By Thomas Henriksen, president and CEO, Ceramco Inc

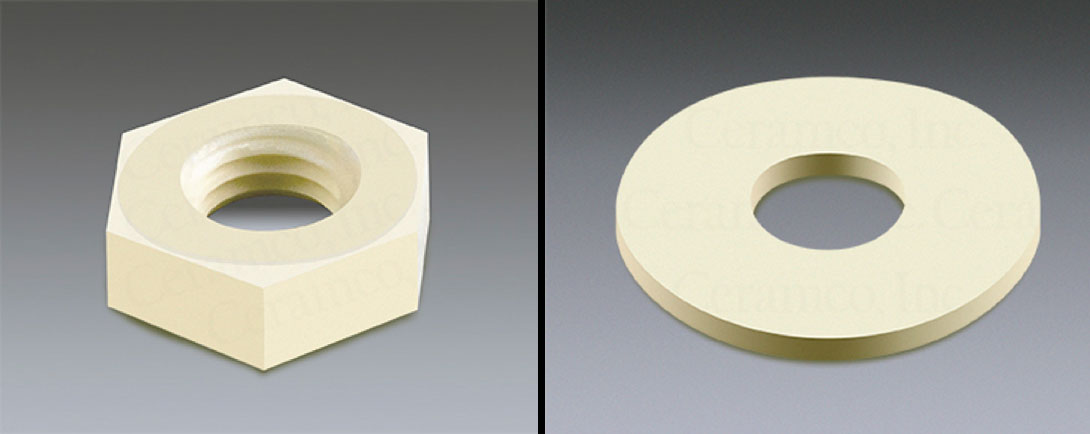

If speciality fasteners were defined as any fastener manufactured of non-traditional materials, ceramic fasteners would be listed as one the most specialised. In the 1980s, Ceramco manufactured nuts, bolts and washers out of a common technical ceramic material called aluminium oxide, which ordinarily you would not want a bolt to be made from, because of the brittle failure mode of this material. However, today ceramic fasteners are a critical product line for aerospace, medical, green energy, and other markets.

The general properties that ceramic fasteners have, which are attractive for aerospace environments include weight savings, durability (resistance to wear, corrosion, etc), rigidity, and operating temperature range. Furthermore, they are used widely in the scientific instrumentation that supports aerospace and space. Ceramic fibre reinforced composite fasteners for structural applications are highly specialised and reserved for extreme environments. There are however several ceramic materials (not fibre reinforced) that have application inside and outside of the Earth’s atmosphere.

In one instance, for a commercial satellite launch, a tough, rigid fastener was needed, with a vent hole, to prevent pressure differential in the assembly. A ceramic material called YTZP zirconia (Yttria stabilised tetragonal zirconia polycrystal), which actually has similar CTE (coefficient of thermal expansion) as stainless steel, and exhibits a toughness like metal, was used to make a vented #4-40 hex head bolt. Static electricity build up and/or discharge was also a concern in this application, and ceramics in general are not electrical conductors, they are isolators or insulators.

YTZP zirconia is tough and competitive with stainless steel in properties, it is however quite heavy, with density of about 6g/cc. Silicon Nitride (Si3N4) is also an extremely tough ceramic, but at almost half the weight, with density of about 3.25g/cc. This fascinating material has application for harsh environments particularly for wear resistance and toughness, while offering significant weight reduction. Typical grades can perform up to about 1,200°C but it can also be alloyed to increase the service temperature range.

On the opposite side of the strength spectrum, but untouched in terms of weight and thermal shock resistance, is a ceramic known as fused silica. Speciality fasteners for leading edge shielding/cladding have been made in this material for decades. It is super lightweight with density of just 1.7g/cc and it virtually has no CTE, so any rapid increase in temperature, such as the heat generated upon re-entry into the Earth’s atmosphere, does not affect the fastener. Thermal shock is a concern with most high strength, full density ceramics, because of phase changes in the microstructure at certain temperatures, but it’s not the case with fused silica.

Although the perceived weakness of ceramic fasteners is their brittle failure mode, in certain applications, their usage can be designed in, for perhaps the less structural functions that fasteners can also have. Ceramics love compression, but they do not handle tensile forces so well, though they are still quite strong. It is the lack of ductility that prevents them from being over tightened. Fasteners made of polymers mostly have the opposite issue; they are so ductile you can stretch and bend them, but they are lacking in strength significantly. Plastic fasteners certainly do have application in aerospace, as they are lightweight, and don’t conduct electricity either. In cases where corrosion and elevated temperature are a concern, ceramic would be a more suitable material selection (when metal cannot be used).

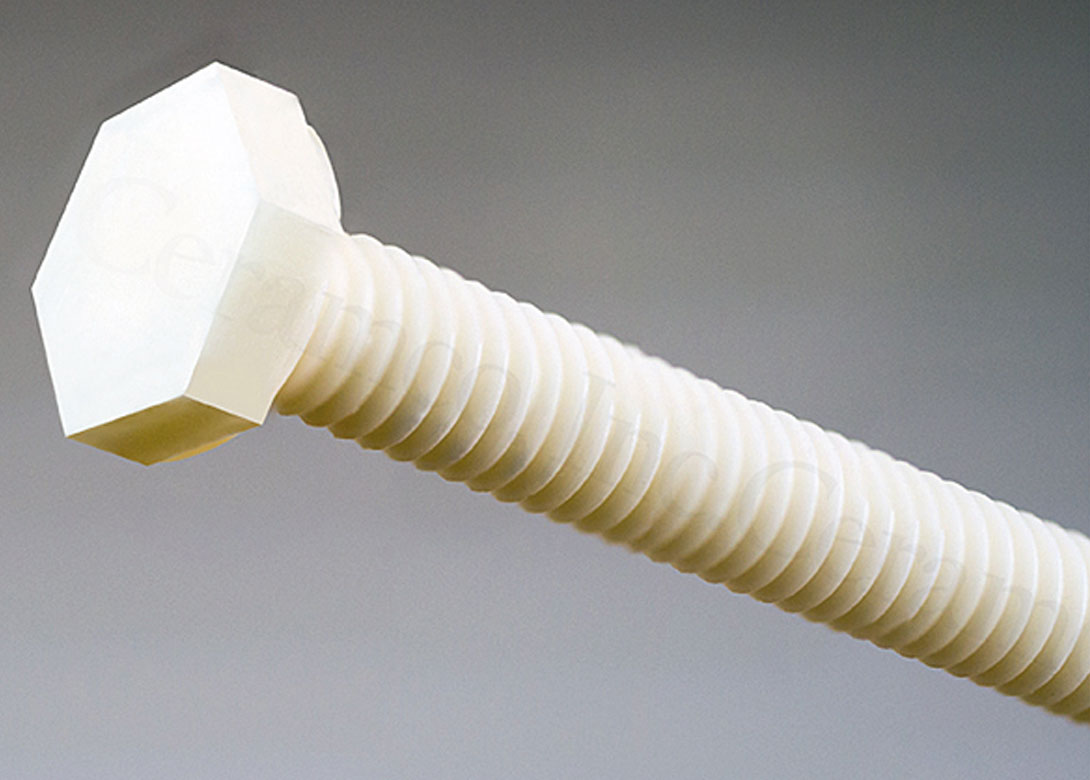

Cost is also a factor when considering ceramic fasteners, since they are still a low volume, speciality fastener. It is mostly the processing that adds to the overall cost, as opposed to actual raw material cost. To that end, there certainly are some novel metal alloys and high performance plastics that cost even more than most ceramic materials, but the manufacturing burden is lower. Not that machining high nickel or titanium alloys is fun and easy, or moulding and machining the seemingly lawless plastics, but all ceramics must go through high temperature treatment (firing or sintering) and that process alone is costly and time consuming. Machining ceramics is also very expensive, because if it is done in the fully fired state, they are so hard at that point that you must use diamond tooling. Alumina, zirconia and silicon nitride are off the charts for Rockwell hardness. Carbide cannot even scratch them. So net shaping of ceramics is ideal, not just for economy but also for performance.

This is because failure modes of ceramics are essentially from point defects, where a defect can act as a stress concentrator and give a place for a failure crack to initiate in the ceramic. If you grind a ceramic too aggressively, you may introduce microcracks, which will weaken the material. At Ceramco, we near-net shape all our threads for near conformance to ANSI specifications and without the added cost or harsh impact of grinding.

A new product for 2019 will be fasteners made in ZTA (zirconia toughened alumina), which (technically) is a composite material, although it is not the fibre reinforced kind, as it is taking ideal properties from two different ceramic materials combined in one. Zirconia offers toughness, which helps with mechanical performance, however it is heavy and expensive. Alumina has good electrical properties, is corrosion and wear resistant, and it is much lower cost as a raw material – but it is on the brittle side. ZTA hybridises these two materials for a tougher alumina fastener.

Then, in the further future perhaps, we will stock fasteners made in silicon nitride.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.