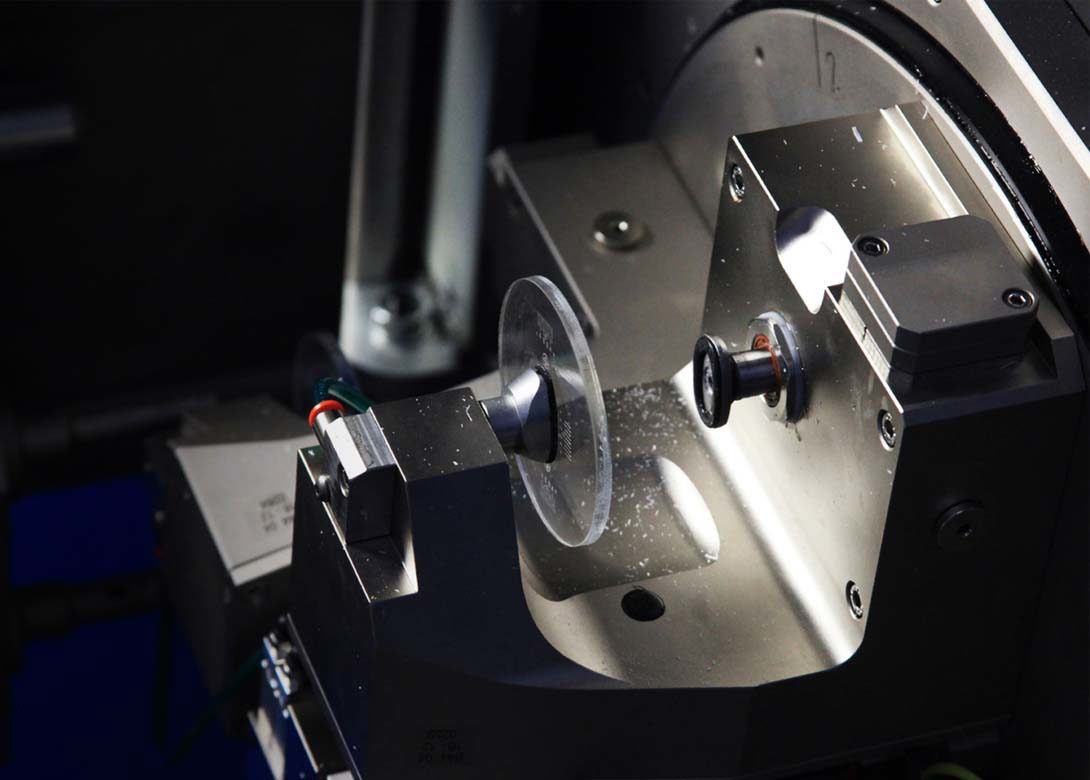

Since the 2000s, Italian-based MEI System changed the production processes used in the optics sector through the use of its machines. Here, the company explains how its utilising NSK ball screws in its lens cutting machines.

MEI manufactures its machines in-house, using various suppliers for the main components including NSK for the ball screws. These ball screws help to guarantee precision and fluidity of movement and make the machines capable of performing top quality milling on the various materials used to make lenses.

"Our technical department recognises the NSK brand as a reference point for linear motion components, and our long-standing relationship testifies to the absolute quality of the products offered by the Japanese multinational,” says Daniel Ponti, global operations director of MEI Systems.

"In the case of construction ophthalmic lenses, the milling quality and precision requirements are even more extreme, with very tight tolerances, as even the slightest imperfection in shape would negatively affect the quality of vision. For these projects our engineers also use NSK ball screws to transform rotary motion into rectilinear movement, ensuring maximum positioning accuracy,” adds Mr Ponti.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.