DELO has introduced a new, silicone-free liquid sealant for the automotive, electronics, and white goods industries. Curing by light, DELO PHOTOBOND SL4165 protects from dust, air, and water.

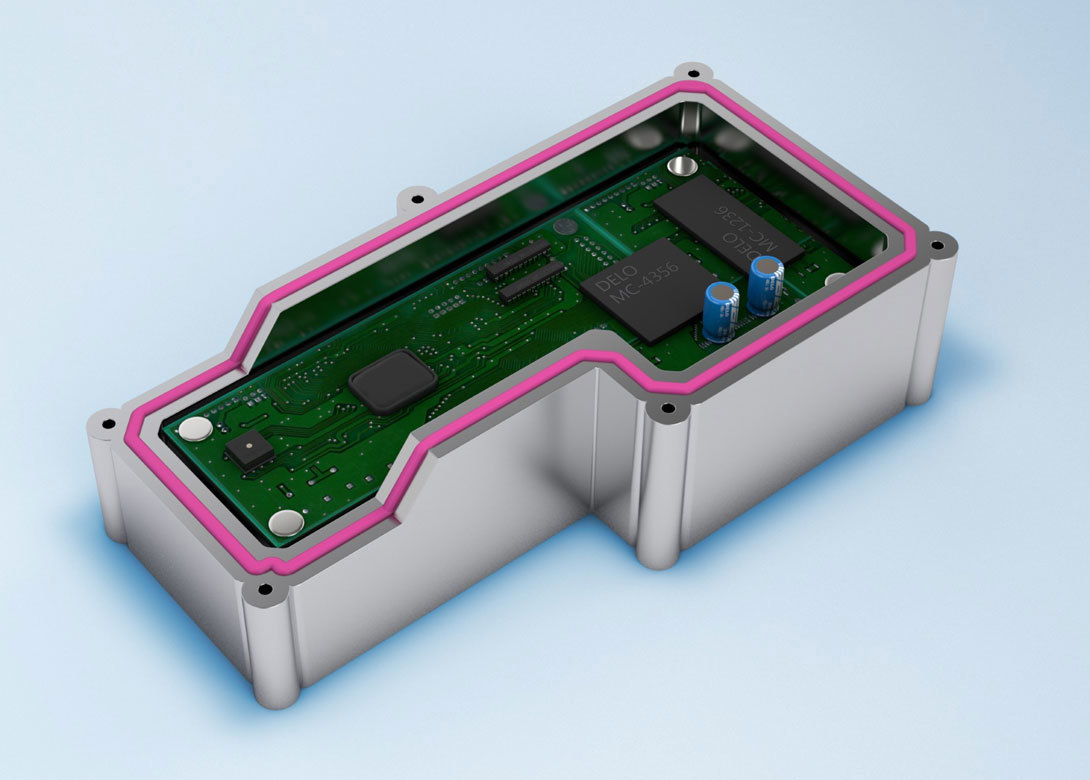

The flow resistant, highly viscous liquid sealant can be applied in the desired height and any geometric shape. The product cures by UV light or visible light in a matter of seconds without thermal influence, and thus enables the so-called CIPG process. CIPG stands for “cured-in-place gasket”, which means that the liquid sealant cures in the desired position so fast that the entire assembly can be directly further processed.

DELO PHOTOBOND SL4165 has a compression set of 15% and thus shows good elastic recovery – so the highly flexible material springs back after being compressed. These properties ensure reliable sealing and help manufacturers meet the tightness requirements according to IP67, the IP rating used for smartphone classification.

Thanks to their versatile application options, liquid sealants are particularly well suited for complex geometries. Compared to O-rings or moulded gaskets, they involve significantly fewer process steps and reduce machine setup times. Other benefits are fewer rejects and reduced storage costs. In addition, the production process can be easily automated, allowing any shape to be produced on one system. And finally, the product is suitable for in-line quality control through fluorescent detection of potential leaks.

DELO PHOTOBOND SL4165 is one component and free of solvents as well as paint wetting impairment substances. Its range of applications includes sealing of housings in the consumer industry such as white goods or landline and mobile phones. Using the CIPG material in the field of power electronics in cars such as in high-voltage accumulators or electronic transmission control components, can also be envisaged.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.