By Dr-Ing Hans-Albert Staedler, customer engineering director Europe, at Arconic Fastening Systems Industrial Products, Telford, UK

Arconic Fastening Systems has many years’ experience in mechanical fastening technologies. Louis Huck (the founder of Huck fasteners) developed in the middle of the forties the very first lock bolt system – which functionality is based on cold forming/extrusion technology.

A so-called collar gets cold formed during installation by an anvil (part of a special installation tool) into unique locking grooves of a pin. After the installation the fastener is mechanical locked due to this volume controlled swaging process. The locking grooves are more times filled with collar material. The system of this builds a natural barrier against vibration and clamp loss. Lock bolt systems create vibration resistant and high fatigue life joints.

Since the very first lock bolt these systems have been permanent optimised. A revolution was, when Arconic Fastening Systems came to the market with pintail less lock bolts. These systems do not more have a pintail end with blank and rust effected surface. The installation gets faster, smoother and with reduced noise compared with traditional lock bolts and much faster than conventional bolts.

Germany’s highest construction authority DIBt tested the Bobtail® in accordance with the EN 1993 regulation and approved it as opportunity to generate total maintenance free joints. The Bobtail® also delivers the performance of ISO 12944 C5 M corrosion protection.

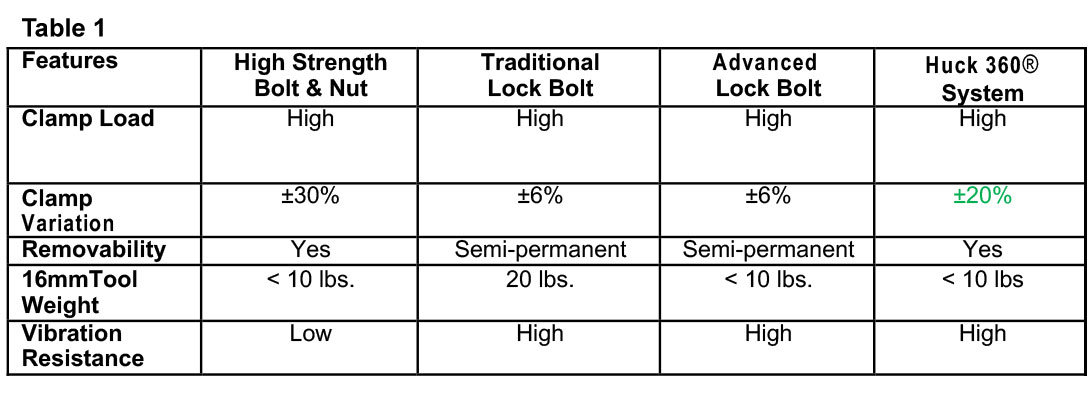

Table 1 below shows the evolution of lock bolt systems comparable with high strength conventional bolts (Source Arconic Fastening Systems and Rings test lab. Waco).

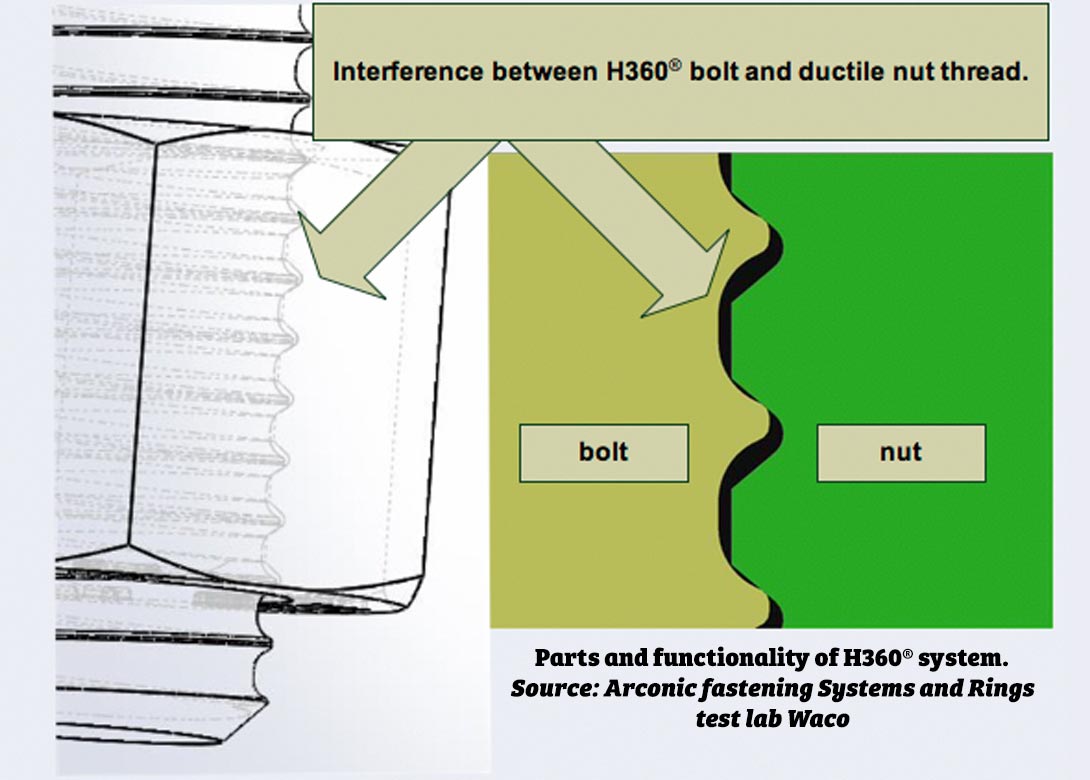

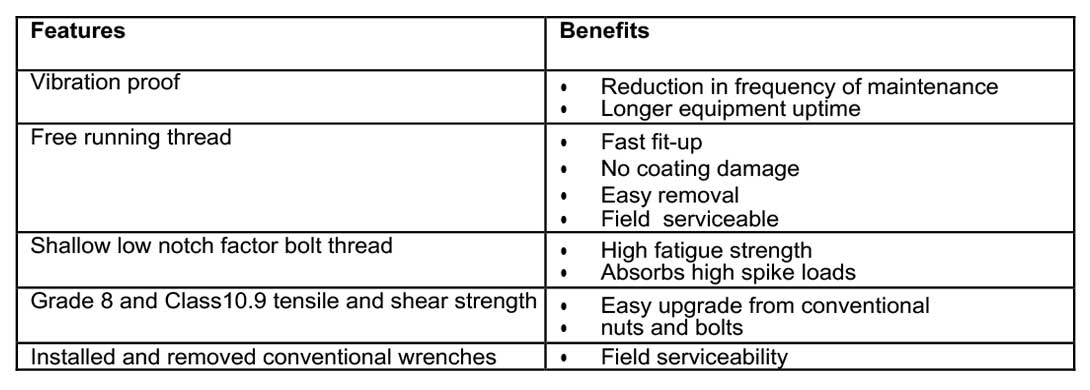

Not included in Table 1 is Arconic’s newest innovation - H360®. The Huck 360® is a removable and reusable nut and bolt system with lock bolt equivalent vibration resistance and high fatigue strength and has the installation flexibility of high strength bolt and nut systems. In comparison to lock bolt systems the H360 does not need a special installation tool, and due to the tightening installation method, the clamp variation is larger than Lock bolt systems, but smaller than conventional bolt systems. The ductile nut thread and its deformation during the tightening process generate a mechanical lock with the hardened thread of the pin.

Not included in Table 1 is Arconic’s newest innovation - H360®. The Huck 360® is a removable and reusable nut and bolt system with lock bolt equivalent vibration resistance and high fatigue strength and has the installation flexibility of high strength bolt and nut systems. In comparison to lock bolt systems the H360 does not need a special installation tool, and due to the tightening installation method, the clamp variation is larger than Lock bolt systems, but smaller than conventional bolt systems. The ductile nut thread and its deformation during the tightening process generate a mechanical lock with the hardened thread of the pin.

The free running nut thread quickly spins down and tightens while minimising damage to coatings. The H360® stays tight under severe vibration loading and superior fatigue strength holds up against high repetitive service loads. The preloaded H360® thread and conventional bolt/nut thread detail shows the difference and reason for this high resistance against vibration. The H360® bolt thread is similar to a lock bolt system, has mild contours and no stress concentration areas and deliver to the bolt a larger cross-sectional area than a conventional bolt thread. The nut thread is designed in a style, which deform during tightening process enough material for the locking mechanism. The nut thread is in ductile hardness and allows the removability and reusability. This means, that the system is suitable to solve work piece surface imperfections and/ or screw installation strategies for instance in large flange wind turbine towers.

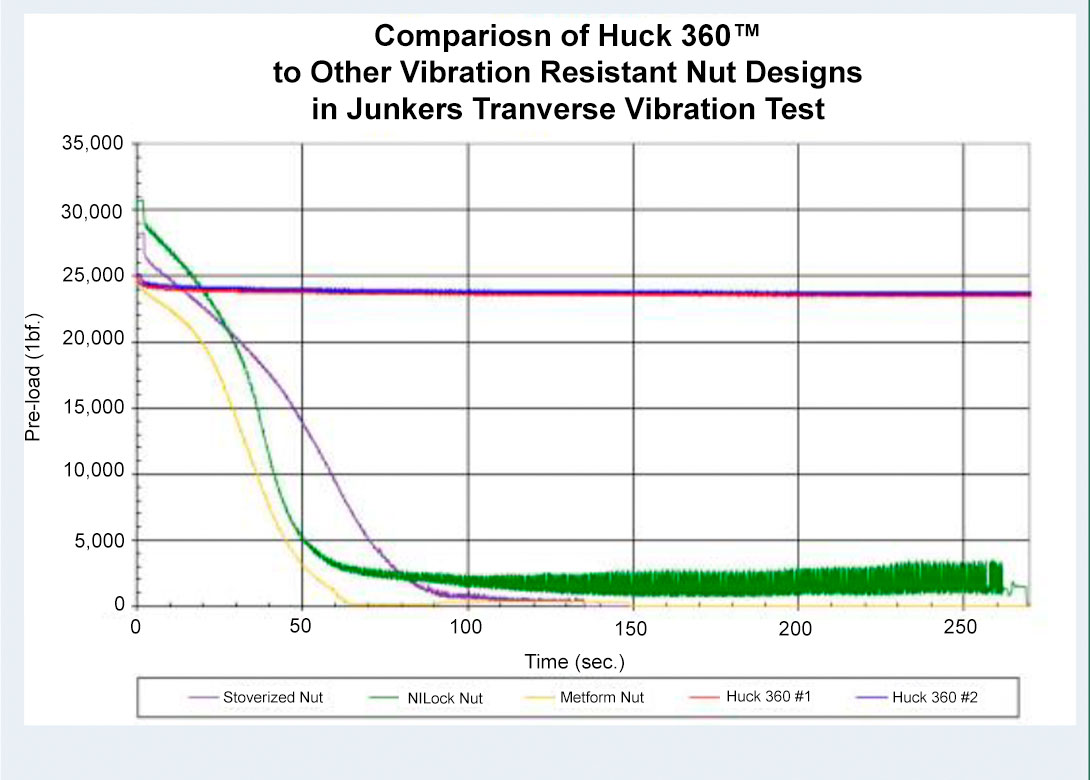

The Arconic internal comparison of H360® and other vibration resistant nut designs in Table 2 allows the following conclusions to be drawn:

The H360® system can be used in a number of industries such as steel construction, truck and trailer, agriculture, harvest machinery, rail and railcars, automotive and in the mining industry. Equipment manufacturer, Morbark Inc was having poor insert (tooth) life on a Model 1300 Tub Grinder, which used ¾ inch stoverised nuts and Grade 8 bolts. The company was losing “upwards of 6 - 8 teeth a day” per the operator. Using the Huck 360® it was able to accumulate approximately 120 hours over a period of five weeks. During that period of time only 8-10 inserts were lost.

In the steel construction market

Used in a number of applications, Huck 360® can be found in steel bridge construction, energy communication, radio telescopes, elevators, static bridges, mast and towers, solar construction to name a few.

For all applications in the construction market, though an approval is necessary. Arconic has therefore started the approach to a DIBt approval in Germany. This DIBt is the German authority for the fulfilment of technical tasks in the field of public law. This authority sets National Technical approvals. The DIBt is member of EOTA (European Organisation for Technical Approvals).

The actual status is of this approach is:

1. The approach has been generated and the DIBt has decided the accredited test laboratory and the assessor.

2. The test programme has been developed and approved. The test programme includes the test in accordance with categories A, B, C, D and E in behalf of DIN EN 1993-1-8. The clear advantage is supposed for high strength and friction-controlled connections (category B, C and E after DIN EN 1993-1-8.

3. Preliminary and first tests with M27 diameter have been completed.

Download the full white paper from Arconic here.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.