Here Andrew Nuttall, European managing director at TR Fastenings, a Trifast plc company, outlines the importance of sustainability in the modern age and how TR Fastenings has made a shift in its focus to more sustainable methods on an international scale.

The Paris Agreement on climate change in 2015 initiated a change in attitude in dealing with greenhouse gas emissions. The objective was to respond to global climate change and ensure that rising global temperatures were reduced and controlled – with the aim of getting back to preindustrial levels.

Being a member of Trifast plc, ESG became a very important part of TR’s future strategy and a Sustainability Committee was formed. Members of that team came from key disciplines in the business to ensure all bases were covered, embracing the environmental, sustainability and governance elements. This culminated in Trifast’s Sustainability Report being published.

As managing director for TR in Europe, my focus has been on the company’s distribution sites in Norway, Sweden, Holland, Germany, Spain, Hungary, as well as the manufacturing facility in Italy. As part of a group transformation project, TR had already embarked on creating a ‘modern workplace’ environment. This involved enhancing the IT infrastructure, the décor and image of our offices, break out areas for staff to relax and lunch together and generally creating a pleasant working environment. All sites are air-conditioned and accredited to ISO14001 – the environmental management system.

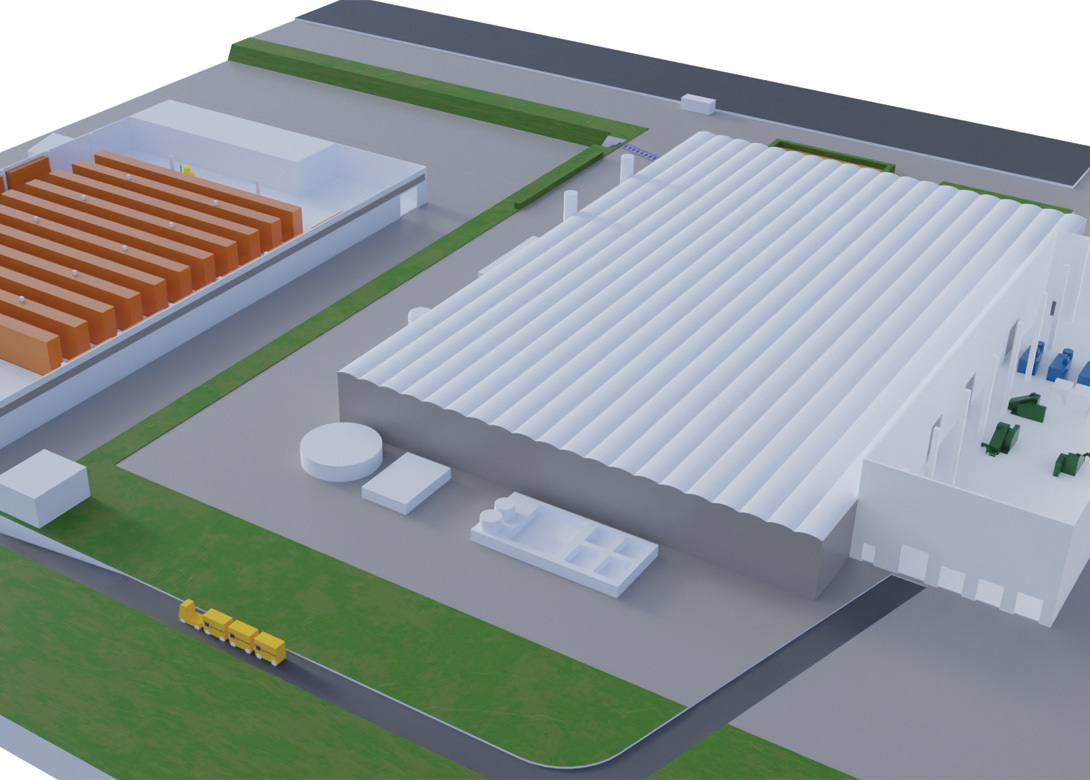

In 2022, the business embarked upon further expansion and opened a new distribution hub in Hungary to service that geographical area, and the seven countries on its border. A new greenfield site gave way to the most sustainable facility in the group.

The construction process included triple glazing, ensuring that working conditions were excellent and cost effective, even in cold winters and hot summers – with the furniture coming from sustainable sources. Solar panels and electric charging units were also included in the specification, and the air extraction filtration system throughout the building created a great working environment – meeting the building code regulations that the Hungarian government have mandated.

However, a manufacturing location the size of TR VIC in Italy is a wholly different proposition. This facility is located in Umbria and had been in private ownership for over 40 years until TR acquired it in 2014. This location has a long history of manufacturing high volume fasteners, working on developing products and creating innovative designs for the domestic appliance market.

Over the last five years, TR have invested heavily in creating a manufacturing facility that is ‘fit for the future’, creating a sustainable production facility for cold forging industrial fasteners. Customers’ needs and requirements have also changed over the last five years, as ESG is high on multinational agendas, and the reporting of CO2emissions is a key factor.

The Covid-19 pandemic also added another dimension as companies reassessed their dependence on Asia, with increased lead times and the disruption to supply chains that had been created. As a result, there has been a concerted drive by customers towards ‘near shore’ to reduce lead times; the high cost of transportation; and the need to be able to demonstrate CO2 reductions. However, we are still poised for further growth, as the desire for ‘near shore’ is gathering momentum.

Following the recent milestone for TR VIC in Italy – celebrating its 45th anniversary – the company saw an opportunity for further investment. A roll out program of refurbishment of the main manufacturing location began, along with investment in new Italian machinery – with TR were keen to diversify. Having gained the IATF 16949 accreditation a few years before, TR VIC was able to attract and secure business with major OEMs. As a result, the company invested in cold forging machines capable of making more complex and larger diameters, and in automatic packaging machinery.

This investment continued with a recently opened extension to the manufacturing floor space, creating an additional 33% capacity. New efficient ventilation systems and power plants within manufacturing have been installed and major changes to the finished goods warehouse have been completed. This included infrastructure changes as TR created a new road into the revamped and re-racked warehouse that are Microsoft D365 compliant and operate electric tugs between both buildings. The company has also experienced an increased number of successful automotive customer audits since the Covid-19 pandemic and a high percentage of new business wins have increased the sector diversification that TR anticipated following the IATF 16949 accreditation.

With a sustainability project team in TR VIC headed by Stefano Pisoni, managing director, TR have initiatives underway, including changes in the way products are cleaned after forging to reclaim the oil for reuse and eliminate waste. Most of the domestic appliance manufacturers prefer products in plastic woven sacks as these are easier to handle and tip into automatic feeders on the production line. TR are also working on alternative sack material that is organic and have two products currently on trial.

As I said in my earlier comments this is a journey not a destination and there is more work to be done, and we are fully committed to doing it.

www.trfastenings.com

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.