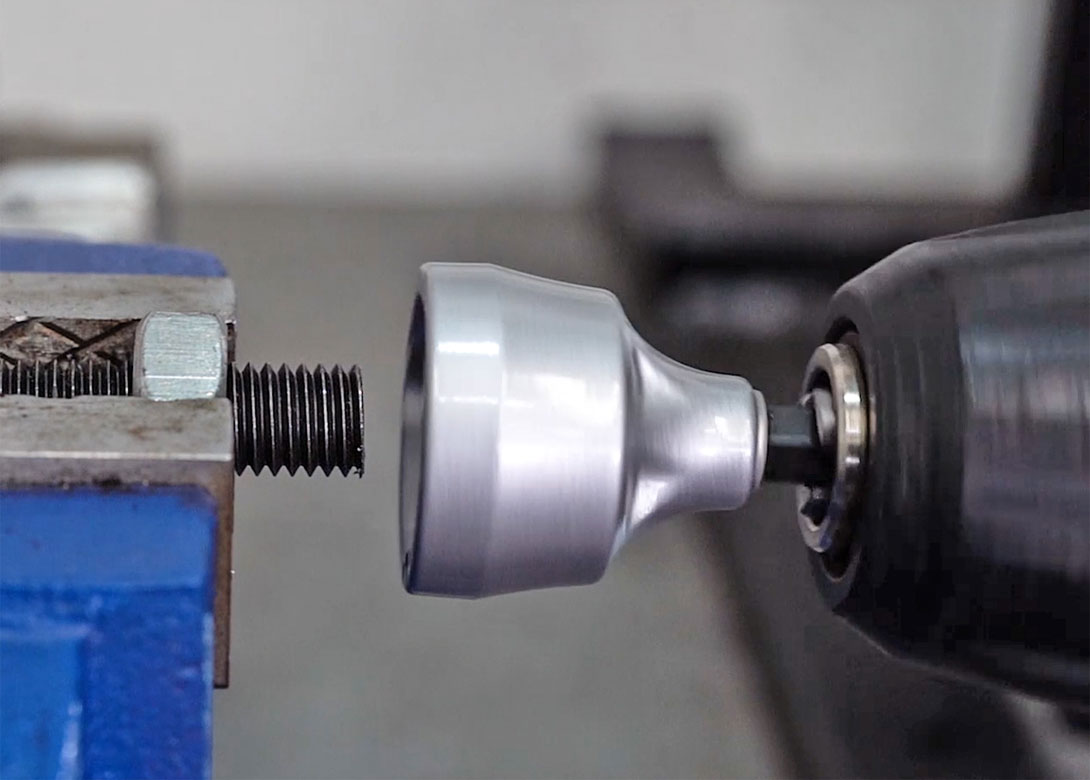

In a busy workshop there are numerous instances of threads getting damaged - whacking a track rod end with a hammer; cutting a bolt or threaded rod; whacking a driveshaft out of a hub - the threaded ends get torn and squashed. Wheel studs also get damaged just by removing and refitting the wheels. Luckily there is a quick and easy solution from Laser Tools: the external deburr and chamfer tool (part number 7510).

The chamfer tool is designed to be used with an electric drill and is fitted with a 1/4" quick-chuck shaft, maximum recommended speed is 400rpm. The tool is fitted with three super-hard high-speed steel blades that make light work of repairing damaged bolts and damaged threads. The blades cut quickly and cleanly and are effective on stainless steel, hardened steel, mild steel, copper, brass, wood, fibreglass, and even hard plastic. Bolts, studs and threaded rod, size range from 3mm right up to 19mm.

Hammer damage or squashed and flattened threads will stop the retaining nut or wheel nut screwing back on; a couple of zaps from the deburr/chamfer tool solves the problem instantly. Cutting steel or copper pipe can leave an uneven edge that can stop an olive or tube nut being slid on. A gentle touch with the tool leaves a nicely chamfered edge, and the olive slides straight on.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.