Schunk Sonosystems, a leading specialist in the field of ultrasonic metal welding, has recently selected BUMAX to provide fasteners for us in ultrasonic metal welding machines.

BUMAX DX 129 screws were selected by Schunk Sonosystems for all its ultrasonic welding flexure sonotrode products to further improve quality and reliability – machines which are mainly used in the automotive industry. The BUMAX DX 129, manufactured from Duplex stainless steel, offer very high tensile strength – a minimum of 1,200 MPa as well as high fatigue resistance properties. The fastening deals with the with extreme forces during the ultrasonic welding process, such as 20,000 vibrations per second.

Ultrasonic welding is a solid-state welding process that uses ultrasonic vibrations to weld pieces of metal together. The metals are welded together by heat generated by friction when applying high-frequency ultrasonic vibrational energy.

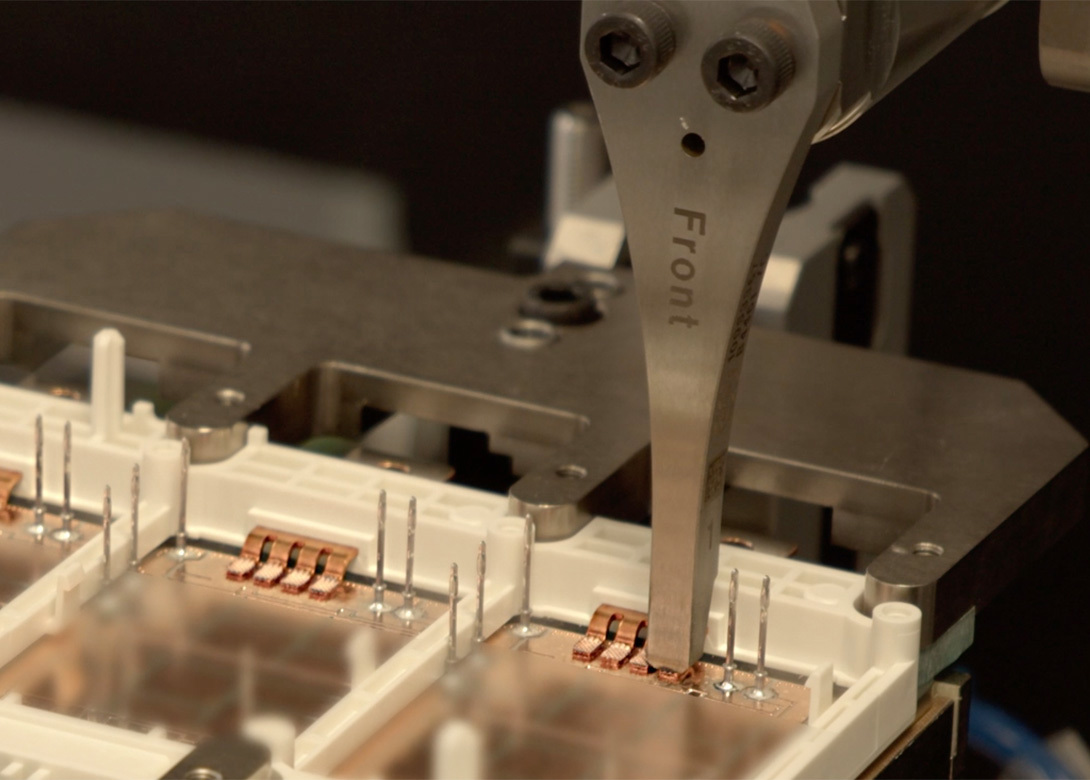

Schunk Sonosystems’s machines include a sonotrode or welding tip that transfers vibrational energy to the workpiece. Up to two high-strength bolts are required to fix the sonotrode, which is subject to extreme levels of vibration due to the very high frequency used in ultrasonic welding.

“Standard steel bolts simply cannot cope with the extreme pulling and bending forces of ultrasonic vibration, so we had to find a bolt that does,” said Stefan Mueller, head of R&D at Schunk Sonosystems. “Of all the screws we tested, only BUMAX met all our needs. Not only are BUMAX consistent in how they perform and do not break, they last the lifetime of the sonotrode without problem. They don’t create abrasion dust on the screw head or require rust protection.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.