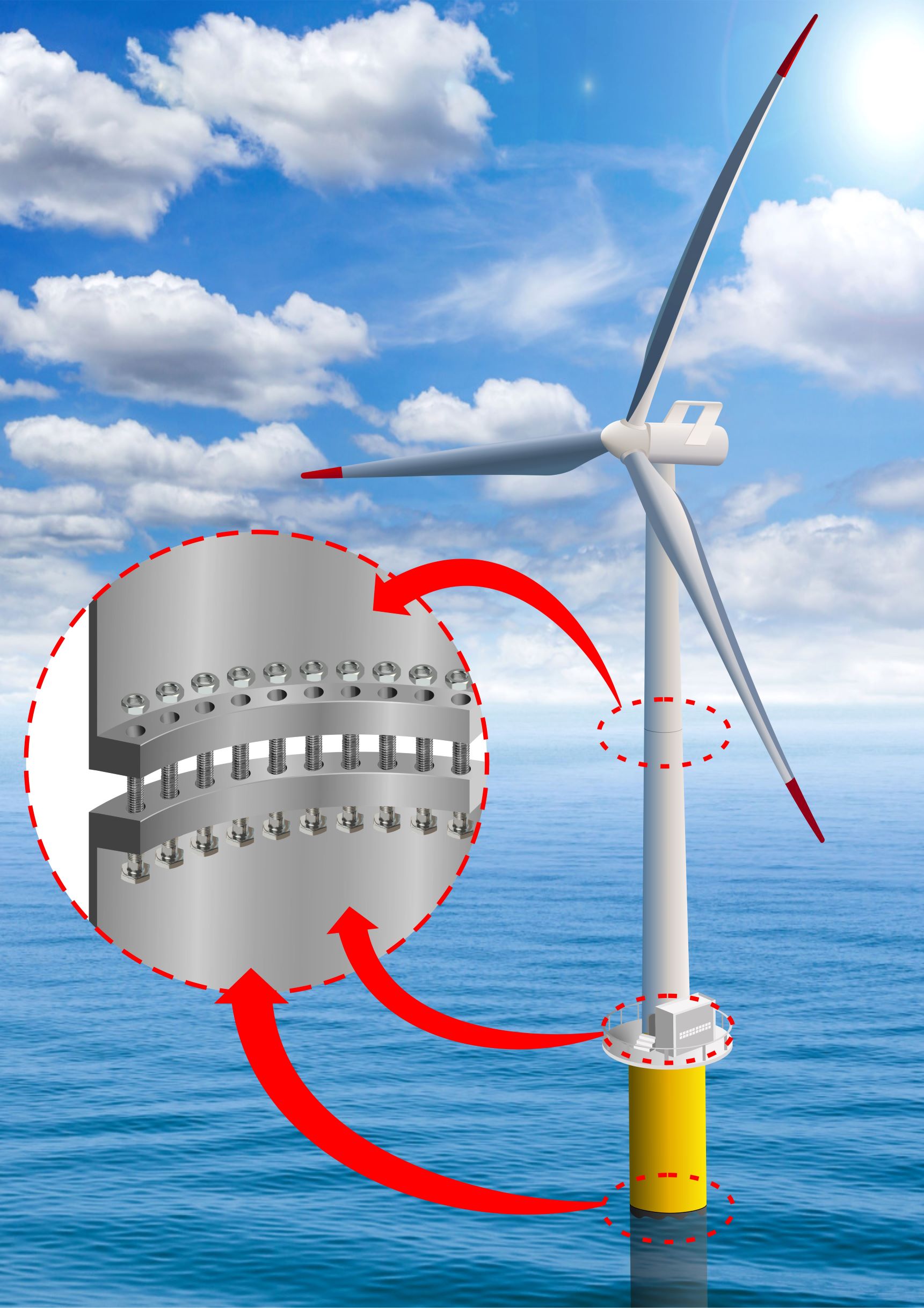

CNC has released a new flange facing tool ‘Goliath’ for precise flange connections in tower bases, monopiles and transition pieces. A product, the company claims, will improve maintenance costs, reliability and service life.

The increasing dimensions of wind turbines derived from operating in harsher offshore environments create engineering challenges for large flange connections that join wind turbine towers to their foundations. To prevent bolts loosening, an issue often associated with significant repair costs and downtime, the connecting flanges must be flat within millimeters.

A critical mechanical joint within the wind turbine structure, large flanges are technically complex to mount reliably, requiring pairs of matching surfaces fixed in place with bolts. After the manufacturer has welded the flange into the structure, a process that often warps the flange, the surfaces have traditionally been corrected by hand using heat treatment to produce similar skewness. Goliath, CNC insists, achieves fine tolerances as part of the production process post welding by milling, grinding and grooving the flanges to create faces with the required structural fit.

CNC has applied its experience in developing and operating flange milling machines to Goliath, making it stiffer, stronger and more precise than the previous machines.

“Obtaining a global flatness of a couple of millimeters on a 4m - 5m diameter flange can be challenging enough. But obtaining the same result on today’s eight plus meter flanges is simply not possible with previous methods,” explains Søren Kellenberger, sales director, CNC Onsite. “Once it is up and running in the autumn, we would not be surprised if we can obtain even better tolerances.”

Bladt Industry to incorporate precision flange milling

With offshore requirements driving ever growing turbines, the wind energy industry continues to innovate, integrating suppliers’ technology into their manufacturing processes. As a longstanding supplier of foundations and transition pieces, Bladt Industries conforms to this trend.

“We constantly develop our manufacturing to ensure we can deliver the right products with the right tolerances that the industry requests. With larger flanges, integrating Goliath into our manufacturing process will allow us to continue to do just that,” says Klaus Munck Ramussen, senior vice-president, Bladt Industries. “We are proud to support the development of the industry and, by securing the tolerances, we contribute to securing the integrity of these large structures and thereby the production of green power for many years,” he adds.

Flatness and fatigue can affect bolts

Achieving the best possible fit between the wind turbine tower flange and its base during the manufacturing process reduces the requirement for routine retightening and associated downtime. It can also potentially lead to longer wind turbine service life. An offshore wind turbine standing idle can cost more than €8,000 a day, with transport and labour costs coming on top. Maintenance over the lifetime of a wind turbine can represent up to a quarter of all costs.

“Because incorrect bolt tension is so problematic, the industry has long aspired to maintenance free bolted connections that require two criteria - sufficiently flat flanges and correctly tightened bolts,” explains Kellenberger. “Today, reliable bolt tightening methods are available to manufacturers. If the flanges are skewed, however, the bolts can still fatigue, even break, potentially leading to a complete collapse of the turbine.”

CNC state their Goliath product is a solution that delivers precise flange flatness is now on the market, which together with precise bolt tensioning, will help to secure the integrity of the structures and therefore reduce maintenance costs.

Flange milling solutions for all turbine towers

In addition to Goliath, CNC offers a range of in-house flange facing tools that cover diameters from 1.8m - 10m. “Working automatically using pre-programmed parameters. Goliath, which can work both horizontally and vertically, can cope with features on large flanges such as double tilted flanges and requirements for parallelism of the flange surfaces,” says Kellenberger. “The Goliath machine can manage the many new complex flange designs, making it probably the most advanced and precise flange milling tool on the market.” Designed to work quickly without compromising the high precision work, the tool carries out some steps simultaneously to save time.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.