A new lubrication from Dörken MKS provides a high-level of corrosion protection and simultaneously enables a smooth fastening.

In order to prevent thread rolling screws from corroding, it is now possible to use a coating system from Dörken MKS-Systeme GmbH & Co KG consisting of a zinc flake basecoat and the DELTA-LUBE® 50 lubricant.

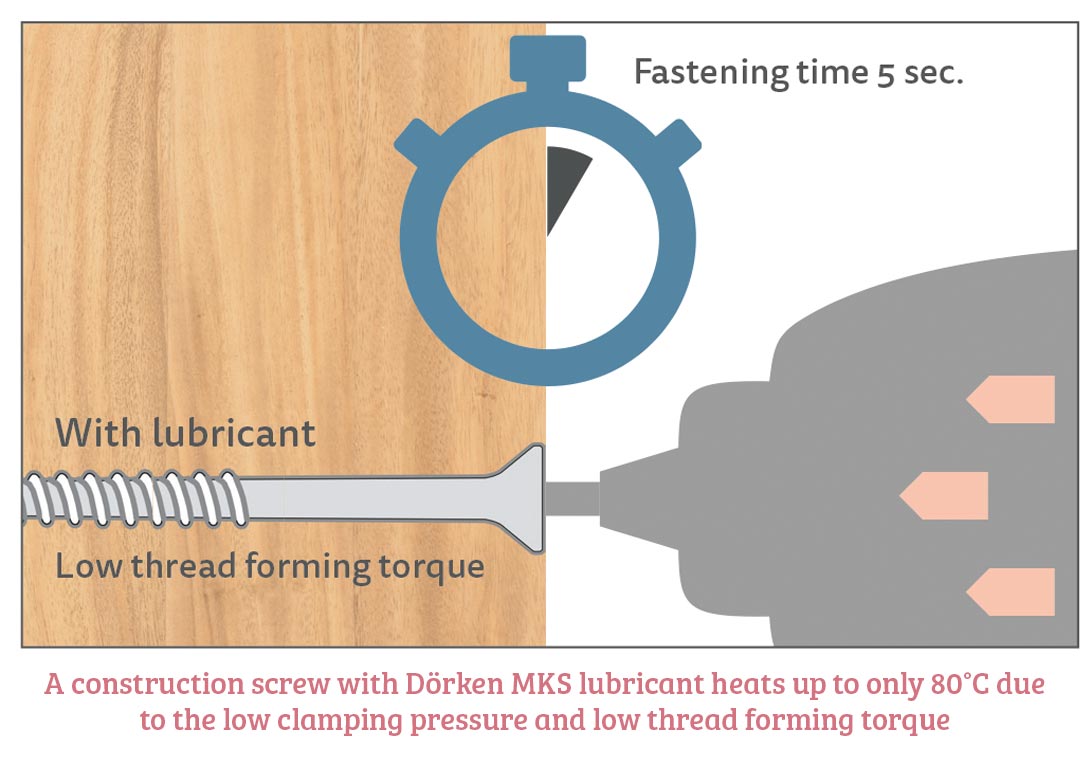

The basecoat determines the corrosion characteristics and ensures cathodic corrosion protection, while the colourless lubricant brings with it the properties of the otherwise used topcoat. Further increasing the corrosion protection and influencing both the coefficients of friction and thread forming torque.

Test results show that the coating system fulfils high corrosion protection requirements. It achieved 3,000 hours in aluminium without any red rust, and more than 1,000 hours in steel (salt spray test according to ISO 9227).

At the same time the system also achieves low levels of thread forming torque, thus enabling thread rolling screws to be reliably used. If the screw needs to be coated in colour, it is necessary to apply a topcoat before the lubricant. The surface protection from Dörken MKS is globally available and fulfils high-quality standards.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.