For over 20 years, specialist adhesives and equipment expert Chemique Adhesives has helped leading UK furniture manufacturer, Boss Design to produce innovative, high-quality products and solutions that boasts the many attributes of British engineering, craftsmanship and cutting edge design.

Chemique Adhesives has always been committed to providing its customers with advice and expertise and from this have established a strong relationship with Boss Design, by being its sole supplier of adhesives and application equipment. During the past two decades that both companies have been working together, Boss Design’s needs have grown, and Chemique Adhesives expertise has always been equal to addressing the challenges faced.

Initially, Chemique supplied Boss Design with a low solids, solvent based adhesive but as water-based adhesive technology evolved, the company was able to help Boss Design to make the switch from solvent-based adhesives.

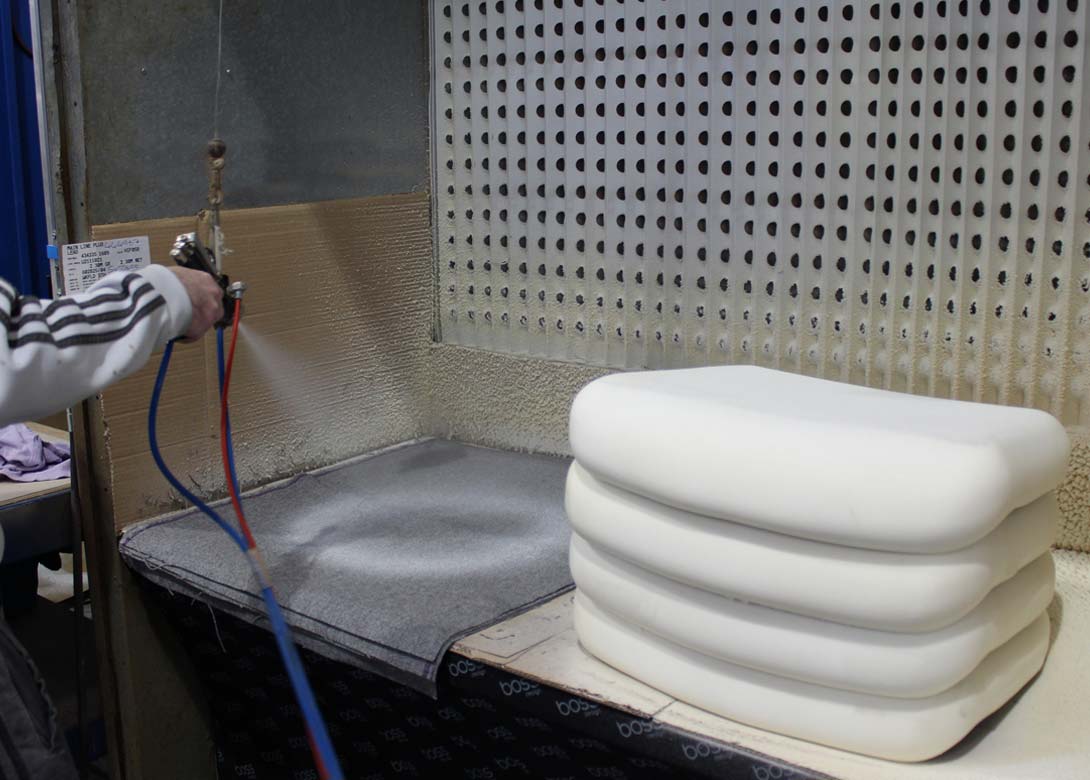

“ProAqua 2 is a high performance, user-friendly alternative to a solvent-based adhesive, that allows for a better manufacturing and application process, as well as a safer working environment,” said James Thorpe, Chemique adhesives sales manager.

“Our ProAqua two-part water-based adhesives are unique in that they offer excellent adhesion to the complete range of substrates used by Boss Design including moulded and cut foams, a range of fabrics, wood and of course, where most struggle, plastics. The bond to plastics when using ProAqua 2 is second to none in the UK and has helped Boss Design win coveted contracts where their clients insist on non-hazardous materials being used”.

ProAqua 2 provides excellent tack even on difficult substrates and another advantage is that there is no fabric bleed through so there is no need for retouching and cleaning after application. Chemique also installed a state of the art adhesive metering system and recirculating extraction system, providing a safer, healthier option that eliminated the need to vent to the atmosphere.

Boss Design was one of the first UK based office furniture companies to successfully switch from solvents and today, the majority of Chemique’s customers within this sector are using one of their water-based adhesives. Over the years as Boss Design has grown, it has moved to larger premises and each move has involved Chemique’s engineering team, who have dismantled and rebuilt spray booths and equipment as well as making any necessary upgrades.

Of course, Chemique’s renowned ‘Total Service Package’ provides Boss Design with total peace of mind as equipment is regularly serviced and any breakdowns that may occur are dealt with quickly and efficiently reducing any down time and as well as this, are always available to deal with any queries that may arise.

The quality of the adhesives provided by Chemique has meant that over the last twenty years Boss Design has never had an adhesive related complaint on any chair that has been made. Dave Smith explained “The quality of the products and service supplied by Chemique means that I have one less thing to worry about, safe in the knowledge that I have the best adhesives available today and that any breakdown issues are quickly resolved.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.