Wear and galling of stainless steel components within the hydrogen sector is a common problem, a problem which is solved by processes known to negatively affect corrosion resistance. Now, Expanite is providing a gas-based diffusion process as an alternative solution.

Hydrogen has gradually become the energy source of the future, already used in many sectors, whether applied in shipping, steel production or refineries. As the smallest and lightest atom among all elements, it has been traded for some time with hope for future energy supply. Due to its special properties, hydrogen gas poses several technical challenges for the respective components with which it comes into contact. So, the use of corrosion resistant stainless steel is essential.

Throughout production and usage, wherever hydrogen is involved, stainless steel components are also used. Components which are susceptible to extreme wear depending on the application and naturally subject to galling. In the past, this problem was countered with traditional wear protection methods and the respective components were protected with a coating, such as chrome carbide, or classic plasma nitriding, or salt bath diffusion layers. However, these processes are generally known to affect the corrosion resistance of the stainless steel parts negatively.

The solution to this dilemma, a surface hardening that protects against wear and galling while, at the same time, maintains or improves the corrosion resistance of the materials. Such a solution is provided by Expanite and is increasingly being used in the hydrogen sector.

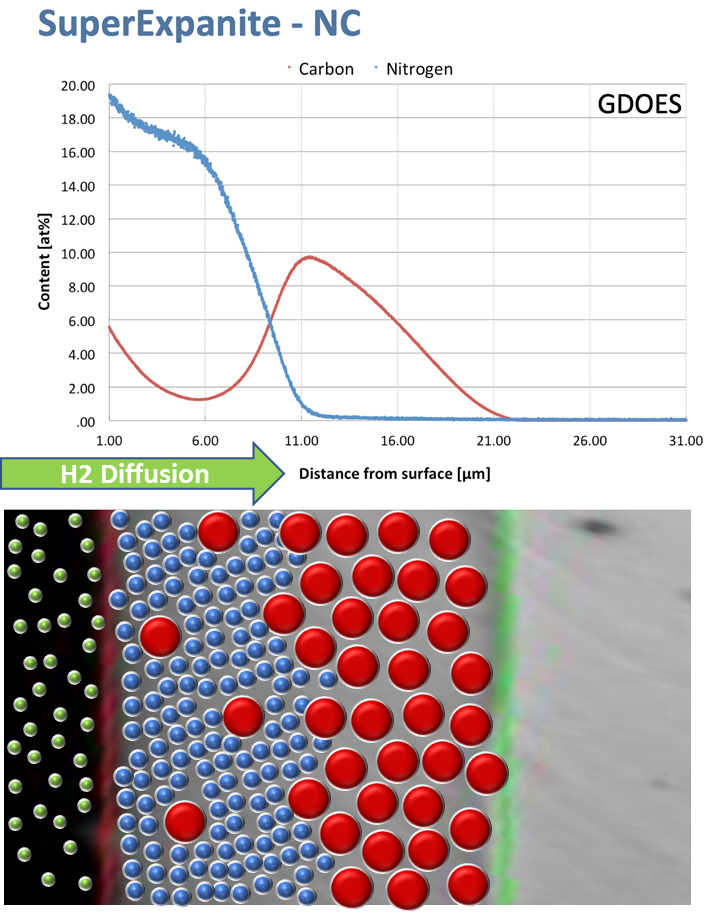

"Our customers often ask whether the Expanite technology increases the risk of hydrogen embrittlement, which is not the case," explains Dr. Holger Selg, application expert and Expanite sales director DACH. "The cause of the hydrogen embrittlement can be traced back to the diffusion of the hydrogen into the material and, in theory, the Expanite layer acts as a diffusion brake to a certain extent. Charged with nitrogen and carbon, the Expanite surface is harder for the hydrogen to penetrate than an untreated surface.”

The gas-based diffusion process from Expanite, the company insists, is more energy efficient and environmentally friendly than comparable wear protection processes and, thanks to the treatment in a vacuum, has no need for time-consuming cleaning of the parts.

The Expanite technology, specially developed for corrosion resistant materials, offers a solution for austenitic, martensitic, ferritic and duplex stainless steels, as well as for expensive nickel-based alloys such as Inconel and Hastelloy. The new process, ExpaniteHard-Ti, is used for titanium materials.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.