Here Dr Bill Eccles, from Bolt Science, discusses how if several bolts of the same size are tightened by the same method, there will still be variation in the preloads of each bolt as they won't all have the same value.

This variation is influenced by a multitude of factors, such as variation in friction characteristics in the thread and under the nut face, thread form and pitch variations, or variations in the surface flatness. Hence for any particular tightening method, there will be a maximum anticipated preload and a minimum given to a set of conditions.

The tightening factor is a measure of the scatter in a bolt's clamp force, as a result of the tightening method used to tighten the fastener. It is defined as the maximum bolt clamp force divided by the minimum value anticipated for that tightening method. For tightening with a torque wrench the tightening factor is usually taken as 1.6 – where the maximum preload value is 1.6 times the minimum.

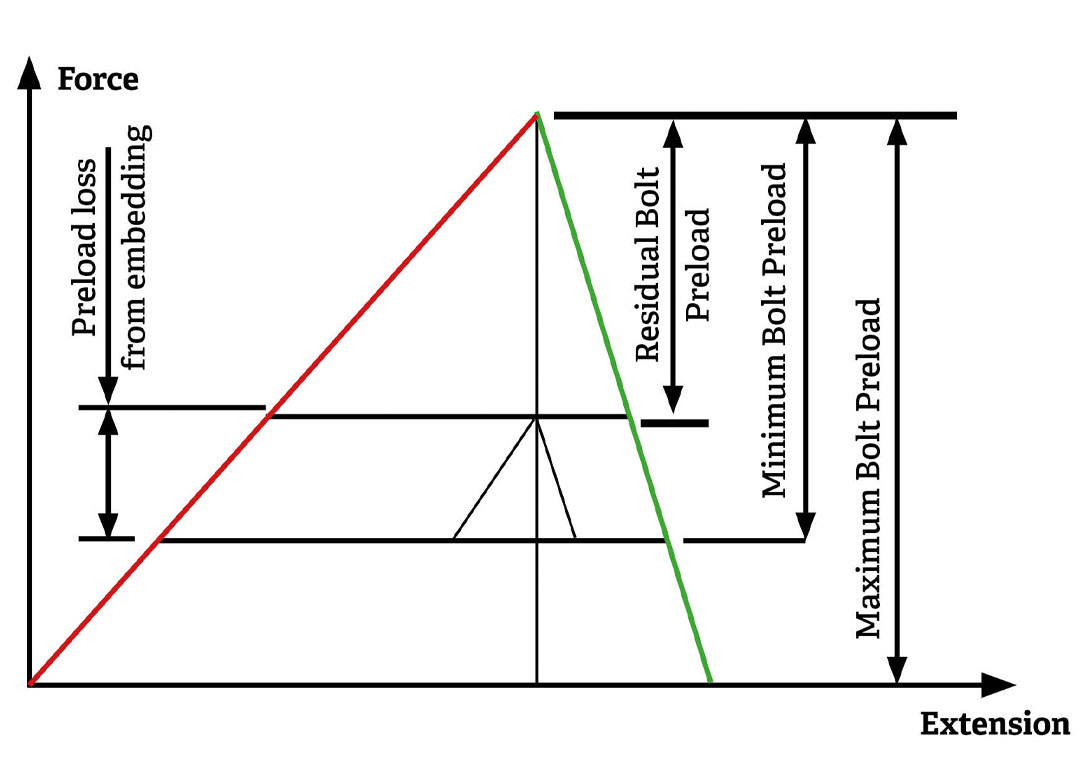

A joint diagram showing the effect of preload variation and embedding is shown here. Since the bolt is not to be broken by overtightening on assembly, it must be selected for the maximum initial preload. Hence for a given bolt size, the smaller the tightening factor, the larger the residual preload is remaining to sustain the applied forces to the joint.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.