Master Bond UV15X-6Med-2LV is a UV curable, non cytotoxic adhesive that features optical clarity and abrasion resistance. Not only can it be utilised for bonding, but it can also be employed for sealing, coating, and encapsulating purposes.

It has a high degree of flexibility with an elongation that exceeds 100% and a low tensile modulus of 20,000 psi - 50,000 psi at room temperature. This flexibility allows it to withstand extreme thermal cycling and mechanical shock without inducing stress on components/parts. It bonds well to similar and dissimilar substrates including glass, metals and plastics.

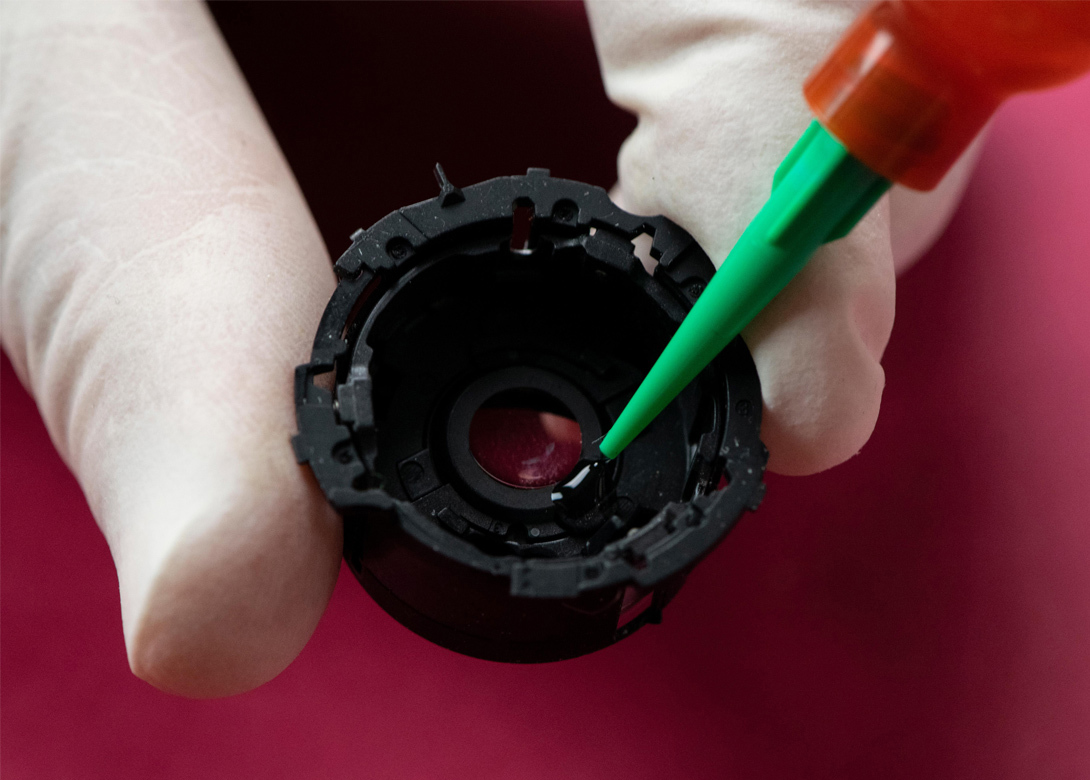

UV15X-6Med-2LV is a one part system that cures upon exposure to a UV light source emitting at a wavelength of 320Nm to 365Nm with an energy output as low as 20 - 40 milliwatts/cm2. It can cure in as little as 10 to 30 seconds, and in sections up to ¼ inch. A successful curing process entails complete exposure to the UV light source, for this reason there should be no shadows or UV blocking agents in the substrates used. As a one part system, it requires no mixing prior to use.

This compound has a medium viscosity of 20,000cps - 40,000cps and is not oxygen inhibited. It is electrically insulative with a volume resistivity of more than 1012 ohm-cm at room temperature. UV15X-6Med-2LV has a refractive index of 1.50. It is serviceable over the temperature range of -80°F to +250°F.

Since UV15X-6Med-2LV meets the ISO 10993-5 certification it can be used in medical device manufacturing applications where this requirement is vital. It has good resistance to water, cleaning agents, e-beam, ethylene oxide and gamma radiation. Packaging is available in syringes, ½ pint, pint, quart and gallon sizes.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.