norelem’s range of ball lock pins provide added reassurance to engineers where dependable high shear strength is most needed.

The ball lock pin has a practical locking mechanism designed for quick release in numerous applications. When the button is pressed, it activates the spring mechanism inside the pin which releases the ball lock by withdrawing the balls within the part. Once the button is released, the ball lock is activated again which guarantees a stable and self-securing locking function.

The component’s efficient self-locking mechanism significantly reduces set-up time, providing engineers with connections that are quick and easy to join. norelem’s ball lock pins have been designed for use in multiple applications, ranging from automation technology, robotics, electronics and processing mechanics to machine and plant construction.

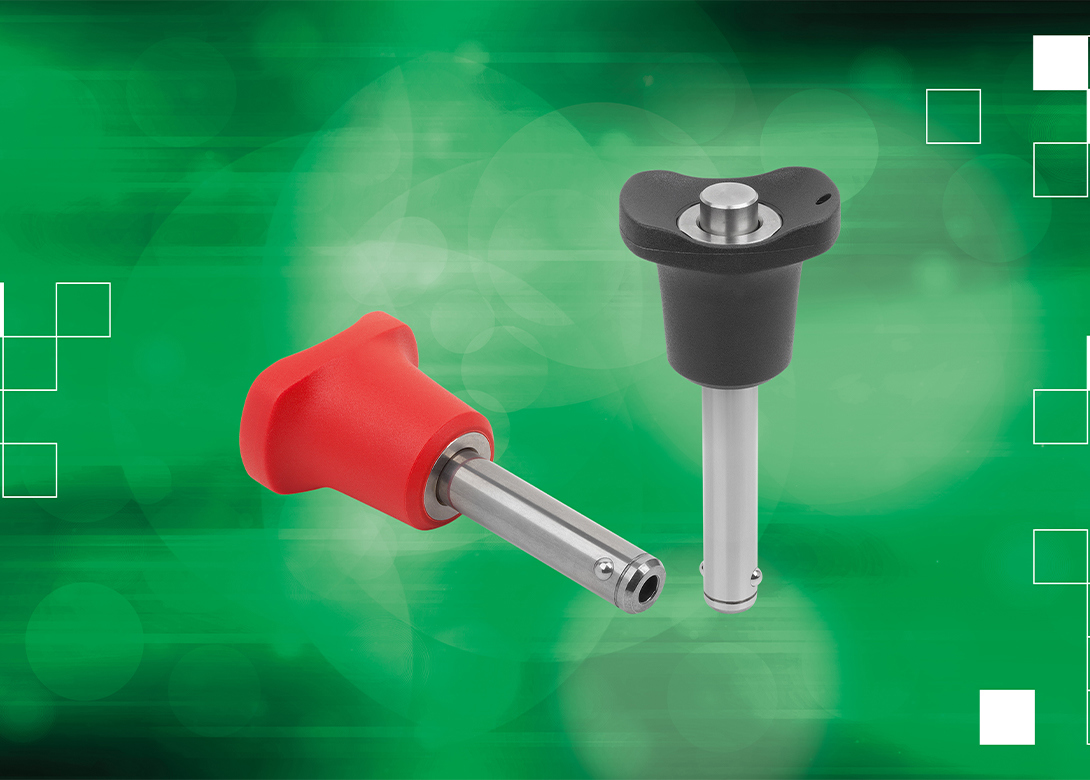

norelem’s ball lock pins are available with a normal grip, T-grip or L-grip depending on the application, with diameters from 5mm to 16mm. Length sizes range from 10mm to 80mm and shearing forces from 24kN to 257kN, enabling engineers to choose the perfect fit for the job.

With higher loading potential than standard ball lock pins, norelem’s ball lock pins not only provide higher shear resistance but notable durability, ensuring the component can withstand heavy and frequent usage. This is achieved by utilising high-grade materials throughout the part’s mechanism. The initial grip is made out of thermoplastic, which is then supplemented by a stainless steel 1.4542 pin and stainless steel 1.4305 push button alongside a spring mechanism (1.4310 stainless steel) and the ball component itself (1.4125 stainless steel).

To ensure load specifications are accurate, all load values have been calculated following DIN 50141 as standard to provide engineers with the information needed to make an informed decision for the respective application.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.