With over 30 years of providing effective bolt securing systems to the world, the Nord-Lock Group is now a more vibrant global operation than ever. Combining three technologies and companies into one connected Group has enabled Nord-Lock to offer a broad product range, with a unique global knowledge package.

The development of Nord-Lock Group as it is today comes from a focus on the knowledge offering, to meet customer requirements and to create one common goal of being a true solution provider. “We recognised that there was an opportunity to further strengthen our offer and the value we can bring,” says Graham Souter, sales director for the European region. “It was around 15 years ago when Nord-Lock Ltd joined amongst others Nord-Lock Inc as fully owned subsidiaries and that acted as a starting point of the company becoming the international group it is today. Since then we have continued to grow our organisation in more territories and this has been an important part of growing key relationships and bringing value both to our customers and our partners.”

Three great stories

The range of expertise that Nord-Lock Group now has at its disposal is neatly summed up in the stories of the technologies, and the knowledge vested in the people behind these technologies. This expertise perfectly complements the origin of the Nord-Lock offering.

The Nord-Lock story began back in 1982 when the company started to develop what was to become the world renowned Nord-Lock washers. Nord-Lock washers are produced at a truly focused site in the remote parts of northern Sweden. “The products we manufacture are to be used where failure is not an option,” says Kurt Persson, senior advisor at Nord-Lock. “Developing these wedge-locking products with the customers’ application in mind makes us different. It has allowed us to excel at finding ways to help our customers and we continue to perfect it.”

The Superbolt trademark dates back to the 1970s in the steel city of Pittsburgh, USA. It was a man named Rolf Steinbock who revolutionised the principle of jackbolts by replacing conventional nuts and bolts with multi-jackbolt tensioners. In the process, this eliminated many common bolting problems experienced by heavy industry in the area. The business grew with an additional site in St Gallenkappel, Switzerland, as more industries realised the huge advantages of the solution. The similarities to Nord-Lock were many – being the original developer of the technology, having a strong focus on finding solutions even for the most challenging conditions, and offering highly focused project engineering skills.

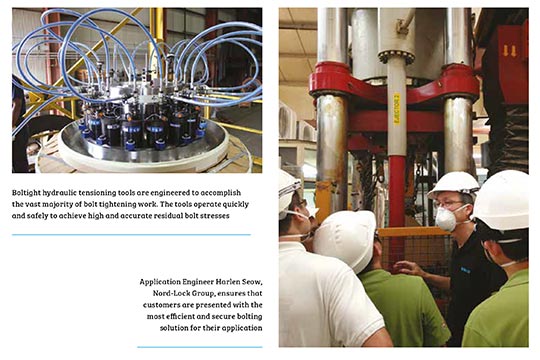

The story of Boltight was initially the story of Fred Heaton, who was involved when the technology of hydraulic tensioning was first developed near Birmingham, in the UK. In 1999 Fred started Boltight and, together with a focused team, developed hydraulic bolt tensioning tools that are lightweight, compact and easy to use, and which are now used globally on numerous industrial applications. With long experience in meeting their customers’ requirements with state-of-the-art hydraulic tensioning, Nord-Lock Group had once again found a match for expanding the total offering.

Product innovation – with safety in mind

According to Andreas Maile, managing director of Nord-Lock Germany, the broadened product range is key in the development. “We are in a niche market where we need to have competence, experts and educated people,” he says. “Different industries demand different priorities, and having multiple product lines that meet the demands of the toughest applications is essential. Take product maintenance on a wind farm for example or providing bolting solutions for acidic environments or extreme heat.”

Andreas continues: “The industries we serve are fast-developing and it is important to stay close to our customers, working together in these knowledge partnerships is vital for the mutual benefit and as the portfolio grows we can always find the right solution to any challenge.”

The product range offered by Nord-Lock Group reflects a portfolio in tune with the modern marketplace. The bolting solutions are available in the widest range of materials and sizes. It has often taken additional steps from the original technology, such as the multifunctional wedge-locking technology of the X-series washers and the radial sleeve incorporated in Superbolt Expansion bolts.

“Wedge-locking washers are the origin of our company,” Graham Souter says. “Both mechanical and hydraulic tensioning systems have their own strong advantages, so by offering the flexibility afforded by the additions of our Superbolt and Boltight solutions, we are able to meet our customers’ challenges head-on and deliver a complete package as required.”

With bolting solutions from Nord-Lock Group being fitted on millions of applications worldwide, the safety aspect is of upmost importance. The Nord-Lock Group is involved in spreading bolting knowledge on a daily basis, offering both on-site and remote support, combined with the technical verification carried out from in-house laboratories to ensure secure and optimised solutions for its customer base.

Serving the global market

Serving the global market

Maximising customer uptime in today’s market means offering a competitive solution for the customer over the whole operational life cycle. To prove the long-term economic advantages of applying the optimum technology to an application is valuable, and customers recognise the benefit of the partnership.

Distribution centres in North America, Europe and Asia supply products from Nord-Lock Group to a network of authorised partners. According to Graham, cooperation with the distribution network is crucial in serving the global market. “We have dedicated resellers in every country within Europe and a long list covering the global network,” he says. “Our specialised offers require different relationships. We have trusting relationships with our global distribution partners, which is important – especially for Nord-Lock wedge-locking solutions, since they are commonly sourced together with standard fasteners. As a manufacturer with a strong engineering resource, the trust built up with our distribution partners is what enables us to together bring a superior and effective offer to the customers. We work with our partners for the benefits of our users. Across our product range it is the technical link we hold with engineering departments that is a driver of the interest in our products and we continue to develop these relationships by providing strong technical input.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.