For 16 years Ambrovit’s goal has always been the same - to provide a wide ranging clientele a total supply service, ensuring added value beyond the traditional business relationship with the supplier, with commitment and a serious approach.

Founded in 1997 by two managers with years of experience in nuts, bolts, and screws, Ambrovit, based in Garlasco, Pavia, Italy, is confident that it is currently a leading player in fastening systems. Why? Paired with the quality of its products, the service it offers is the decisive factor - prompt delivery and exceptional focus on the needs of the customer.

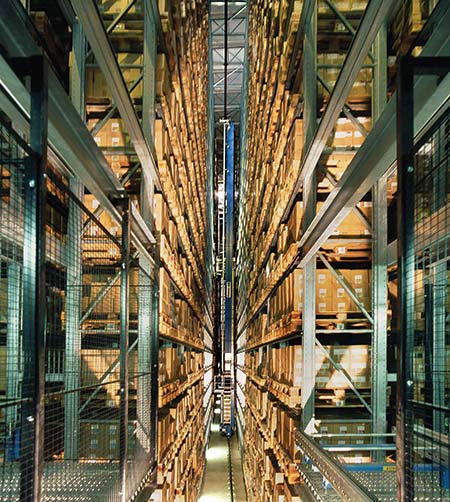

A technological facility

Today Ambrovit’s facility covers 12,000m², 6,000m² of which are occupied by warehouses. The company recently opened a completely automated warehouse - 28 metres high, for storage capacity of 22,000 pallet places and 1,400 pick rows. It is a technological space in which two automated Bilwinco packing lines operate with a daily capacity of 18,000 boxes – destined for customers in every sector from the furniture industry to manufacturers of doors and windows, as well as wood carpentry, joinery, metal structural work and garden furniture.

Storage systems

The new logistical offices, built in 2009, also made it possible to improve the control and storage of large quantities of material, making it easier to handle orders and for merchandise translation. Here, a modern building is home to the management, sales, and administrative offices. The advantages of the new centre? Greater simplicity and efficiency. In fact, the Garlasco facility also boasts a fully automated weighing and storage system that allows for optimum logistics management, ensuring the utmost efficiency in operations, both on a daily basis and in emergency situations.

Various products

Ambrovit produces a wide range of products, both in terms of the types of screws and bolts it offers and in terms of finishings and galvanising processes. Today, the catalogue offers accessories for fasteners, hex lag screws, screws for wood carpentry, chipboard and drywall screws, dome screws and Euro screws, machine screws, nuts, washers, bolts and threaded rods, tapping screws, drilling and S.S. A2 screws, as well as carbon steel fasteners (PVC-UP windows). These products range from 2mm to 30mm in diameter and from 4mm to 600mm in length. Each item is manufactured with specific steels depending on their type, and use, and undergo a range of processes including a carbonitriding heat process that helps the screws penetrate hard materials. Ambrovit can also offer galvanisation to confer colour and resistance to atmospheric agents, including trivalent white zinc coating in accordance with European Directive RoHS 2011/65/CE (Restriction of Hazardous Substances Directive) – yellow and black zinc coating is available from stock. Cosmetic bronze-plating, nickel-plating and brass-plating treatments are also available.

The special RUSPERT 1,000 hours treatment will soon be available for wooden carpentry screws. This three-layer non-organic ceramic coating delivers advanced resistance to corrosion. In addition to guaranteeing up to 1,000 hours of resistance in salt fog in accordance with ISO 9227, this finish also improves the performance of the screw.

Special zinc finishes are also available upon request, offering advanced resistance of up to 380 hours in salt fog.

Packaging and logistics

Product packaging plays a pivotal role at Ambrovit with items boxed internally to ensure quality in this area. All products in the catalogue are packaged in corrugated cardboard boxes printed with labels identifying the product, bundled or delivered loose in 20kg cardboard boxes, in polypropylene sacks or in recyclable plastic bags up to a maximum of 1kg.

Looking abroad

Ambrovit is increasingly open to foreign markets, thanks to its participation in international fairs, including Fastener Fair Stuttgart, Hannover, Russia, Batimat in Paris, and Eisenwarenmesse Köln. These are all opportunities that have allowed the company to take on a leading role worldwide, opening itself to new importing countries. These include: Germany, France, the UK, Spain, Portugal, Greece, Belgium, Russia, Slovenia, Croatia, Hungary, Romania, Bulgaria, Slovakia, the Czech Republic, Poland, Estonia, Lithuania, Latvia, Albania, Macedonia, Sweden, Denmark, Austria, Bosnia Herzegovina, Cyprus, Montenegro, Morocco, the Netherlands, Switzerland, and Tunisia. Growth in Europe has seen exports increase to 40% of current sales.

The future for Ambrovit

“Professionalism and a serious approach will continue to be the company’s prime features. Over the years the company will continue to grow the level of its service and strengthen its presence to respond to the new challenges posed by national and international markets. It will continue to hold its name high. Our motto remains – ‘We’re by your side in the world of fasteners’.”

It’s all certified

At Ambrovit the concept of quality touches every area of the company. The new lab features the latest generation of tools for quality control and the most sophisticated software, underlining Ambrovit’s commitment.

In 2011 Ambrovit earned Quality Management System Certification in accordance with ISO 9001:2008. Periodic oversight audits performed by TÜV on all manufacturing processes also guarantee compliance with all requirements of the international standard. Other certifications include European standard 14592, which dictates all the size parameters, tests to conduct, and quality control methods that the product must satisfy to be declared compliant and receive CE marking.

During the quality control process for incoming products, Ambrovit also conducts various checks and tests in its internal laboratory, and in addition works in collaboration with mechanical and structural engineering department laboratories at the University of Trento. On the Russian market, Ambrovit has also earned the Gost R certificate of conformity, demonstrating its compliance with essential safety requirements. Also for the Russian market, Ambrovit has earned certification from the Russian Association of Wood Housing.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.