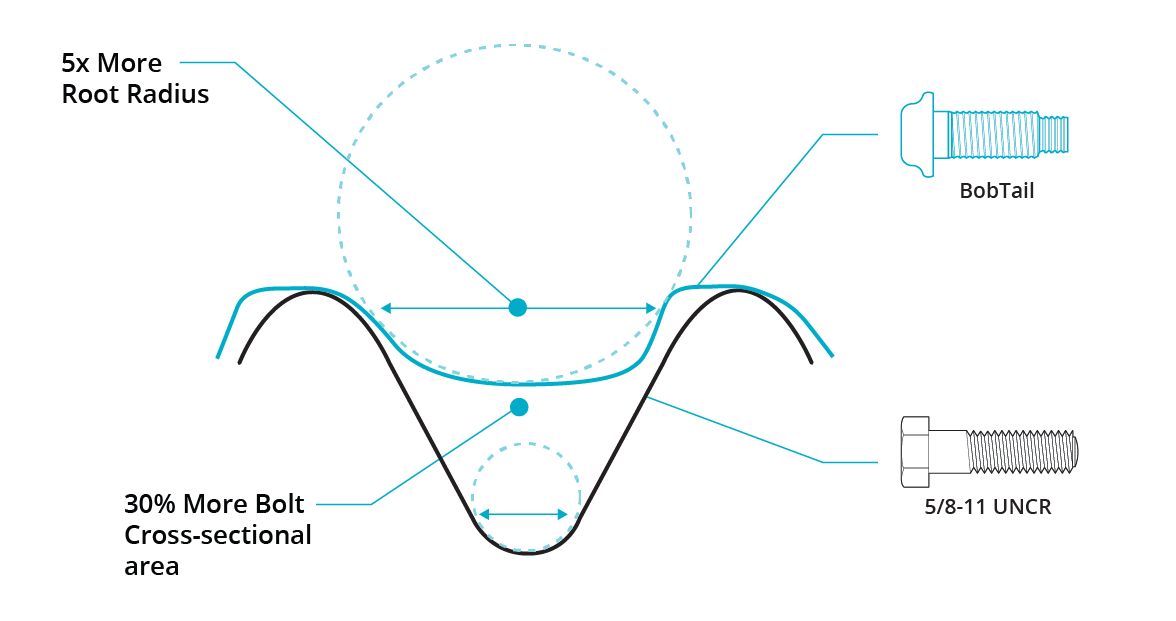

Compared to conventional bolts, HuckBolts have 30% more cross sectional area and a larger root radius, resulting in a much stronger and more secure joint. This delivers five times the fatigue strength, and up to five times larger root radius than regular bolts.

HuckBolts are not subjected to the twisting force of torsion that a torque wrench applies to a conventional bolt. So, they can safely be taken to higher preload values, resulting in higher clamp, higher strength, and the highest level of vibration resistance of any fastener. Even in the most vibration intensive environments, Howmet ensures its Huck fasteners maintain their structural integrity for the life of the joint.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.