During periods of no use is the perfect time to check seals for any signs of damage and wear that may need addressing. It’s important to do this as seal failures can lead to equipment problems which may be detrimental to equipment and business. Here, FPE Seals Ltd looks at best practice when it comes to seals maintenance during periods of no use.

Whether dealing with hydraulic or pneumatic seals such as wiper seals, they must be able to withstand a range of environments and practises such as extreme temperatures, high pressures, chemicals and contamination.

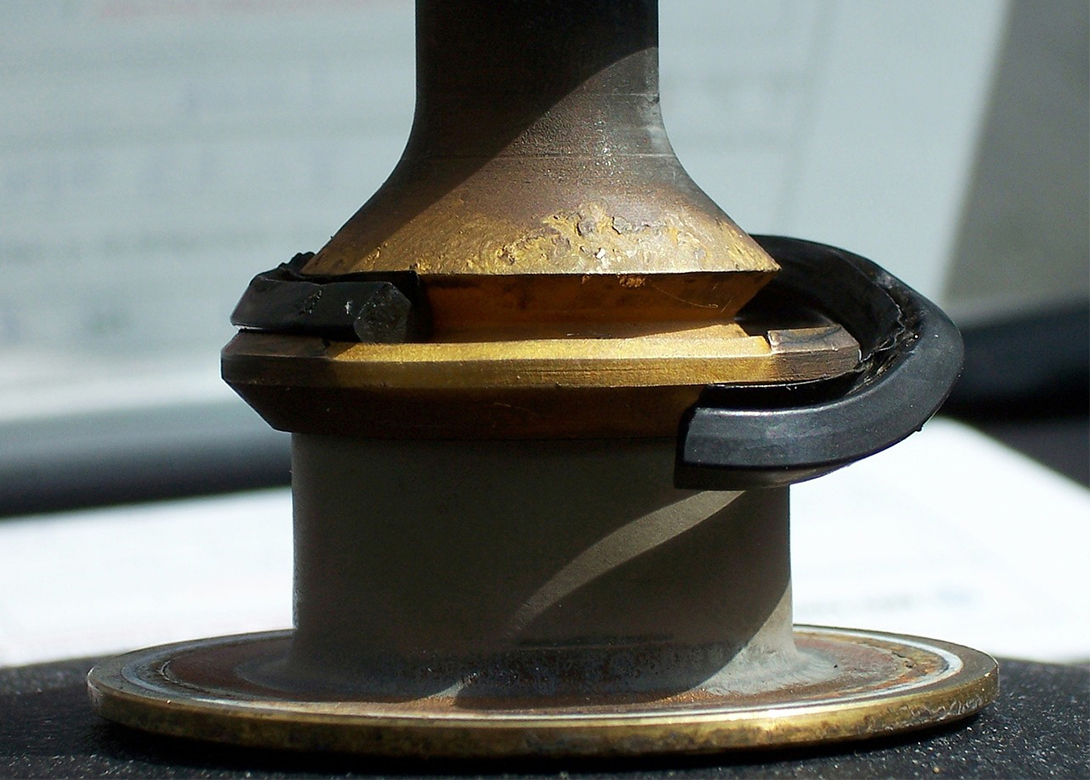

If a seal is in a period of no use, storing them properly can prevent future failure. Properly storing seals includes putting the seals and their hardware in a cool environment. You must also disassemble the seals and sort each part individually, making sure not to store seal faces together as they could end up losing their flatness.

Lubrication is a must in seals and most machinery as it can prolong the life of seals due to the motion they are usually under. When looking at the seals, check that lube is present. If there is none present or only a small amount, place some grease around the seal. Checking for grease is important to prolong the life of a seal.

Just because the machinery is not being used does not mean that contamination is not still present in the seal. If the seal has not been checked after its last use, then contamination may still be present. Contamination may come from metallic shavings, powder, dirt, mud, grit, and other solid particles. These may be picked up during operation and can damage the seal when passing through.

If the seal has been stored somewhere that has a high temperature, the heat can cause damage to the seal. The heat can cause the seal to harden and degrade quickly. The material of the seal can break off when hardened, and this can then cause more contamination along the whole machinery or pipe network.

The pressure that a seal has been under could cause it to fail. This might have been because it is over pressurised. Check for pressure strikes in seals. If there is any, a seal must need to be replaced with one that is made to be under higher pressure.

If there has been a corrosive fluid used, then this may cause a breakdown in the seals’ material. You need to have made sure that the material the seal is made out of is right for the fluid passing through it. Especially when connecting a seal to a hydraulic system using chemical fluid, this may create fractures in a material. The chemical deterioration can cause swelling or shrinking of the seal.

Whether your seals or being used or are in storage, maintenance is important to keep them in good condition for present and future use to make sure they don’t fail.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.