Quality is critical to the success of a manufacturing business. Even the most loyal customer will look for alternatives if their expectations aren’t met. Dedication to quality starts with the smallest components, often the most overlooked and inexpensive – fasteners. Here, global fastener manufacturer Optimas OE Solutions gives a list of things to look for in manufacturing engineered fasteners.

Fasteners are one of the most important components in product design. By investing in the right high-quality fasteners up front, risks can be reduced, performance and efficiency can be optimised, as well as improving costs while ensuring product reliability and positively impacting revenue and brand reputation.

The fastener manufacturer and engineers chosen to produce a product’s fasteners should be an extension of the team and capture a company’s culture. By getting them involved from the start, stating expectations up front, asking the right questions about production processes, and keeping communication lines open, a quality end product is all but ensured.

But what makes for a high-quality fastener? There isn’t one right answer - it’s a combination of criteria that ensures a fastener manufacturer and engineering partner are delivering the best quality components for a business.

In-house expertise - proof of high-quality fasteners begins with the first conversation with a fastener manufacturer. Do they have the knowledge and expertise to do the job? Are they someone you can trust with your new or existing product design? Look for a fastener manufacturer partner with specialised engineering teams and decades of knowledge both on the application design side and within fastener manufacturing. With this level of experience and backing, you can be more confident in the products you bring to market.

Design knowledge - involve your integrated fastener engineering/manufacturer partner early in the project. While they can help at any stage of production, you’ll gain the most benefit in the design stage. Many experienced fastener manufacturing engineers have worked with dozens of manufacturers on different projects across a wide array of industries. Their diverse experience equips them to bring new ideas to the table or identify pitfalls in the existing design.

Safety and reliability - once you’ve selected a team and begun to develop a design, safety and reliability become top priorities. Be sure to have conversations with your fastener manufacturing engineers and underscore the range of conditions the final product may endure. Extreme heat, extreme cold and regular vibrations or movement can all compromise safety standards and fastener weaknesses become harder to identify or fix the farther you get along in production. An engineering partner capable of producing high-fastener engineering partner capable of producing high-quality fasteners should be able to take that knowledge and create customised solutions to ensure any risk to the product and your customers is minimised.

Testing and prototyping - expertise and knowledge will only get you so far without the ability to put those ideas to the test. Look for an integrated fastener engineering/manufacturer with the capability of testing your products and prototyping new parts prior to production. Having a tangible model can help you navigate uncertainties, detect problems and develop innovative new solutions without costing your company too much on the front end. 3D print capabilities and access to advanced technology is often a sign of a partner that can deliver high-quality products.

Materials - where do the materials you use come from? This is a question many customers never ask but should. As you work with fastener manufacturers, ask about how they source their materials, what materials they use, and why they chose them for customized projects. Going back to the importance of in-house expertise, the more knowledgeable a team is about materials being used, the more likely they are to target quality over cutting corners.

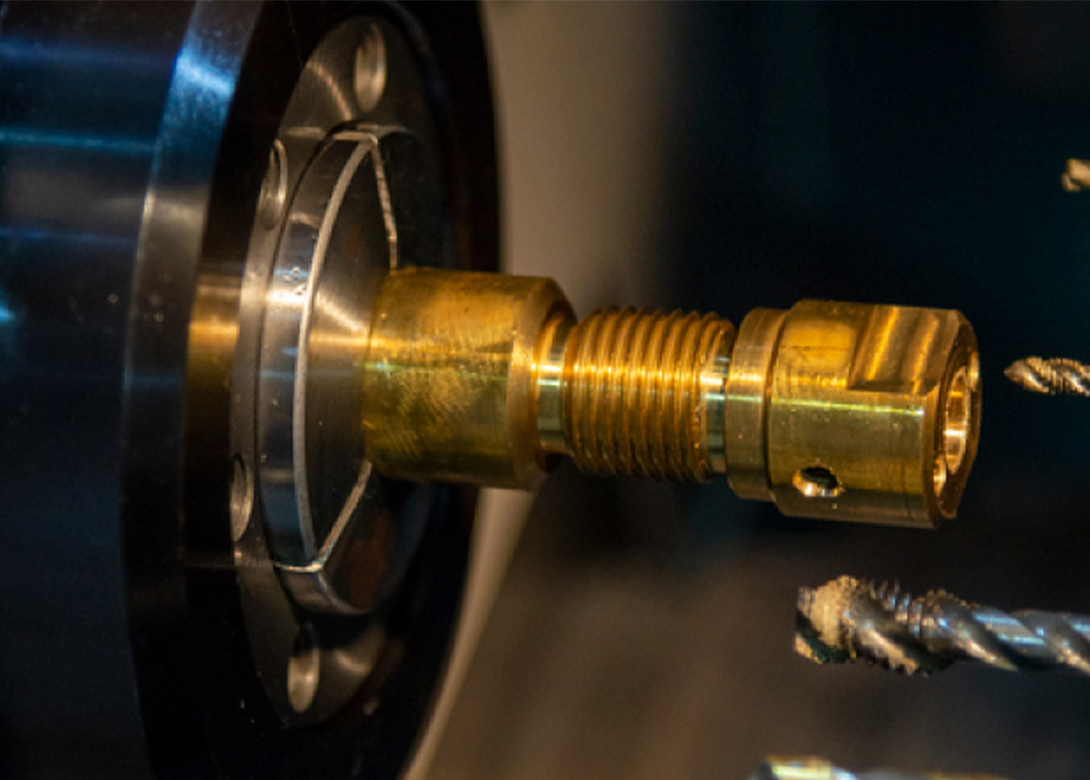

Equipment - when we discuss customised fasteners with customers, the first thing we have to understand is whether we have the equipment in place to produce the part correctly. Remember to tour the production facility and ask if they are producing the tooling in-house or out-sourcing it. Reduced equipment capability in-house could result in higher costs, longer lead times and a greater likelihood that someone might try to take a shortcut that saves pennies today but costs dollars down the road.

24/7 customer service - finally, caring about fastener quality shouldn’t stop when the components ship out. At Optimas, we provide 24/7 customer service and are on-hand to assist whenever customers have questions. When defects occur or if redesigns are required, you should have access to a solutions provider with a text, phone call or e-mail. Look at how your selected team works with customers before, during and after production and make sure you have ways to get in touch with them once your fasteners are out the door.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.