Growermetal’s range of fasteners has seen an increased number of exclusive designs that join a strong heritage of standard washers, including a combination of geometries and performances – all united by the aim to provide safer and more efficient solutions.

From development to production, from treatments to quality control, Growermetal’s manufacturing system has been structured to meet customers’ expectations in terms of performance, efficiency and safety in every application.

Alongside its production capabilities, Growermetal SpA is also able to supply a wide range of solutions, with its expanding portfolio of washers helping establish Growermetal’s name in the national and international markets.

With more than 7,000 items produced, divided into washers and special parts according to customers’ specifications, the range offers many features – such as high resistance to loosening in the presence of vibrations, dynamic loads, heat, temperature and other challenging conditions.

In terms of functions and industries, Growermetal’s products makes it a trusted supplier for the automotive, railway and aerospace sectors, and many other application fields.

During the last decade, Growermetal’s investments have been focused on updating the production model through advanced machines and R&D projects. Today, the company is exploring new ways to safety, by combining the standard washers of its historical heritage with new designs – an approach that has led to a branded line characterised by exclusive geometries.

Grower TenKeep®: Differentiated surfaces, unparalleled lock

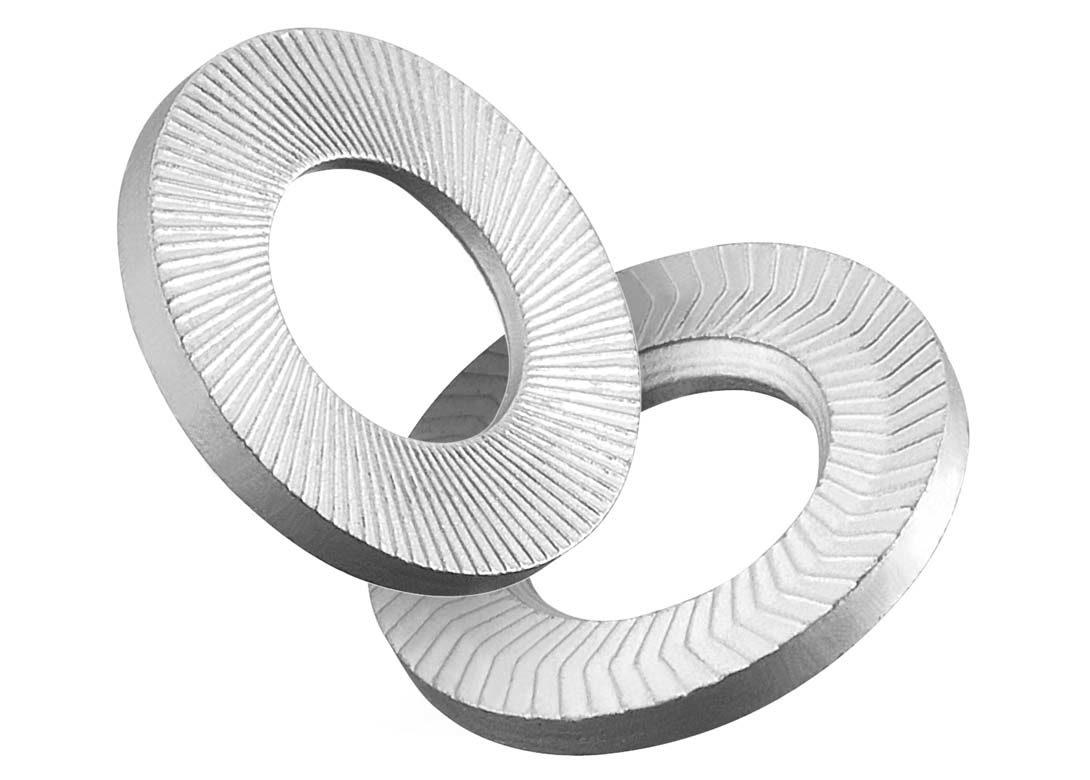

Grower TenKeep® is not only the first branded washer manufactured by Growermetal, it is also an example of the new path undertaken by the company. Launched and awarded with 3rd place at the Route to Fastener Innovation Competition at Fastener Fair Global in 2019, Grower TenKeep® is the result of hundreds of different geometries tested by the R&D team, with the objective to provide the maximum performance against loosening of the bolted joints.

The result is a safety washer with two differentiated sides, where ‘Side A’ is in direct contact with the head of the screw or nut and ‘Side B’ touches the bearing surface. The two work in combination, whenever ‘Side A’ prevents the loosening of the bolted joint connection, the particular knurling of ‘Side B’ remains solid to the bearing surface without damaging it, thanks to the exceptional grip. In addition, the chamfer on the hole that characterises ‘Side A’ helps the user to orientate the washer correctly.

The different tests, which included the so-called ‘Helicopter test’, proved the washer to be successful even when subjected to dynamic loads or in the presence of severe vibrations – typical of railway and infrastructure applications. Consequently, the performance of Grower TenKeep® is durable, with a high mechanical resistance and a very good level of untightening torque in comparison to the tightening torque.

The preassembled set of Grower SpheraTech®

After being amongst the winners for the 2019 edition of the Route to Fastener Innovation Competition, Growermetal was again a winner during the 2023 edition at Fastener Fair Global for its Grower SpheraTech®.

This product is the combination of a spherical top washer and a conical seat washer, which are among the most common locking technologies of the fastener sector. Where does the innovation of this product lie? One of the potential problems related to the use of similar products is washer loss, which is why Growermetal’s team created the permanent assembly of the two parts – eliminating the risk of incorrect mounting and part loss during application.

In addition, Grower SpheraTech® facilitates the assembly while providing the same function of the traditional products, locking uneven or non-parallel bearing surfaces through the compensation of the angle of inclination. Thanks to the pieces coupling, it is possible to reach a superior locking function and preserve the bolted joint connection from damages or breakages – caused by the bending of the head or the shank of the screw.

New products to face every challenge

Recently, Growermetal has added a series of new washer solutions that integrated into the wide portfolio of standard products. Developed by the company’s engineers, thanks to investments in R&D projects, the line includes cutting edge fastening systems.

An example are the high thickness and precision flat washers, which are particularly suitable and widely used in the automotive industry. These special products are engineered and manufactured by the company according to customers’ technical specifications and drawings, to guarantee the best performance for different applications.

Together with these washers, another innovation is constituted by metallic pieces with EPDM inserts. Through the integration of the EPDM elastomer in the composition, the parts benefit from a great resistance to extreme outdoor conditions or high temperatures, as well as an improved compression performance. Growermetal is therefore able to develop and design moulded part projects, where the washer and the EPDM part are co-stamped or glued, with a remarkable improvement of performance

during application.

Finally, in order to boost the flexibility of its offer, Growermetal has specialised in the production of special blanked and bended parts, entirely designed, manufactured and engineered in-house by experienced technicians – following customer specifications. This service leads to the maximum customisation possible of the parts, in-line with demanding applications and the company’s aim to provide the most effective fastening solutions in the market.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.