In October 2021, Henkel Adhesive Technologies, part of the Henkel Group, introduced LOCTITE Pulse, an industrial IoT (Internet of Things) solution that ensures the reliability of critical assets. Once installed, the sensors continuously collect data and provide insight into asset health.

The LOCTITE Pulse solutions have been installed in several Henkel plants, such as the Persil and Pritt production plants, as well as in the recently finalised Henkel Adhesive Inspiration Centre Düsseldorf.

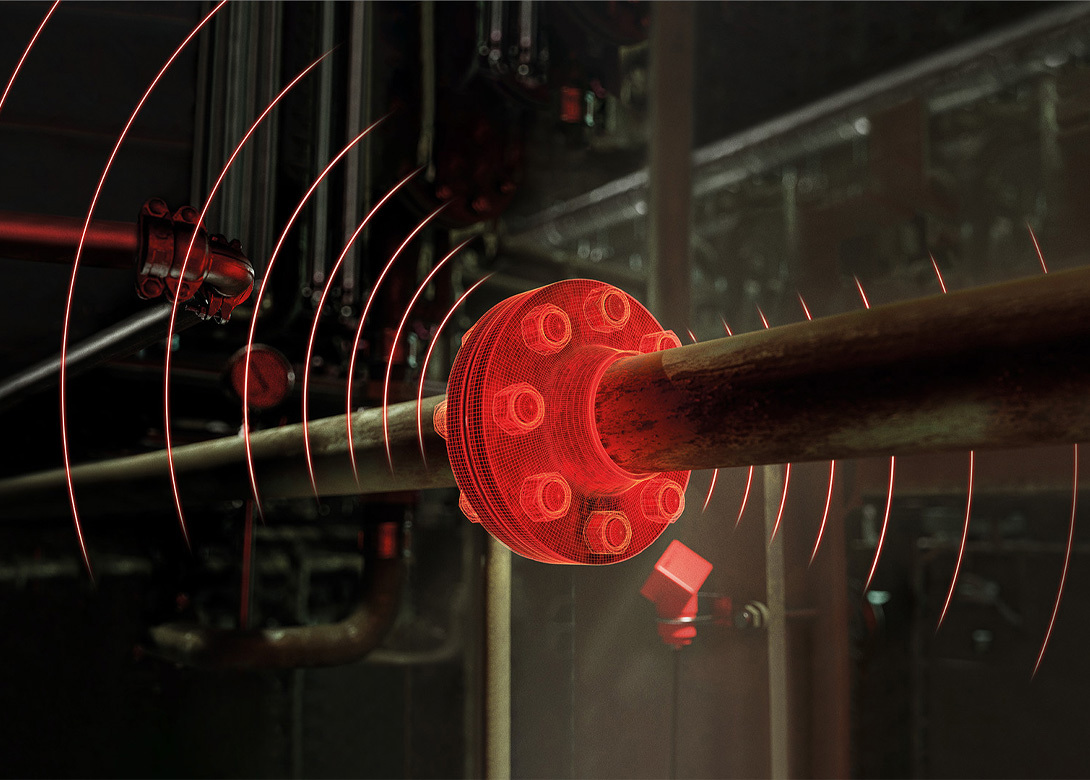

The first Pulse solution, LOCTITE Pulse Smart Flange Leak Detection, can detect early leakages and may be able to predict serious incidents. Critical assets can be monitored with a smart app and notifications are sent when irregularities are detected. This significantly decreases the risks of growing leaks to both operations and the environment, as well as contributing to sustainability.

Henkel states that customers in the oil and gas and chemical industries, such as Shell and H&R Group, have already installed the solution in their plants and are benefiting from intelligent monitoring.

H&R Group is a German manufacturer of mineral oil specialties. One of the challenges it faced was the numerous critical flanges which had to be monitored during production. Since most of these critical flanges are located under insulation or in hard-to-reach places, making visual inspection a difficult process. With LOCTITE Pulse Smart Flange, critical flanges can now be continuously monitored, enabling the detection of possible leaks at an early stage. This avoids costly repairs and unplanned downtime, while also providing an additional level of safety. “I now have an overview of the plant at all times and all locations,” comments Jan Hendrik Graef, head of operations at H&R.

Shell also utilised the LOCTITE Pulse system. The Shell Energy and Chemicals Park Rheinland is one of the largest chemical and energy sites in Germany. “In the past, the monitoring of our pipes and flanges was very complex and costly,” states Dr. Michael Hansen, engineering manager, Shell. “In particular around road junctions, we have a large number of assets which require an efficient and reliable monitoring solution,” adds Fabian van Straelen, senior asset inspector, Shell.

Using LOCTITE Pulse, these critical assets can now be continuously monitored and potential leaks can be detected at an early stage. “We are particularly impressed by three advantages of the Henkel solution: the simple and fast installation, the fact that leaks can be precisely localised and the possibility of rapid scaling,” highlights Dr. Michael Hansen.

“With LOCTITE Pulse Smart Flange, we have brought a solution to market that helps our customers address a problem for which they previously had no suitable solution. We help them to create an additional level of safety and, at the same time, support them in reducing expenses and increasing uptime. IoT, especially smart maintenance, is an important future growth area in which Henkel is consciously investing. Smart Flange represents the first of many solutions that will soon follow. Our goal is to offer our customers a broad portfolio of data driven solutions under the LOCTITE Pulse brand.” explains Dr. Michael Honné, head of MRO 4.0/Industry 4.0 at Henkel Adhesive Technologies.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.