CNC, a company based in Denmark, has developed an onsite method for repairing the blade roots in wind turbines. Using a portable machining tool, faulty inserts can be drilled away from the composite materials of the blade.

Previously, blade root damage to older wind turbines could only be repaired at the manufacturing site, requiring expensive logistics and long downtime. Over time, the threaded inserts used for joining the blade to the nacelle hub can become loose. In older blades, microcracks can form, allowing contaminants, such as grease and hydraulic oil, to weaken the bonding. With its new portable tool, developed to efficiently replace damaged inserts in blade roots, CNC Onsite can provide precision repairs carried out at the wind farm.

“For every handling and transport process, you risk damaging the blade structure, so in all aspects a repair job onsite is preferable when you can achieve the quality we are able to, with our new service,” explains Søren Kellenberger, sales director and partner, CNC Onsite.

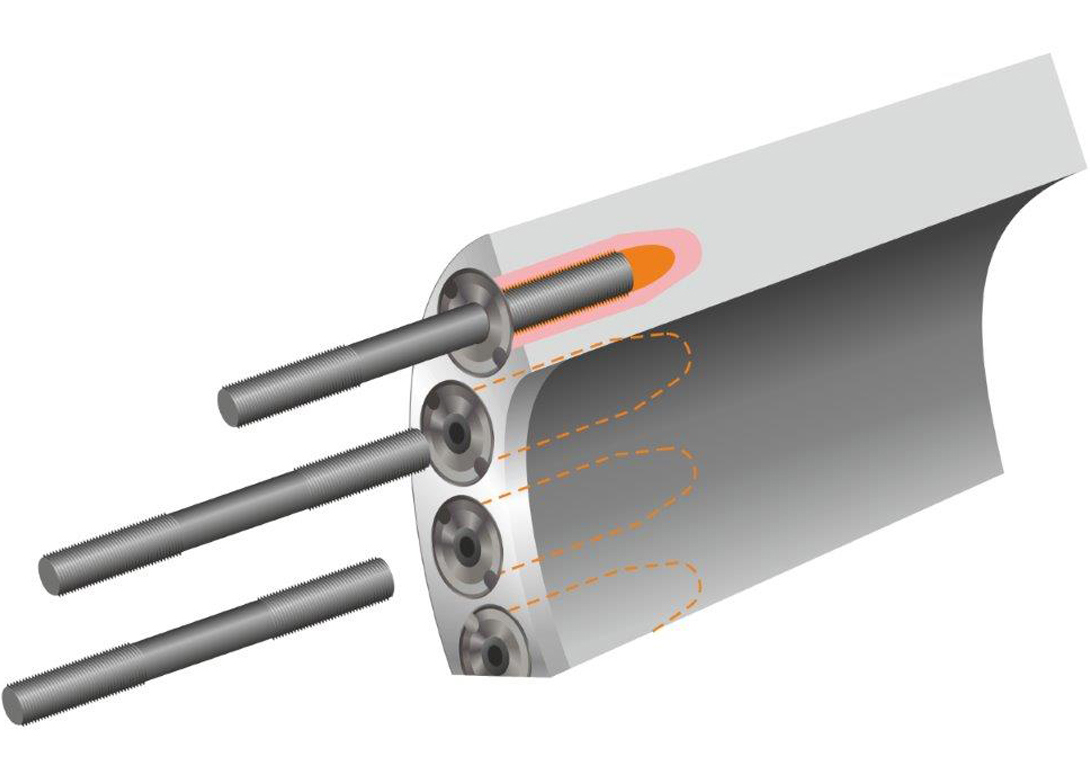

With CNC’s method, the rotor blade is dismounted, then placed in a repair environment at the wind farm. The portable, automatic machining tool is aligned to the blade and drills away the faulty inserts from the composite material. To ensure the cavity matches the exact diameter and shape of the replacement part, an additional, precise drilling process is performed so the new part can be inserted and fastened using bonding material.

“Repairing the blade root inserts onsite can be a complex operation. You need to be able to control several process parameters to ensure you do not do more damage to the blade and it is important to drill exactly in the center of the existing inserts,” adds Kellenberger.

CNC Onsite and We4Ce

CNC Onsite collaborated with We4Ce, an international blade rotor and blade root connection company, to deliver this repair solution focused on high strength blade roots. “The difficult parts of replacing a threaded are, firstly, centering the replacement part and secondly, the processing technology for the bond. Based on our track record since 2008, we have developed inserts with a design that considers both. This full solution offers consistent and stronger bond between the insert and the blade,” explains Edo Kuipers, engineering manager and co-owner of We4Ce.

CNC’s solution premiere

Issues with threaded inserts are usually detected during maintenance and mostly occur in turbines older than 10 years. The new CNC blade root repair is estimated to take two to three days, depending on the number of faulty inserts. “From our many discussions with potential customers, it is clear there is a need for onsite repair. From late autumn this year we will be offering the service, which we believe is the first on-site method. This will be available for all blade sizes,” concludes Kellenberger.

CNC’s blade repair solution will premiere at the WindEnergy Hamburg exhibition at the end of September.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.