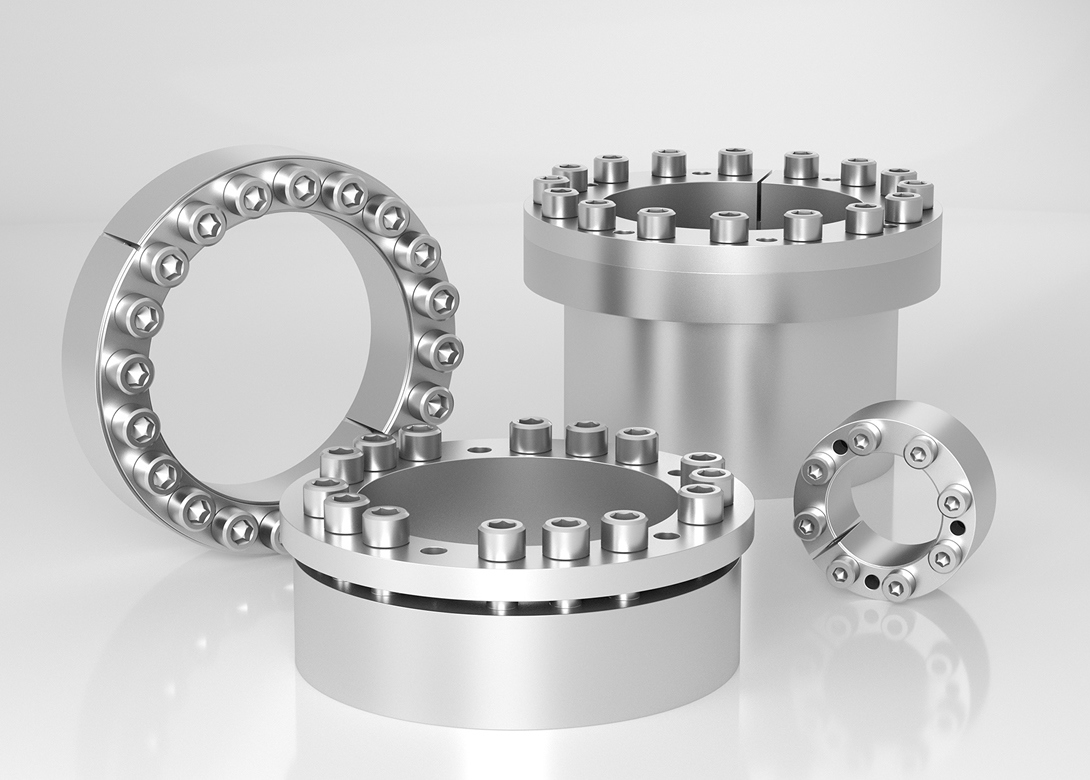

Fastener developer and manufacturer BUMAX has supplied more than 80,000 screws to RINGFEDER POWER TRANSMISSION in the course of 2020. The fasteners have been installed in more than 7,000 new RINGFEDER shaft hub connections around the world.

RINGFEDER POWER TRANSMISSION is a long-standing customer of BUMAX that has used high-strength corrosion resistant BUMAX stainless steel screws since 2012 as they are able to transmit high torques with the company’s rust-proof locking devices.

“BUMAX was the only company that could provide the high strength fasteners with the corrosion resistance we required for our applications,” said Rainer Peter, senior product manager for shaft-hub connections at RINGFEDER POWER TRANSMISSION.

A German-based company, RINGFEDER POWER TRANSMISSION primarily uses BUMAX 109 to provide the necessary strength and corrosion resistance for its demanding applications. The company offers users worldwide superior shaft hub connections, damping solutions and coupling systems for the highest functionality and durability requirements in a wide variety of industries.

“The unique advantage of BUMAX 109 is its high strength, which means that we achieve the same transmission values with our rust-proof shrink discs as our standard shrink discs with screws of quality 10.9,” concludes Peter.

In 2016, RINGFEDER POWER TRANSMISSION also began using BUMAX DX 129 screws for some of its products. BUMAX DX 129 is the ultimate choice for applications where very high strength, ductility and corrosion resistance are required. It offers around 20% higher strength than BUMAX 109 and a very high level of corrosion protection.

RINGFEDER rust-proof locking devices are used as standard in gearboxes and pumps and other machines around the world. The products are used by pharmaceutical companies, the food and beverage industry, in geothermal and hydropower power plants, ship drives and packaging machines.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.