Since being acquired by Optimas Solutions in November 2015, Barton Coldform has experienced a significant period of investment, resulting in a big infrastructure upgrade. Editor Will Lowry visited the company’s operation in Droitwich, Worcestershire, and spoke to Operations Director Aaron Milborrow about what it means for customers.

Barton Coldform is now the European manufacturing division of Optimas and provides a support function to the Group’s suppliers. To enable it to continue to supply, and even expand the product offering, Barton’s manufacturing facilities have expanded massively over the last three years – going from 19 to 32 heading machines, and from 9 to 15 thread rollers. It has also taken on 12 extra staff members and introduced an additional structure at the back of the facility to hold more raw material.

“Adding the extra manufacturing capacity was a combination of developing our product range, as well as taking advantage of investment opportunities to buy new machinery and bring on additional employees,” explains Aaron. “This has resulted in us significantly expanding our capabilities.”

After acquiring the additional machinery, it needed to be placed on the shop floor without impacting on production. “Everything on the shop floor, except one machine, has moved,” mentions Aaron. “We had three months to get all the equipment in place; set the infrastructure and power; build a set of offices; and move the washer plant and tool room. It was a big team effort.”

A vital part of the restructure was to ensure all of the headers were reachable by the crane, which is located in one half of the facility. “The crane enables us to deliver material easily to the machines and keeps fork lift trucks off the production floor,” says Aaron. “It also helps if we need to do any machine repairs or preventative maintenance.”

The new floor layout has also helped optimise the production process, with a ‘u’ shape flow of material around the factory. “Previously it was more of a lateral flow, so the new design has improved our efficiency. Even though we have become far more compact with the space in between the banks of machines.”

In addition to the machinery, Optimas was able to add employees that already had experience of fastener production, which was a huge benefit. “We recognise there is a shortage of skills in the forging industry, so being able to bring in experienced employees was a big positive – we didn’t want to lose the knowledge and skill base,” states Aaron. “We have tried to match the people with the machines they have experience using. Whilst some of the skills are transferable, there are specifics to each machine that setters know better than anybody else. This is why we are introducing a cross skilling programme this year, where employees will work on different sets of equipment to further expand their skill set and experience within the business.”

To further combat the skills gap, an apprenticeship scheme has also been introduced. Three apprentices were employed last year, and the company has taken on another three apprentices this year. “Last year we interviewed 15 apprentices for the three vacancies and there was a genuine interest in wanting to work on the shop floor – which five years ago wasn’t true,” explains Aaron. “The apprenticeship scheme is an important step, but it takes five years for an apprentice to gain the experience and skills to be fully up to speed with the machines, so there is still a long way to go before we will be happy with the balance.”

The final infrastructure addition was a new warehouse at the back of the facility for wire storage, with space for 4 – 6 weeks of material. A further one week of stock is stored inside the main building – located under the crane. “The new facility makes it easier for us to store the coiled wire and ensures an effective and efficient flow to the machines,” says Aaron. “We are also in the early stages of trialling a Kanban system to ensure machine specific wire is delivered as and when required.”

Management have also reintroduced the 5S workplace organisation method to the shop floor, which previously proved very successful. “For the 18 months we were expanding the 5S lapsed a little bit, but we still recognised the benefits. We therefore reemphasised the importance of 5S at the end of last year and we immediately saw significant improvement. We are continuing it this year by using layered auditing, with management and director teams, to ensure it stays a vital part of the production structure.”

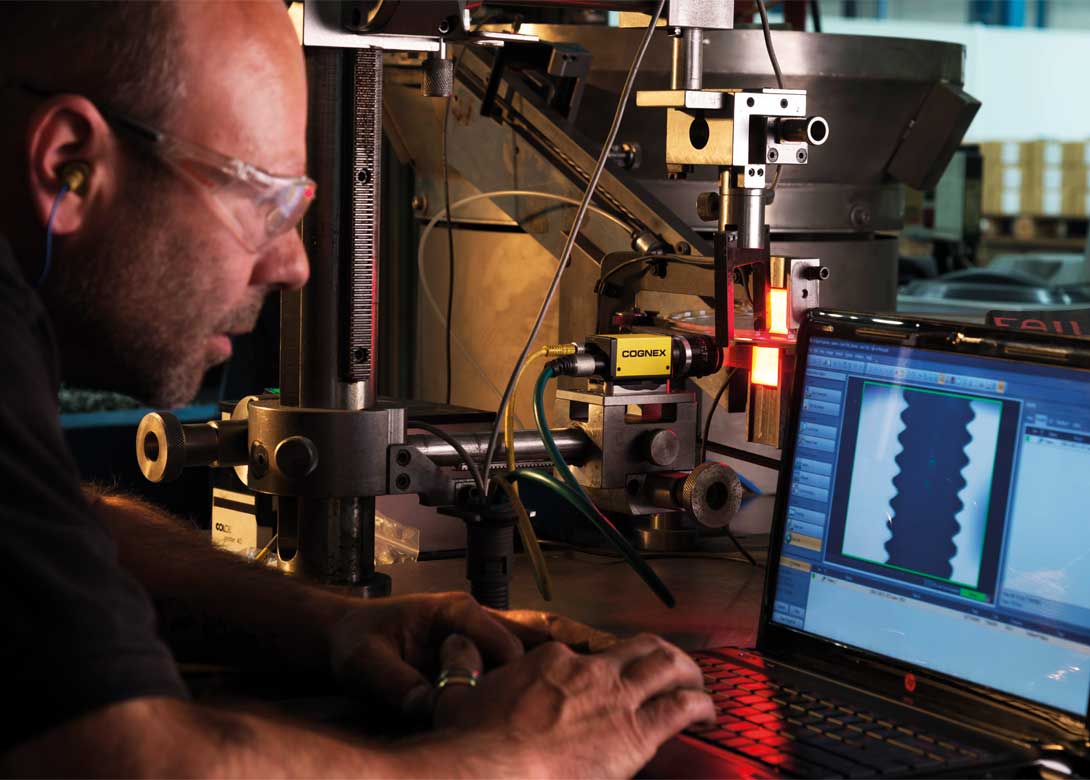

Another recent addition to the Barton site has been a laboratory, which used to be situated in Optimas’ distribution centre in Gloucester. “When we were acquired by Optimas it was decided the laboratory should be available to manufacturing and located within the manufacturing operations,” explains Aaron. “The range of services provided by the laboratory includes, but is not limited to, mechanical testing, metallurgical testing, chemical analysis, failure investigation and product finish testing.”

Providing additional services is a key theme for Barton and being part of the Optimas Group has enabled it to further develop its offering. “Optimas has engineers working alongside our major customers to understand the challenges they are facing,” points out Aaron. “This means we are embedded with the customers and can discuss new ideas and offer help. From a manufacturing point of view, we are supporting the engineering team by providing prototypes that can be tested, as well as any other production requirements they may need.”

Aaron continues: “We are finding the earlier engagement is enabling the customer to reduce costs in its manufacturing process. It is not just the quality that is crucial, but the overall cost of acquisition and that includes the manufacturing processes customers are using. As a UK manufacturer we can provide lifetime quality as well as a shorter supply chain. Also, apart from raw material, every part of the manufacturing process is carried out within the UK – part production, tools, heat treatment and plating – aiding with lead times and reducing the movement of parts.”

The Barton facility is also able to work with customers on developing new products and has acquired the licence to produce Taptite® and Mortorq® products. “With Taptite customers don’t have to have a threaded hole, the Taptite creates its own thread – taking a process away for the customers, which is a big advantage,” mentions Aaron. “With Mortorq there is a weight benefit and it has a better driveability and removal than other competitors – due to the features of the head enabling more engagement – again providing an advantage to customers. We can offer customers these different options and ensure an optimal solution.”

A new service that Optimas is currently promoting through its manufacturing capabilities is its Express Service, which provides customers with the opportunity to receive small volume parts quickly to meet demands – helping to further shorten lead times and help reduce supply pressure on manufacturers to meet project and development deadlines. “The Express Service is a totally different area that we haven’t previously been involved with,” mentions Aaron. “The cost of developing tooling, and the time to set up cold forming machines, often results in the process being only used for high quantities – making it ineffective for prototypes or to provide samples. By bar turning the parts we can reduce lead times from weeks to days, which can be crucial for customers. The bar turning process requires no special tooling, only raw material, which is why we can be so responsive. It also means if a customer wants to change the design it is easier to do so. There can be a huge cost involved sometimes with cold forging.”

With new services and the infrastructure now fully up and running, the target for the next 2 – 3 years is to start filling the facility’s capacity with work. “At the moment Barton supplies 55% of production to Optimas with the remaining 45% going to third party companies, which are historical to Barton. Our intention is to continue working with our third party customers, whilst growing with Optimas.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.