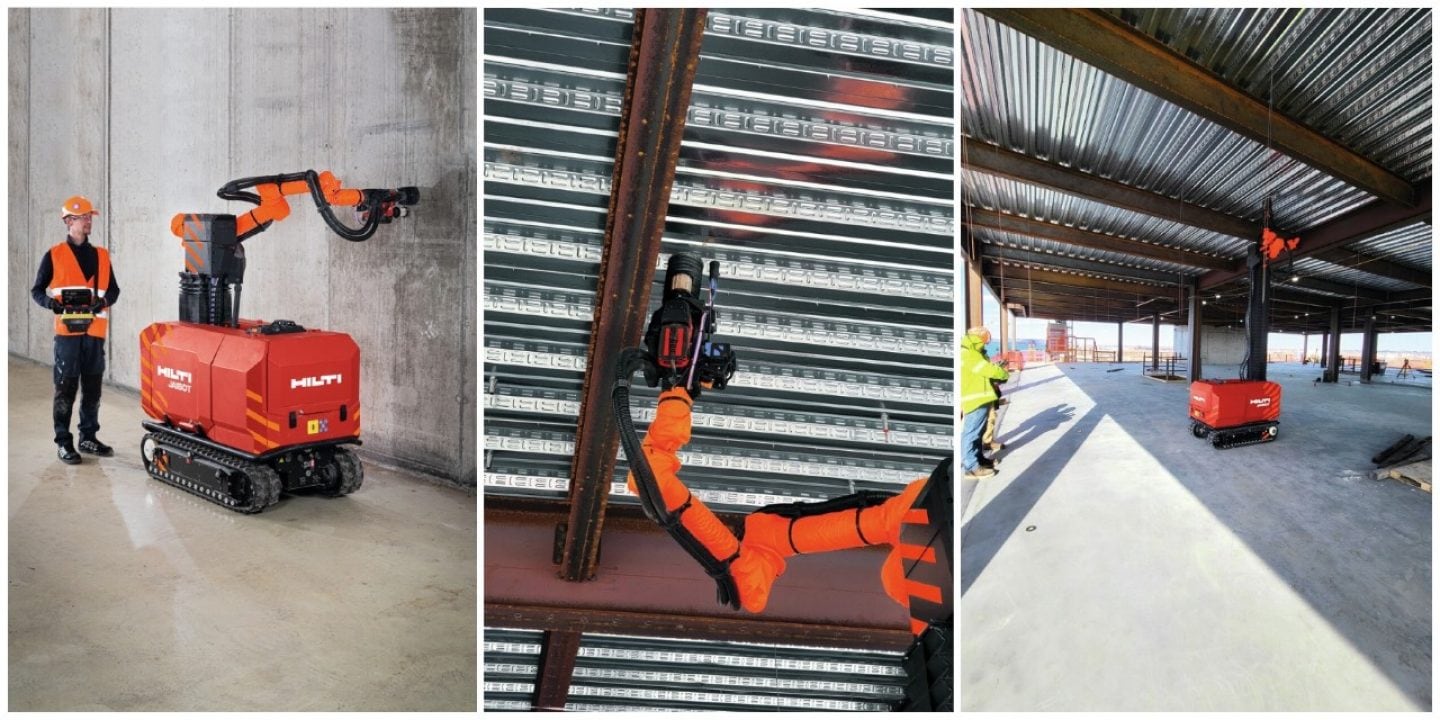

Hilti has updated its mobile drilling robot Jaibot with the release of several new features including autonomous drilling on corrugated metal deck ceilings and concrete walls, as well as improved safety, simplifying use and improved accuracy.

The Jaibot is a semi-autonomous, mobile drilling robot for anchor holes that executes tasks based on digitally planned data. Since its introduction in late 2020, the Jaibot has been deployed in many construction projects globally, helping MEP, ceiling installation and general contractors to improve productivity, ensure safety and deliver constant, predictable performance. Hilti is now announcing the release of a series of new features that will further boost productivity and support adoption in the industry.

In support of complex ceiling types, the Jaibot can now identify and map installed profiles of corrugated sheet metal deck structures, align with the digital plans and automatically adapt planned drill holes to pre-defined installation zones. To avoid obstacles, such as existing installations or structural elements, the Jaibot can detect these objects and adjust its working area and arm movements accordingly. In addition, the Jaibot can now also drill and mark holes in vertical concrete walls at heights between 0.9m - 4.8m.

As in the past, the Jaibot executes drilling tasks automatically while the user interface enables the operator to ensure optimal placement and control.

Hilti is also releasing a range of features to improve safety, simplify use and improve accuracy. To provide workers with greater protection against dust, the Jaibot’s vacuum system can be upgraded to deliver 30% higher dust removal performance. The integration of a new sensor system improves hole drilling depth accuracy and distance measuring.

On the Hilti cloud application, customers benefit from new 2D structural floor or installation plan upload options which allow for increased background information, improved user management and filtering by diameter to establish a drilling path and plan execution, as well as enhanced reporting with features like Field to BIM data and drilling progress. An option to export data and print a 2D plan for potential field rework is also available.

“When we first announced the Jaibot, we promised customers that we would listen and learn as to what it needs to successfully automate tasks on the jobsite,” says Julia Zanona, product manager for the Jaibot. “We are confident that the new features address the needs of our Jaibot customers and are a clear sign that we are committed to continuously enhance worker productivity through automation.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.