It’s been known for over 50 years that if movement of joint plates occurs, the securing bolts can self-loosen. Here, Dr Bill Eccles of Bolt Science outlines the vitality of preventing joint slipping and bolt self-loosening.

The research completed, first by Gerald Junker and followed by many subsequent researchers, found that if transverse joint slip occurs, simultaneous slippage of the bolt head, or nut face, and the thread interface, momentarily frees the fastener from friction. Free from the restraints of friction, the load present in the bolt, acting on the inclined plane of the thread, allows the bolt to rotate by a small increment. Recurring joint movement repeats this self-loosening process until the bolt is completely relieved of its load.

The speed in which the bolt can loosen depends upon the magnitude of the joint movement, the fastener friction, and the grip length of the bolt. If you prevent the threads from slipping, by use perhaps of an adhesive, or the head from rotating by for instance a wedge-lock washer, self-loosening will not occur.

With a non-locked fastener, when a transverse load is applied to a joint that is too high to be resisted by the friction grip provided by the bolts, the joint interface will slip. The thread interface and the bolt head need not immediately slip since it will be resisted by the friction grip from the bolt load. The bolt will bend slightly to resist the forces. If the force continues to increase, joint movement will continue. As the joint displaces further, the force being applied to the bolt, because of its bending resistance, increases. A critical point is reached that is above the friction grip capacity from the bolt load, at this point, thread and head slip is initiated. Loosening then occurs when the bolt head, or nut, slips on the joint surface.

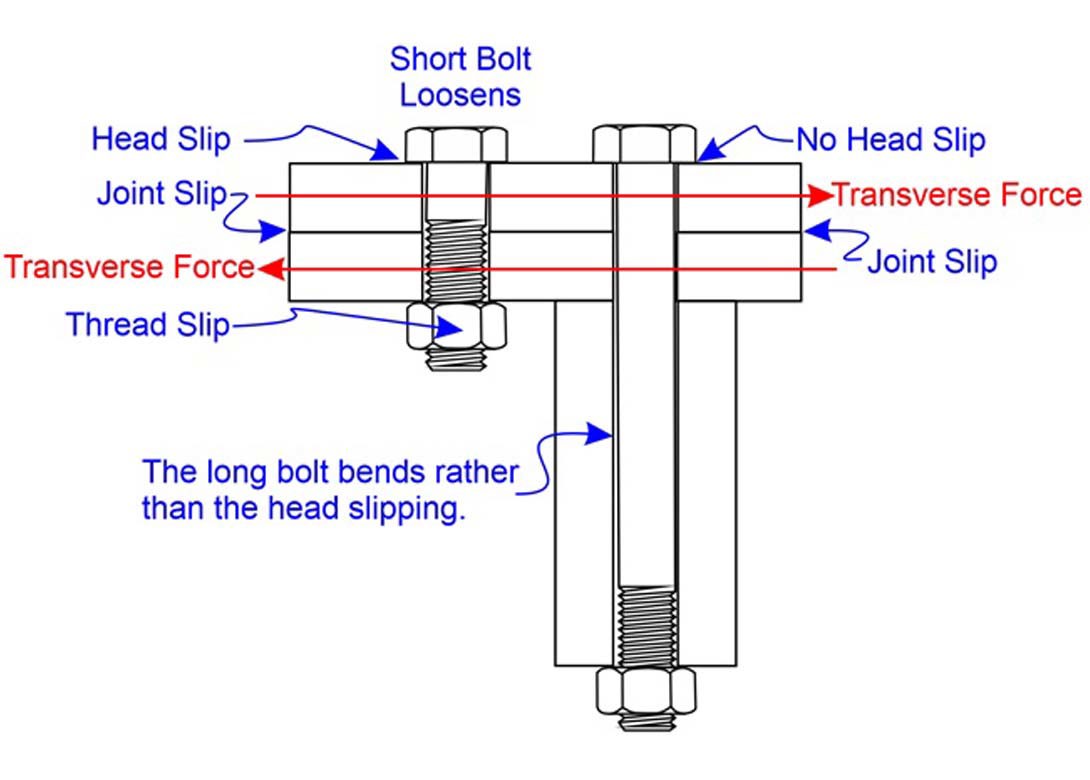

Long grip length bolts are inherently more resistant to loosening than short bolts. This is illustrated in the image. Under small transverse joint movements, the bolt will bend rather than suffering slip of the head or thread bearing surfaces. The amount of joint movement needed to initiate slip of the bolt bearing surface is referred to as the ‘critical slip distance’. Hence a short grip length bolt may have a critical slip distance of less than 0.1mm whereas a long grip length bolt it may be 0.5mm or more. Hence if the joint movement is limited in this case to 0.2mm, the short grip length bolt would loosen whereas the long bolt wouldn’t. The side of the hole would touch the bolt shank and transmit shear load by direct contact. Close fit clearance holes can be used so that the amount of joint movement is restricted so that the wall of the hole hits the shank before head or thread slip occurs.

If loosening is prevented by use of a locking method, or a long grip length is used, the bolt sustains bending stresses due to the friction grip from the bolt load acting on the head/nut. If the joint movement is frequently repeated, then fatigue failure of the bolt becomes likely. A standard test for assessing the loosening resistance of a fastener is a Junker test. This measures the bolt load as the joint that the bolt clamps are repeatably subjected to transverse movement.

If a locking method, such as a wedge-lock washer, is tested on such a machine, self-loosening does not occur. Typically, the fastener is tested for 1,000 cycles or so and if no significant loosening occurs then it is assessed as being resistant to self-loosening. If the machine continues to operate, what is typically found is that after 3,000 cycles or so, the bolt load starts to reduce as a fatigue crack propagates through the bolt until it fractures completely. Bolt loosening is a short term consequence of transverse joint movement and fatigue, a longer term consequence.

Due to its lower bending stiffness, a long bolt will sustain less bending stress than a short bolt with a locking method applied. Consequently, in applications where repeated joint movement cannot be prevented, long grip length bolts can offer some design advantage.

www.boltscience.com

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.