To ensure they can meet deadlines and deliver products in-line with customers’ high expectations, UK manufacturers are looking for ways to increase assembly speed. Here Justin Lawrence, applications engineer at fastening and supply chain expert TFC Ltd, explains how to reliably speed up fluid transfer, a common assembly process in UK manufacturing.

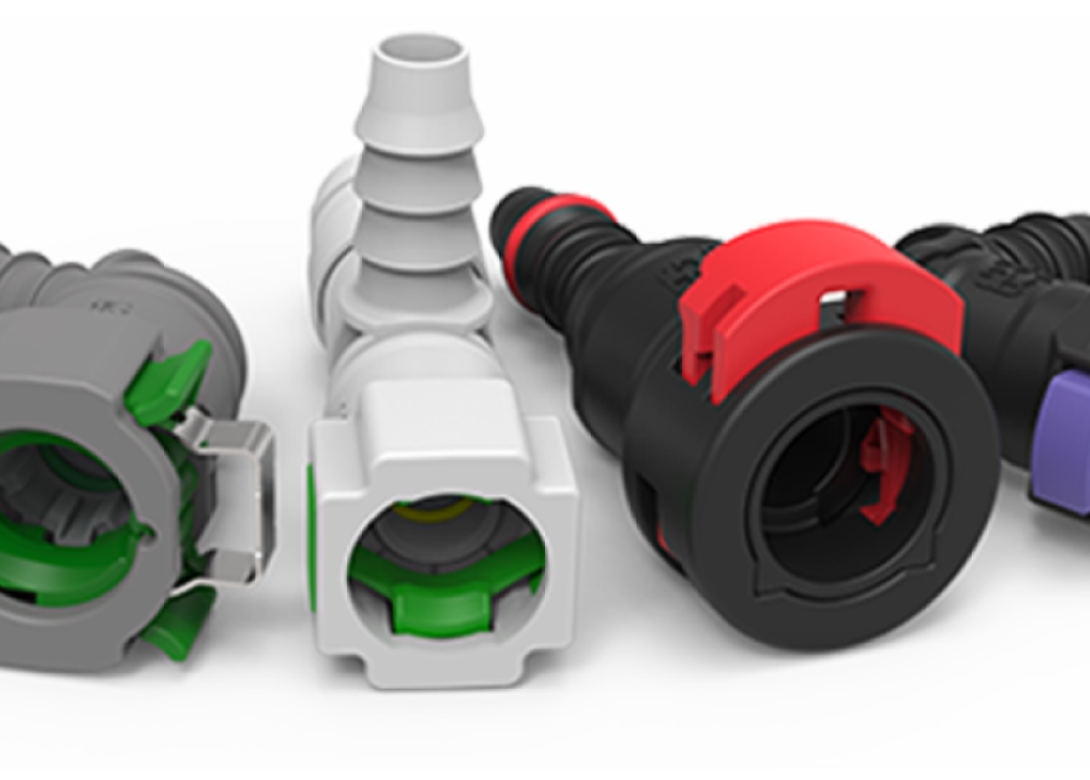

Specialist connectors are found in all types of automotive and heavy vehicle connection systems such as fuel lines, cooling circuits, selective catalytic reduction urea lines, battery cooling, air conditioning, power steering and brake fluid circuits. The most important factor when choosing a connector is that they are matched to the operating conditions, including temperature, pressure, fluid and the environment, but they must also be lightweight and corrosion resistant.

But these factors alone will not determine whether the connection is high quality. It must, of course, be correctly assembled, which means the operator needs to be certain it is secure. With most connectors, like jubilee clips or worm clamps, there is no obvious indicator that the connection is secure. This means there is a risk of quality problems arising later on, such as fluid lines leaking. In addition, attaching the two parts together requires tooling, and importantly, time.

Thankfully, there is a simple solution. Opting for a quick connector, a component that the operator simply pushes into place and it locks itself, can speed the process up significantly. It also offers a visual or audio confirmation of the connection, which removes the risk of the fluid line not being correctly assembled.

The quick connector has been a huge success in the automotive and power generation markets — you’ll probably find them if you look under your car bonnet. However, industrial manufacturers in household appliances, heating and ventilation and air conditioning are yet to reap the rewards.

As well as looking at the components themselves, there may be supply chain issues slowing down an assembly process. Sticking with our earlier example, a quick connector could be a great way to speed things up - but only if the part is in stock.

For manufacturers looking for ways to ensure a steady supply of the fastening components they need, vendor managed inventory (VMI) means parts delivered on time and direct to line. With VMI, all ordering is done through one partner, which can reduce costs when procuring components, as well as remove the risk of running out of stock and facing long lead times. It is important to note that whilst speed is important, it should not come at the sacrifice of the quality or safety of the application. Checking your supplier’s quality credentials, experience and processes can help ensure that you get the best of both worlds.

TFC stocks ARaymond quick connectors in a wide range of configurations. Whatever geometry, O-ring material, locking mechanism, assembly check options, end piece types, diameters or functions you need, we can assist. All components can be supplied as part of a bespoke VMI solution, so you always have the parts you need at your fingertips.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.