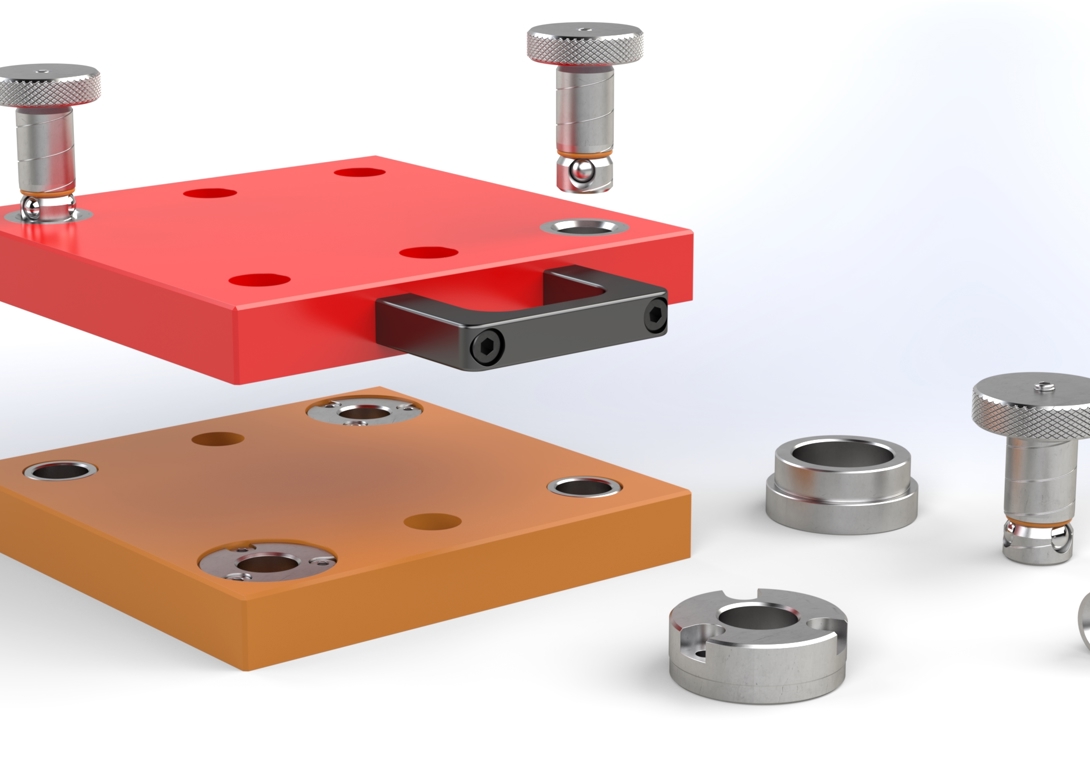

Standard parts and components supplier, WDS Components Ltd has released a stainless steel version of its ball lock mechanism. The new product line provides extra durability and rust-free use for the accurate locating and locking of fixture plates and subplates to machines.

The ball lock mounting system ensures repeatable positioning, reducing set-up time and making secure installation of plates to machinery both fast and simple. Accuracy of positioning means the installer doesn’t have to make an extended check of fitting, reducing overall installation time. The advantage of the ball lock compared to using dowel pins is a result of its location and pull down fastening mechanism, providing greater accuracy and security.

The device consists of a locating shank as well as liner and receiver bushings. The receiver bushings are installed into the machine or subplate with the liner bushing inserted into the fixture plate. The locating shank is then inserted through the liner and into the receiver where tightening the shank’s grub screw establishes the required holding force.

Ball locks are regularly specified by end user fixture designers aiming to improve or secure OEM-supplied machinery, as well as machine builders using the fastening devices at source. The advantage of the new stainless steel ball lock mechanisms is their resistance to corrosion, even in aggressive environments.

Stainless steel ball lock shanks and bushes will remain rust-free over prolonged use with corrosive media, ensuring longer machine life and improved maintenance procedures. The ball lock shanks, which are removed and act as installation tools, are available in 12 sizes, while the liner bushes are available in 33 sizes. Reverse mount bushes are also available as well as a version with recesses, which can be bolted to the plates. The ball lock shank also has an optional repair kit available, consisting of replacement bearings and an O-ring, which helps keep down maintenance costs.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.